Corundum Brick for Chemical Industry from Chinese Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is Corundum Brick?

l Corundum Bricks are high alumina refractory bricks are made for extreme demands. The alumina content in Corundum Bricks can be traced to the use of synthetic corundum of high purity, such as white fused alumina or tabular alumina. Additional ingredients are special refractory clays, reactive alumina and very pure modifications of silica.

l Corundum Bricks are fired at high temperatures to form a matrix with mullite, mullite-corundum or corundum that has excellent volume stability.

l The service temperature for Corundum Bricks goes up to 1800°C.

What are the applications of Corundum Brick?

Corundum Bricks can be used nearly all fields of industrial application where extreme high temperature and increased resistance against aggressive slags and atmospheres. Such properties or features of Corundum Bricks are necessary especially in the chemical industry and for the production of carbon black. The addition of chromium oxide, zirconium oxide and phosphates lends the bricks excellent structural flexibility, which is required for ash melting furnaces and gas reactors in incinerators.

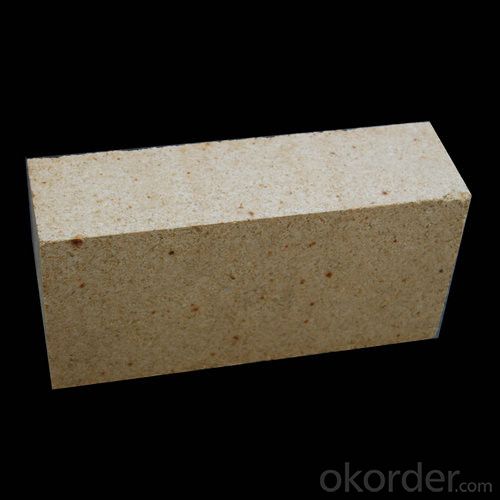

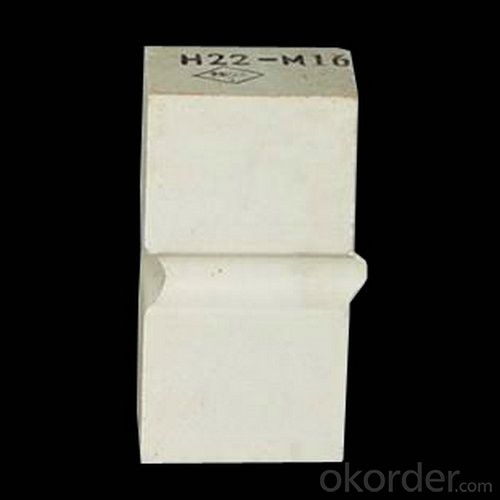

Image of Corundum Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- The compact microstructure of AZS33# zirconia corundum brick makes the bricks resistant to glass liquid corrosion, and it is difficult to produce stone or other defects in the glass kiln. It is the most widely used product in the glass furnace. It is mainly applied to the upper structure of the melting pool, the wall brick of the working pool and the paving brick, the material way, etc..

- Q: Application of electric high temperature regulating valve?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay. Brick is siliceous products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste. The silica acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high, close to the fire, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. The brick is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly used in glass furnace and coke oven silica brick for two categories. Clay brick with refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used in refractory clay brick clay as main raw material is called common clay brick that made pyrojewel clinker as the main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay bricks are divided into several grades according to the physical and chemical indexes. The price difference between the ordinary clay bricks and the low porosity clay bricks is great.

- Q: What material is used in an iron smelting furnace?

- In fact, refractory refractory ah is special ceramic frequently used AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- The peak of new materials in various coal, metallurgy, mines, ports, electricity, building materials and military industry, a lot of workpiece and affect production equipment due to wear, wear resistant materials although rarely cause disasters metal workpiece disaster, but the resulting economic loss is immeasurable.

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- You'll have to invest about about one million if you want an electric furnace. A power distribution room is easiest to approach one hundred thousand. Electric furnaces, power distribution cabinets and transformers must be around one hundred and ten thousand.

- Q: How to improve the induction furnace campaign, from the promotion of refractory life start

- According to the use of atmosphere, choose the appropriate spraying materials, such as infrared radiation paint

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: What is the hardness of corundum refractory bricks?

- Corundum refractory brick has good stability against acid and alkaline slag, metal and glass solution. It can be used in oxidizing atmosphere at high temperature or in a reductive atmosphere. The basic material of corundum refractory brick is fused alumina or sintered corundum.

- Q: High temperature refractory material?

- Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Liquid phosphoric acid two hydrogen aluminum features: easy mixing, molding, especially suitable for field construction, so liquid phosphoric acid two hydrogen aluminum is not flammable

Send your message to us

Corundum Brick for Chemical Industry from Chinese Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords