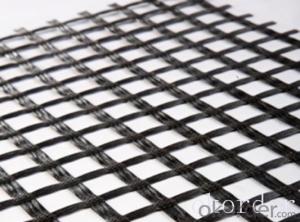

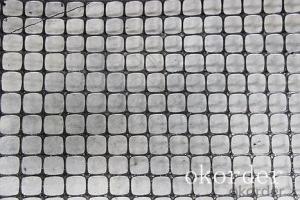

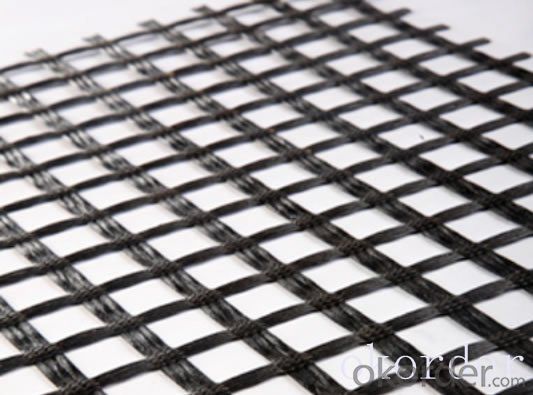

Exeed Geotextile PP Plastic Polypropylene Geogrid Biaxial Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

PP Plastic polypropylene geogrid biaxial

The properties of Biaxial Geogrids, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension. This fact allows them to transfer forces to a larger area of soil than would otherwise be the case.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in erosion control mats?

- Yes, geotextiles can be used in erosion control mats. Geotextiles are often used as a component in erosion control mats to provide reinforcement and stabilization, helping to prevent soil erosion and promote vegetation growth.

- Q: How do geotextiles help with load distribution in bridge approach fills?

- Geotextiles help with load distribution in bridge approach fills by providing reinforcement and stabilization to the soil layers. They distribute the load more evenly across the fill, reducing settlement and preventing differential settlement. Geotextiles also improve the overall strength and stability of the fill, enhancing its load-bearing capacity and extending the lifespan of the bridge structure.

- Q: How do geotextiles help with soil stabilization in steep slopes?

- Geotextiles help with soil stabilization in steep slopes by providing a protective barrier that prevents erosion and helps to retain the soil in place. They act as a reinforcement layer, distributing the load across a wider area, reducing the likelihood of slope failure. Additionally, geotextiles promote water drainage, reducing the potential for saturation and increasing the slope's stability.

- Q: Who knows geotextile, how to sew, the best video

- Sewing machine can be sewn, you can also use hot air gun hot melt, I am specializing in the production of geotechnical materials

- Q: How do geotextiles contribute to the efficiency of drainage systems?

- Geotextiles enhance the efficiency of drainage systems by acting as a filter and separator. They prevent soil particles from clogging the drain pipes, allowing water to flow freely. Additionally, geotextiles distribute the weight and pressure evenly, preventing soil erosion and maintaining the stability of the drainage system.

- Q: What are the different geotextile tensile strength test methods?

- There are several different geotextile tensile strength test methods, including the grab test, strip test, wide-width strip test, and trapezoid tear test. Each method has its own advantages and is used to evaluate the tensile strength and performance of geotextiles in different applications.

- Q: What is the quota of pond compound geotextile cover?

- 500 grams of a cloth or a film or two cloth a film, water depth of 3-5 meters without any problems, and then into a deep reservoir, and then you can use 700 grams of the pond with the Yuanmingyuan do impermeable with 150 / 0.4 Mm, but the general pond 150 / 0.3mm is very good.

- Q: 250 grams of two cloth a film 0.8 thick geotextile what price

- 250 grams of two cloth a film 0.8 thick geotextile per square meter between about 10 yuan -13 yuan, the current price is the lowest in recent years.

- Q: What are the geotextiles?

- contact me

- Q: What does geotextile mean?

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. First, the characteristics: 1, high strength, due to the use of plastic fibers, in dry and wet state can maintain full strength and elongation. 2, corrosion-resistant, in different pH of the soil and water can be long-term corrosion resistance. 3, good water permeability between the fiber gap, it has a good water permeability. 4, good microbial resistance to micro-organisms, insects are not damaged. 5, construction convenience, as the material light, soft, so the delivery, laying, construction convenience. 6, complete specifications: width of up to 9 meters. Is currently the widest product, the unit area quality: 100-1000g / ㎡. Second, the role: 1, isolation 2, filtration 3, drainage 4, reinforced 5, protection 6, anti-puncture

Send your message to us

Exeed Geotextile PP Plastic Polypropylene Geogrid Biaxial Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords