Corundum Brick - Factory Price Wholesale Mullite Corundum Insulating Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Fused Cast Brick

CMAX fused cast alumina (α--β Al2O3 and β Al2O3) firebricks are composed of alpha alumina, beta alumina and a small amount of glass phase.

Feature of Fused Cast Brick

High thermal shock resistance

Good resistance to corrosion of alkali vapor

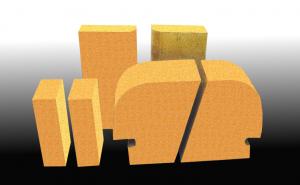

Image of Fused Cast Brick

Technical Data of Fused Cast Brick

FAQ

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Application of electric high temperature regulating valve?

- Now, the definition of refractories has not only depended on the degree of refractoriness is more than 1580 degrees celsius. At present, refractory materials refer to inorganic non-metallic materials used in metallurgy, petrochemical, cement, ceramics and other production equipment lining.

- Q: How much is a thermal brick?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: What are the advantages of refractories?

- Basic refractory material generally refers to Magnesium Oxide or Magnesium Oxide and calcium oxide as the main component of refractory materials. This kind of refractory material has higher refractoriness and strong resistance to alkaline slag.

- Q: What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: Which is good, glazed brick and whole cast glazed brick?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- The sinter plate dust collector is also called plastic plate dust collector. The utility model has the advantages that the utility model can adapt to various complicated working conditions, the dust removal rate is 99.99%, the utility model has the advantages of long service life, stable operation, high temperature resistance, and the utility model is a leading dedusting equipment in china.

- Q: What is the hardness of corundum refractory bricks?

- Corundum refractory brick has good stability against acid and alkaline slag, metal and glass solution. It can be used in oxidizing atmosphere at high temperature or in a reductive atmosphere. The basic material of corundum refractory brick is fused alumina or sintered corundum.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks. Any furnace is not made of only one kind of refractory brick, and it needs different fire bricks to match with each other. The following five categories of refractory bricks are described in detail.

- Q: How do corundum bricks bind?

- High temperature bonding clay can be used for bonding masonry

Send your message to us

Corundum Brick - Factory Price Wholesale Mullite Corundum Insulating Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords