Poplar LVL (Laminated Veneer Lumber)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m.t.

- Supply Capability:

- 3000 CBM per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the Popular LVL(Laminated Veneer Lumber)

| Size | Wide(Max.1250mm)*length(Max.6000mm) |

| Thickness | Max.50mm |

| Glue | WBP/melamine/MR |

| Material | pine wood |

| Usage | For construction headers, wood beams,rimboard,and edge forming material |

| Grade | A Grade |

| Package | standard export packing, pallet with metal strip |

Features of the High Quality Pine LVL

1.) High bending strength

2.) little liner expansion con efficient

3.) strong nail holding

4.) moisture proof and easy work

5.) tight construction and high stregth

6.) no ratten or decay

7.) low formaldehyde emission

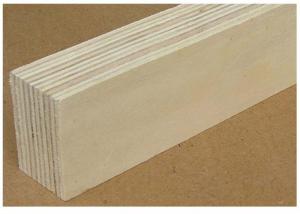

Introduction of the High Quality Pine LVL

Laminated veneer lumber (LVL) is an engineered wood product that uses multiple layersof thin wood

assembled with adhesives. It offers several advantages over typical milled lumber.it is stronger, straighter,

and more uniform. It is much less likely than conventional lumber to warp twist, bow, or shrink due to its

composite nature. Made in a factory under controlled specifications,LVL products allow users to reduce

the onsite labor.

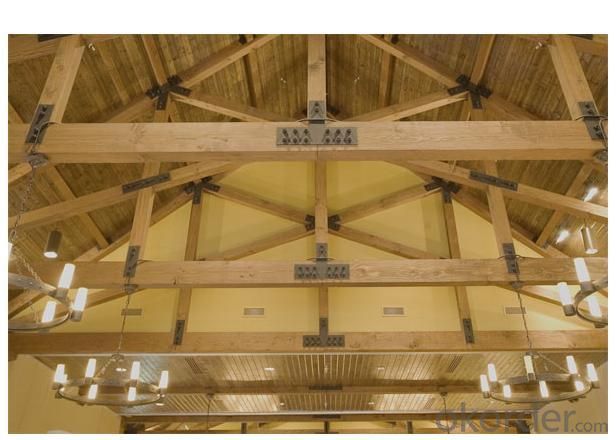

The usage of the High Quality Pine LVL

They are typically used for headers, beams, rimboard, and edge forming material.It is similar in

appearance to plywood without crossbands and is typically rated by the manufacturer for elasticmodulus

and allowable bending stress. Common elastic moduli are 1.8, 1.9, and 2.0 million psi, and common

allowable bending stress values are 2800 and 3000 psi.

The following pictures are for your reference.

- Q: Why do not you eat wood?

- The mouse is an aleks and is different from the teeth of other animals. The teeth of other animals grow to a certain extent will not be long. And the teeth of the rats are long in their lives. If you do not find some hard things to wear short teeth, the rat's teeth will worn lips, affecting survival, so the mice often bite the situation of the wood. In addition to wood, rats occasionally find some other hard things to molars, such as soap and so on.

- Q: Species, fruit, flowers, wood and its products

- Pest species "to fill in all the species of forest pests investigated in this place, may only fill in the Chinese name,

- Q: How to use wood products paint

- 2. White paint, with a base of gray scraping the bottom, the same as above. 3. paint, to use a special colored soil (building materials market have to sell) plug holes, holes, insect eyes nail eyes and other places, and then ibid If it is a traditional paint such as alkyd paint, etc., to the upstairs said the same. Diluted with water that day, spray can be.

- Q: What are the requirements for wood exports to Europe and the United States?

- In recent years, the global timber supply has continued to tighten in the context of countries' tightening of timber export policies. However, the last two years, China's timber imports have been rising sharply, has been caught in the plight of raw materials scarce. At the same time, the introduction of new laws and regulations in Europe and America, but also to many Chinese wood products export enterprises feel pressure. It is expected that the second half of this year, China's timber industry is facing "suffering" will be increasing. This year, the relevant enterprises are really apprehension! Recently, the new regulations introduced in Europe and America to many Chinese wood products export business is quite a headache. Industry experts, the first July 1 this year, the implementation of the United States, "composite wood products formaldehyde standard bill", so that many low-cost market in China's small and medium-sized furniture enterprises feel unprepared, after the introduction of the EU "country of origin label Law "increased the difficulty of furniture exports to the EU. For a time, China's wood products export enterprises in a dilemma.

- Q: South wet and humid, cabinets, beds and other wood products are shelter are long mold, and how to prevent moldy it?

- Or can use a little 84 disinfectant, the cabinet of the moldy wipe clean, and then find a little lime, wrapped in the stack of each layer can be a .. If that is not mold is not possible, your own Also clear our southern weather bar

- Q: Laser marking machine engraved wood products will be black

- In addition, if the performance is unstable, can be offset by the focus of the method can also be improved.

- Q: How to avoid wood deformation

- Whether it is solid wood or man-made sheet, all the wood products contain a certain amount of water. Many consumers think that the more dry the better wood, in fact, this view is biased. Wood moisture content only in the normal range to maintain stability, in order to ensure that the decoration does not appear quality problems. General household use of wood materials, moisture content should be about 8% is appropriate. Water content is too high or too low, will cause the quality of wood in the home improvement.

- Q: How to prevent wood from "dehydrating"?

- 2, construction attention to detail In the home decoration, the quality of wood is the key to the construction, especially the details of the treatment: all wood products in the installation, to immediately brush once again paint. This layer is called "overcoat" paint, not only can protect wood products, but also play a role in isolation of water to maintain the normal moisture content of wood; binder can not be mixed. At present in the home decoration, the general use of white latex for wood products joints of the binder. Some workers in order to cut corners, in the white latex watered. This not only reduces the strength of the binder, and wood products absorb moisture, it is prone to quality problems; all the wood to be placed for a few days. You in the decoration with the wood to buy home, the best place in the decoration site for a few days and then use. The purpose of this is to make the moisture content of the wood close to the level of new homes.

- Q: Wooden products marked above the letter engraved pattern with what machine equipment?

- Carbon dioxide laser marking machine in the wood above the standard color is generally black, marking no other colors. Software compatible formats are jpg, ai and so on. After the installation of the corresponding fixture can be carried out in different shapes of wood surface

- Q: Wood products waxing

- 1, after waxing will be bright, bright color. Before waxing the best thorough cleaning, keep no dust, no foreign body.

Send your message to us

Poplar LVL (Laminated Veneer Lumber)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1X20' FCL m.t.

- Supply Capability:

- 3000 CBM per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords