F Series Triplex Mud Pump Package for Drilling Rig

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of F Series Triplex Mud Pump Description

1) Power End:

The frame is of welded-steel pale construction, with characteristics of high strength , good rigidity and light weight due to internal stress eliminating treatment after being welded .

Integral herringbone gear drive is adopted for smooth running, high efficiency and long operating life. The crank shaft is alloy steel castings.

Double-deck sealing is adopted in intermediate pull rod with sound sealing effect.

The power end adopts the lubricating method of forced lubrication combined with splash lubrication.

2) Fluid end:

The hydraulic cylinder material is alloy steel forging. Straightway hydraulic cylinder has good suction performance.

Suction valve and discharge valve on F series pump are interchangeable.

Pump F-500 uses API 5# valve; pump F-800 and F-1000 use API 6# valve ; pump F-1600 uses API 7# valve.

2. Main Features of F Series Triplex Mud Pump

1) Advanced test for quality

2) MTC provided

3) Good price and service

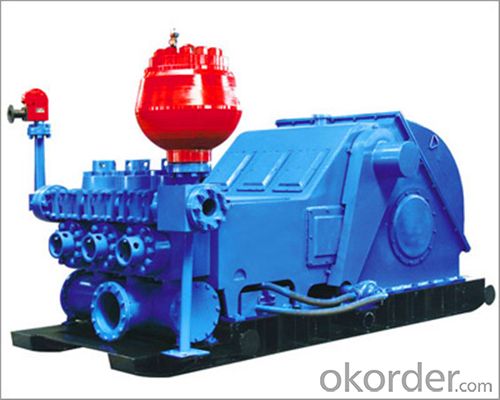

3. F Series Triplex Mud Pump Images

4. F Series Triplex Mud Pump Specification

Model | F-500 | F-800 | F-1000 | F-1300 | F-1600 |

Power kw(ps) | 373(500) | 597(800) | 746(1000) | 969(1300) | 1193(1600) |

Strokes per minutes pm | 165 | 150 | 140 | 120 | 120 |

Stroke mm | 190.5(7.5″) | 229 (9″) | 254 (10″) | 305 (12″) | 305 (12″) |

Gear ratio | 4.286:1 | 4.185:1 | 4.207:1 | 4.206:1 | 4.206:1 |

Max.working pressure Mpa | 34.5 | 34.5 | 34.5 | 34.5 | 34.5 |

Max.Dia.of liner mm | 170 | 170 | 170 | 180 | 180 |

Dia. Of suction pipe mm | 203 | 254 | 305 | 305 | 305 |

Dia. Of discharge pipe in | 4 | 5-1/8 | 5-1/8 | 5 | 5 |

Weight kg | 9543 | 14000 | 18642 | 24572 | 24791 |

5. FAQ of F Series Triplex Mud Pump

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

One of the leading manufacturers and suppliers specializing in this product in China, supply a wide variety of accessories consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: Fire hydrant pump button, under what circumstances do not need to install?

- There are four things to do:Fire hydrant button to meet the requirements of national standards.In addition to pumping, it can show the location of fire.

- Q: What are the uses and precautions of magnetic pumps?

- Notice of use:1. prevent particles from enteringHas the ferromagnetic impurities and particles into the magnetic actuator and bearing friction is not allowed.The transport of crystallization or precipitation of the medium to the flushing (after pumping water, poured into the pump cavity drained after running 1min), in order to ensure the service life of bearing.The transport medium containing solid particles, the pump flow tube inlet filter.

- Q: How can the submersible pump level meter be connected?

- Install liquid level controller, two position liquid level sensor, controller to buy manual, wiring according to wiring diagram.

- Q: How about the depreciation of vacuum pumps?

- (five) electronic equipment, for 3 years.The depreciation period of a vacuum pump can be calculated for 5 years. The expected residual rate is generally 5%, or it can be estimated by itself.

- Q: What are the general water pump failure, how to repair?

- (2) in contact with the water pump inlet of the horizontal application of reverse flow direction, fell more than 0.5% slope, connect one end of the highest import pumps, do not completely level. If the upward tilt, the intake pipe will retain air, reducing the water pipes and pumps in the vacuum, water absorption.

- Q: The difference between diaphragm pumps, vacuum pumps and centrifugal pumps

- The diaphragm works by changing the size of the diaphragm. When the cup is covered with an eraser and the edge is airtight, then pressing the rubber or pulling the rubber outward will make the pressure in the cup increase or decrease. Use this principle, in the pressure of an hour from a hole suction medium, when the pressure is large, from another hole extrusion medium, so as to achieve the purpose of conveying.

- Q: What is the function of the heating pump system for the water pump design?

- Will cause some of the internal friction gap disappeared, the coupling center damage. In this case, starting the pump inevitably results in vibration, friction, etc.

- Q: Roots pump and dry pumpRecently involved in the work of the vacuum pump, don't understand this, is a ads602 vacuum pump, composed of roots pump and dry pump, is pre pumped to the 500mtorr equipment, the main pumping vacuum continues to 10mtorr, where the roots pump and dry pumps must be used? What role they play respectively. The so-called dry pump? Is refers to one kind of the pump, the pump is many dry pump? Also do not understand how the work of automatic switching system for pre pumping, the main pump, pump work alone did not connect system ah (of course there are even a butterfly) teach?

- Different working conditions, our company does dry claw pump alone can also achieve the vacuum of 133 PA.

- Q: Is the flow meter in front of the pump or after the pump?

- After the flowmeter is placed in the pump, it is better to add a pressure tank or a buffer tank, so that the flow meter will work better

- Q: What's the difference between a concrete pump and a concrete pump truck?

- Concrete pump and concrete pump truck are concrete conveying machinery, use the same, but the former need to transport and car towing need additional support pipeline, the locomotive body and arm extends freely, without pipeline, hundreds of thousands of millions of the former, the latter

Send your message to us

F Series Triplex Mud Pump Package for Drilling Rig

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords