Eucalyptus LVL (Laminated Veneer Lumber)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m²

- Supply Capability:

- 3000 CBM per month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

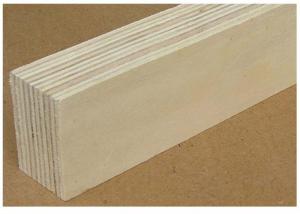

Specifications of the Eucalyptus LVL(Laminated Veneer Lumber)

Species: Eucalyptus

| Size | Wide(Max.1250mm)*length(Max.6000mm) |

| Thickness | Max.50mm |

| Glue | WBP/melamine/MR |

| Material | pine wood |

| Usage | For construction headers, wood beams,rimboard,and edge forming material |

| Grade | A Grade |

| Package | standard export packing, pallet with metal strip |

Introduction of the Eucalyptus LVL( Laminated Veneer Lumber)

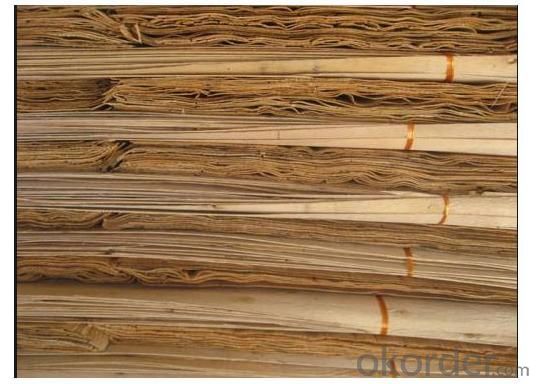

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layersof thin wood

assembled with adhesives. It offers several advantages over typical milled lumber.it is stronger, straighter,

and more uniform. It is much less likely than conventional lumber to warp twist, bow, or shrink due to its

composite nature. Made in a factory under controlled specifications,LVL products allow users to reduce

the onsite labor.

Features of the Eucalyptus LVL(Laminated Veneer Lumber)

1.) High bending strength

2.) little liner expansion con efficient

3.) strong nail holding

4.) moisture proof and easy work

5.) tight construction and high stregth

6.) no ratten or decay

7.) low formaldehyde emission

The usage of the Eucalyptus LVL( Laminated Veneer Lumber)

They are typically used for headers, beams, rimboard, and edge forming material.It is similar in

appearance to plywood without crossbands and is typically rated by the manufacturer for elasticmodulus

and allowable bending stress. Common elastic moduli are 1.8, 1.9, and 2.0 million psi, and common

allowable bending stress values are 2800 and 3000 psi.

The following pictures for your reference.

- Q: Moisture content in laboratory measurement

- Methods for measuring the moisture content of wood are drying method, electric measurement method, dry distillation method

- Q: Building decoration commonly used in wood decorative products which

- Glulam board board, Olsen Sakamoto boardboard, Ou Song board glued together Wood is one of the earliest materials used in architecture and decoration. Woody light, high strength, strong elasticity and toughness, easy processing and surface finishing, especially wood with natural texture, warm visual and tactile feel, which is unmatched by other materials, so they are still in the building Decoration is still occupying a very important position. Here to learn about the basic classification of wood knowledge, as well as home improvement in the common wood products.

- Q: How to completely remove the stickers on wood products

- 4. safflower oil, 2 yuan a bottle, apply to a small area to clear, but also to heal wounds, drugs Well; 5. Warm wax, the price is greater than or equal to 25 yuan, with a towel dipped in water to the surface of the plastic as much as possible first removed, the rest with a coarse wax polished, bright as new;

- Q: How much is the woodworking painting

- Do not know what you have a special request no, my family just done decoration, painting is 35 yuan / square, see how much your arch, too small depends on the master do not do.

- Q: South wet and humid, cabinets, beds and other wood products are shelter are long mold, and how to prevent moldy it?

- I myself is Cantonese, so I also know that the cupboard moldy trouble, especially when the weather back to the South, my computer desk drawer and the like are covered with mold. That my experience is to go to the supermarket to buy a few moisture-proof pills, place in the moldy place.

- Q: Laser marking machine engraved wood products will be black

- In addition, if the performance is unstable, can be offset by the focus of the method can also be improved.

- Q: Wood furniture products which processes need constant temperature and humidity?

- 1, wood drying kiln or wood drying room: there are dry wood raw materials; 2, wood health room or called wood health library: for the semi-finished wood products and temporary storage of health; 3, wood balance or wood balance room: for wood semi-finished products or finished goods before the balance of dry;

- Q: Wood products by polishing and then Varnish, dry after not smooth it?

- The first request in the paint before the 380 # sandpaper with full polished, polished wooden handle surface is smooth without rough feeling,

- Q: garden wood oil - garden wood oil from the preparation of natural raw materials

- mainly for indoor and outdoor wood, such as garden wood products or housing wet areas, to adapt to climate change and humidity requirements

- Q: The Wooden goods maintenance methods

- away from heat, in the cold winter, especially in the north of the people, there will be heating experience.

Send your message to us

Eucalyptus LVL (Laminated Veneer Lumber)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m²

- Supply Capability:

- 3000 CBM per month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords