Factory Hot Sale Colour Coated Aluminium Sheet for 2 Inch Wide Aluminum Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: fascia, shop fronts...

3. Feature of Aluminum

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

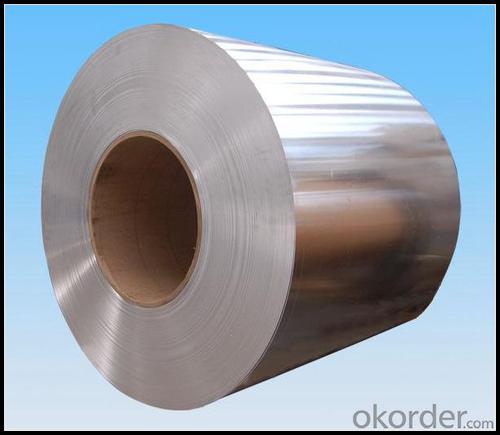

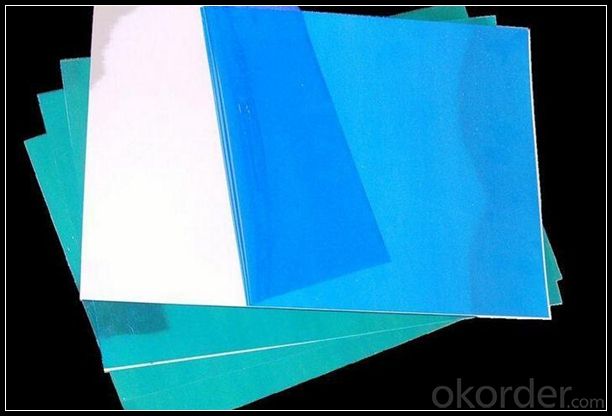

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Explain the distinctions between aluminum foil and aluminum strips in a few sentences.

- <p>Aluminum foil and aluminum strips are both made from aluminum but differ in thickness and application. Aluminum foil is very thin, typically used for food packaging, cooking, and insulation due to its light weight and flexibility. It is also reflective, which makes it useful for cooking and baking. Aluminum strips, on the other hand, are thicker and more rigid, often used in construction, manufacturing, and automotive industries for structural support, heat exchangers, and electrical conductivity. They are not as flexible as foil and are not typically used for food-related applications.</p>

- Q: What is the relationship between the aluminum plate, the aluminum foil and the aluminum alloy strip?

- The concept of aluminum foil and above is the same, but the thickness is not the same, generally considered to be the same product, but the technical requirements of the difference between the two big, divided into two products.

- Q: Is it possible to use aluminum strips as a material for roofing purposes?

- <p>Yes, aluminum strips can be used for roofing. They are known for their durability, corrosion resistance, and lightweight properties, making them a popular choice for metal roofing. Aluminum roofing strips are low maintenance, energy-efficient, and can be recycled, offering environmental benefits. They are also resistant to harsh weather conditions and can last for several decades with proper installation and care.</p>

- Q: This question asks about the various color options available for aluminum strips.

- <p>Aluminum strips are available in a variety of colors to suit different applications and aesthetic preferences. Common colors include silver, which is the natural color of aluminum, black, white, and clear anodized. Additionally, they can be coated or anodized in other colors such as gold, bronze, blue, red, and green. Custom colors are also possible with specialized coating or anodizing processes. The choice of color can depend on the specific use of the aluminum strip, such as for decorative purposes, architectural applications, or industrial uses where color coding is required.</p>

- Q: Is it possible to use aluminum strips for the exterior cladding of a building's walls?

- <p>Yes, aluminum strips can be used for exterior wall cladding. They are lightweight, durable, and resistant to weather and corrosion, making them suitable for exterior applications. Aluminum strips can also be painted or coated to match various architectural styles and can be easily installed. However, it's important to ensure that the aluminum is of high quality and properly installed to prevent issues like water infiltration or structural damage. Always consult with a professional to determine if aluminum strips are the best choice for your specific project.</p>

- Q: Is it appropriate to use aluminum strips for constructing outdoor furniture?

- <p>Yes, you can use aluminum strips for outdoor furniture. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It doesn't rust and can withstand various weather conditions, making it suitable for outdoor use. However, ensure that the aluminum is of high quality and treated to resist UV rays and other environmental factors to prolong its lifespan and maintain its appearance.</p>

- Q: Can aluminum strips withstand harsh conditions like high humidity or salt spray?

- <p>Aluminum strips can be used in harsh environments to some extent, but their performance may be compromised. Aluminum is resistant to corrosion, making it suitable for high humidity conditions. However, in environments with significant salt spray exposure, aluminum can corrode over time, particularly due to the formation of galvanic cells when in contact with other metals. Protective coatings or anodizing can enhance its corrosion resistance, but it's not entirely impervious. Thus, while aluminum can be used in such environments, it requires proper protection and maintenance to ensure longevity.</p>

- Q: Explain the impact of aluminum strips on indoor air quality, including any potential benefits or drawbacks.

- <p>Aluminum strips themselves do not directly affect indoor air quality. They are often used in construction and design for their strength and lightweight properties. However, if aluminum strips are improperly treated or coated with harmful chemicals, they could potentially off-gas and contribute to poor indoor air quality. Additionally, aluminum strips can sometimes be used in conjunction with air purifiers or ventilation systems, where they might help in filtering out pollutants. It's essential to ensure that any materials used in indoor spaces are safe and do not release harmful substances into the air.</p>

- Q: This question asks for criteria to determine if an aluminum strip is still safe and effective for use.

- <p>To determine if your existing aluminum strip is still suitable for use, you should check for any visible signs of damage such as cracks, bends, or corrosion. Ensure that the strip is clean and free from any contaminants that might affect its performance. If the strip is part of a mechanical system, check its dimensions to ensure it hasn't warped or lost its shape. Additionally, consider the strip's age and the conditions it has been subjected to, as prolonged exposure to certain elements can degrade its properties. If you're unsure, consult the manufacturer's guidelines or have a professional assess the strip's integrity.</p>

- Q: Is it possible to utilize recycled aluminum to fabricate new aluminum strips?

- <p>Yes, recycled aluminum can be used to make new aluminum strips. Recycling aluminum is an efficient process that conserves energy and resources. The recycled aluminum is melted down and then reformed into new shapes, including strips. This process is not only environmentally friendly but also cost-effective, as it requires less energy compared to producing aluminum from raw materials. The recycled aluminum strips maintain the same properties as those made from new aluminum, making them suitable for various applications.</p>

Send your message to us

Factory Hot Sale Colour Coated Aluminium Sheet for 2 Inch Wide Aluminum Strips

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords