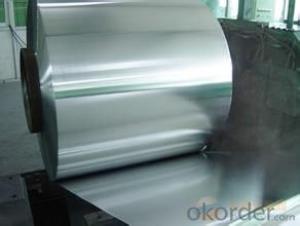

Excellent cold rolled Steel Coil/Sheet -SPCCT-SB

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

Application:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Advantage

1. High Quality SurfaceFinish

2. High Dimensional Precision

3. Excellent mechanicalproperty

Package & Delivery

Package details: Standardseaworthy packing for international delivery.

Delivery: According to theexact quantity of your order.

Images:

Quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many rocessing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing.

- Q: How are steel coils used in various industries?

- Steel coils are used in various industries for their durability and versatility. They are commonly used in automotive, construction, and manufacturing industries for making structures, machinery, and appliances. Steel coils are also utilized in the energy sector for producing power generation equipment and in the transportation industry for making ships and railcars. Overall, steel coils play a significant role in providing strength and reliability in a wide range of industrial applications.

- Q: How are steel coils recycled?

- Steel coils are typically recycled by first being collected and transported to a recycling facility. At the facility, the coils are unpacked and sorted based on their type and quality. Any contaminants, such as oil or paint, are removed through a cleaning process. The coils are then shredded into smaller pieces and melted in a furnace. Once melted, impurities are skimmed off the top, and the molten steel is poured into molds to form new coils or other steel products. This process helps conserve resources and reduce the need for mining new materials.

- Q: 911 conspiacy theorists. Can fire melt steel?

- So does fuel also generate timed explosions that were heard by firemen? Why do we see melting steel that looks like thermite burning? Does the jet fuel also destroy the entire 80 stories of steel support structure as well? (This is required to account for the free-fall speed of the collapse of three buildings. That's right, three buildings collapsed at near free-fall speeds in NYC in the WTC complex.) The government's conspiracy theory is totally inconsistent with the facts. The only theory that has coherence at the moment is the demolition theory presented by Professor Steven Jones of BYU (Physics). I've seen no credible challenges to the 13 points he presented in an academic paper on this topic. I'd very much like to see a credible explanation for the free-fall collapse of all three buildings.

- Q: What are the common uses of stainless steel coils?

- Stainless steel coils are commonly used in a variety of industries for applications such as manufacturing automotive parts, appliances, construction materials, and HVAC systems. They are also utilized in the production of kitchen utensils, medical equipment, and food processing machinery due to their corrosion resistance, durability, and heat resistance properties.

- Q: I have a steel support beam can you remove one of the poles . the steel beam set on sender blocks on both side of the foundation. I have three steel beams support beam across the basement,I just want to remove one pole, can that be done.

- Steel poles under the steel beam is required for the code in your local building area. No, do NOT remove any pole without checking with your local building dept. They are engineered to carry all the weight of the framing over it. If you chose to remove it without checking with the building dept. you can cause a serious structure problem, even a collapse of the structure. Just a phone call to your local building dept. can answer that question. They normally put a steel pole about every 14'-16' depending on the code in your area. There there for a good reason. Think smarter than the next guy, and you will keep yourself safe and your family also. Hoped this helped you go in the right direction.

- Q: Can steel coils be coated with color-changing materials?

- Yes, steel coils can be coated with color-changing materials. These materials are typically applied as a topcoat or overcoat on the steel surface, allowing the coils to exhibit different colors or hues based on external factors such as temperature, light, or chemical reactions. This coating technology can provide visual appeal, aesthetic versatility, and even functional benefits to steel coils in various applications.

- Q: What are the different methods of levelling steel coils?

- Different methods are employed to level steel coils, depending on their specific requirements and applications. Some commonly used methods include: 1. Roller Leveling: This method utilizes a series of rollers to apply pressure on the steel coil, effectively reducing residual stresses and eliminating any waviness or curvature. It is commonly used for achieving high flatness in thinner gauge coils. 2. Stretch Leveling: In this method, the steel coil is stretched beyond its yield point to eliminate shape defects. The coil is subjected to tension in a stretcher leveler machine, which elongates the material and removes inherent stresses. It is often used for achieving greater flatness in thicker gauge coils. 3. Temper Milling: This method involves passing the steel coil through a temper mill equipped with work rolls on top and bottom. The temper mill applies tension to the coil, flattening it and improving its shape and surface quality. It is typically used for higher strength steel grades. 4. Corrective Leveling: When the steel coil exhibits significant shape defects like wavy edges or center buckles, corrective leveling is employed. This method selectively removes material from specific areas of the coil to achieve a flat and uniform surface. Laser or plasma cutting machines are often used for this process. 5. Tension Leveling: Similar to stretch leveling, tension leveling applies tension to the coil without exceeding its yield point. Bridle rolls are used to stretch the material, eliminating internal stresses and leveling the coil. It is commonly used for achieving flatness in higher strength and thinner gauge coils. These methods can be used individually or in combination, depending on the specific requirements and desired end product. Each method has its advantages and limitations, and the choice of leveling method depends on factors such as coil thickness, material properties, and desired flatness.

- Q: What are the commonly used molds steel?

- Usually a hot working grade ( H series ) tool steel is used in die cast mold detail tooling. We typically use H-13 for our applications but have substituted with D-2 on occasion.

- Q: is red steel any good??????? not sure im really impressed but im not really into fighting games but it looks cool.... so whats your views guys???????anyone bored of smooth moves yet?anyone think the new sonic is bit cra ppy !!!!!!!!!!! darn them any new goooood games coming oput on the wii??

- Trauma center is awesome. Red steel isn't bad. Same as any other FPS except with a pointer... It's no half life, but its not terrible. Multiplayer is highly entertaining though. Especially if you can get four people playing mystery mode. Trust me, its worth the effort of getting them together. Like the other guy said, rent it. I wouldn't buy it.

- Q: What are the common coil handling challenges?

- Common coil handling challenges include the risk of coil damage during handling and transportation, difficulties in aligning and positioning coils accurately, issues with coil slippage and instability, as well as the need for specialized equipment to safely and efficiently handle large and heavy coils. Additionally, managing coil edges and preventing injuries to workers are also common challenges faced in coil handling processes.

Send your message to us

Excellent cold rolled Steel Coil/Sheet -SPCCT-SB

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords