Supply 8-12mm High Quality Density Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description

Density board (Density Board High (wood)), a kind of plate, according to the density of low density, medium density, high density.

According to the different density, it is divided into high density board, medium density board and low density board. Density board due to the high quality and high impact strength, good after the density is uniform, it is easy to re - processing, the production of furniture is a good material, but the disadvantage is poor waterproof. Medium and high density board, it is the small diameter wood grinding and crushed under high temperature and high pressure to press down, for now the general

2.Product Characteristic

High density board density fibreboard (referred to as high density board (HDF), wood fiber or other plant fiber as raw materials, the applied urea formaldehyde resin, or other synthetic resin by heat and pressure conditions are pressed into a plate. Smooth, in the environment temperature, humidity changes, the size of good stability, easy to surface decoration. Internal organization structure is fine, and is particularly dense edge can be processed into various shaped edge, and do not have direct edge finishing, can obtain good modeling effect. Organizational structure is even and consistent, so it can be for surface carved machining and processing into various sections of decorative lines, suitable for instead of the natural wood as a structural material.

3.Parameter

Product encoding: dngpym8/12E2-830

Product specifications: 8/12*1220*2440mm

Production line: domestic multi-layer production line

Mill: domestic production line

Special process: add wax

Material: Yang Za

Color: light color wood color

Environmental protection grade / glue: E2

Density: 830kg/m fand

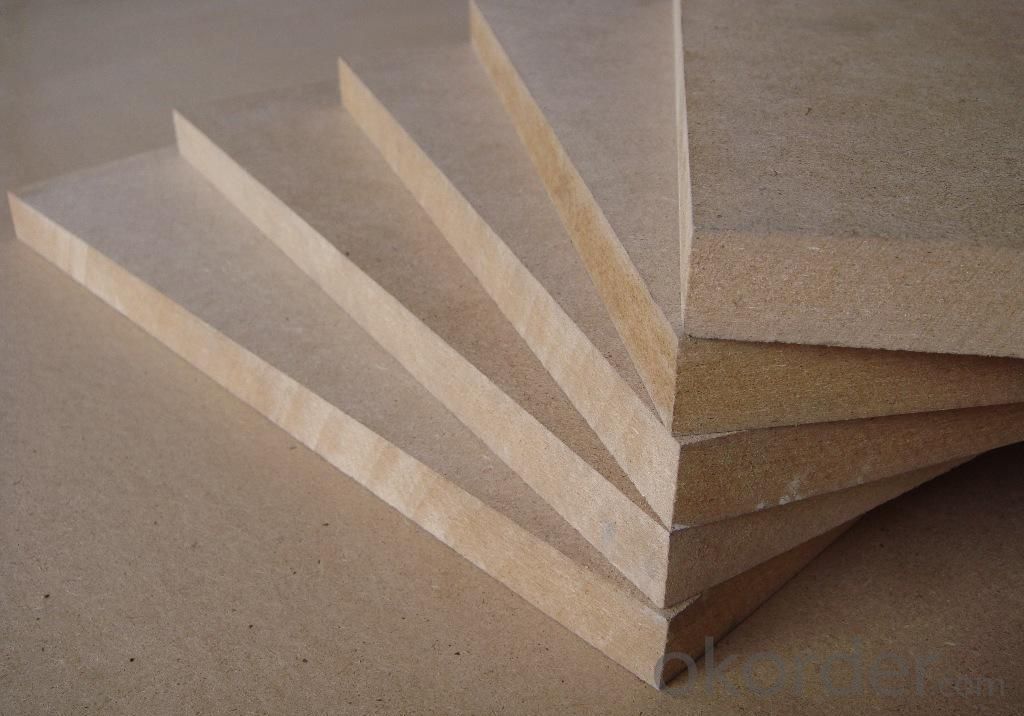

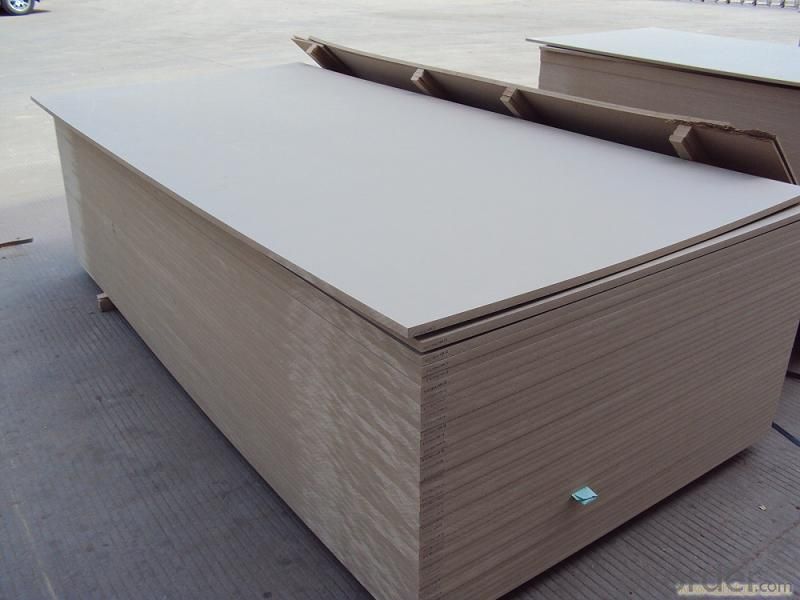

4.Reference Picture

- Q: Why do not you eat wood?

- Because the rats belong to anechoids, their teeth and other animals are different, their teeth back to the continuous growth, if you do not find some harder things to molar, then ... I do not want to say You will know the results! Oh !, more to see the animal world it ~ just fine I just look at the above know.

- Q: How to handle the business license and tax registration certificate for wood products processing plant?

- To carry the company's articles of association, shareholders' meeting resolution, real estate certificate or housing lease contract, capital verification report, shareholder ID card and then go to the Trade and Industry Bureau for business license. Second, carry a copy of the business license to the local Quality Supervision Bureau, for the organization code certificate. Third, carry a business license and organization code certificate to the local IRS, for tax registration certificate.

- Q: Some workers in order to cut corners, in the white latex watered.

- So it was feeling: If only by the appearance of review, the moisture content of wood can be called; immortal difficult to distinguish, steel fire door is made of steel materials, and with fire hardware

- Q: Can wood products go abroad?

- On the plane to carry attention to the goods can not be loaded any liquid any container.

- Q: How does the wood bleach?

- When certain wood or wood products are to be light-colored and transparent, the natural uneven color of the wood and the stain caused by other causes must be removed by bleaching. Bleaching methods are mostly applied with chemical drugs on the wood surface. The bleaching process can be carried out on the entire surface of wood or wood products. More in the local color depth of the wood surface. Bleaching Method The following drugs can be used to bleach wood with a bleach solution.

- Q: What are the benefits of wooden ornaments for the body?

- Wearing red sandalwood: There are some medical books have been mentioned, rosewood after rubbing off the light of sandalwood is conducive to the role of peace of mind, the best mood is good, more beneficial to the function of human organs;

- Q: Can the wall paint brush the colored wood products?

- Temperature: preferably at room temperature (15-30 ℃) conditions, the temperature is too low, paint film becomes slow; temperature is too high (more than 35 ℃), brushing performance will be adversely affected. Humidity: Avoid moist air, most of the paint are not conducive, especially nitro paint, polyurethane paint and so on. In the wet rainy weather construction, will cause whitening or slow drying and other ills. Light: plenty of light will help to see the paint, to identify the construction coating is uniform, in time to avoid leakage brush or sagging, it should be selected in the light of the room for construction. Ventilation: The construction site should have ventilation equipment to maintain the right amount of fresh air circulation.

- Q: How to fill out the export of wood products and wood furniture business self - control situation

- Third, the responsibility of the department Self-control plan by the quality inspection department each year according to the importing country and the customer's product requirements, the company's product type development, approved by the general manager after the implementation.

- Q: Wood preservatives

- 5, transport wood products are leaching and storage warehouse moist with mold survival conditions. When there is suitable for mold survival of nutrients, water and temperature conditions, woody mildew rot will occur. More anti-mildew measures and methods can enter Baidu space.

- Q: What is good for wood preservative coating?

- 1, weathering wood oil - weathering wood oil is a special protection of wood need oil. Mainly applicable to outdoor wood, such as garden engineering, outdoor wood and other preservative. The products are rich in tung oil to make the protective coating on the surface of the wood has a strong ability to adapt to climate change, excellent penetration and adhesion and lasting flexibility, but also particularly resistant to ultraviolet radiation in the sun, significantly delayed The senile deformation of wood, cracking, and does not change the true nature of wood. In the absorption of a normal performance on the board of a layer of oil, the amount per square meter is about 40-70 ml.

Send your message to us

Supply 8-12mm High Quality Density Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords