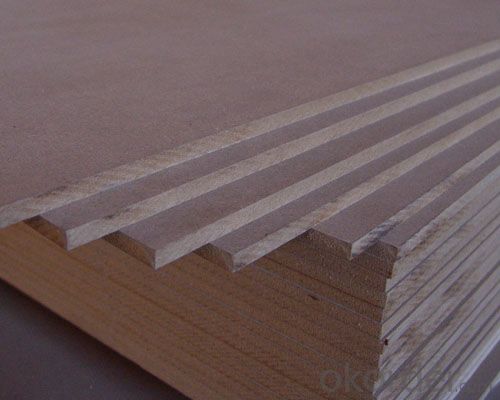

E2 High Density 1220*2440mm Regular Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description

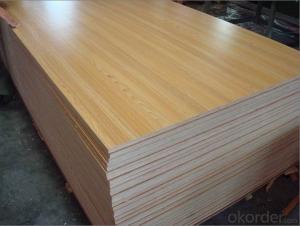

Density fiber board (referred to as high density board HDF), wood fiber or other plant fiber as raw materials, the applied urea formaldehyde resin, or other synthetic resin by heat and pressure conditions are pressed into a plate. Smooth, in the environment temperature, humidity changes, the size of good stability, easy to surface decoration. Internal organization structure is fine, and is particularly dense edge can be processed into various shaped edge, and do not have direct edge finishing, can obtain good modeling effect. Organizational structure is even and consistent, so it can be for surface carved machining and processing into various sections of decorative lines, suitable for instead of the natural wood as a structural material.

2.Product Characteristic

High density fiber board with its outstanding performance in the physical, compatible with the all the advantages of MDF, widely used in indoor and outdoor decoration, office, high-grade furniture, audio, senior car interior decoration, but also can be used as a computer room antistatic flooring, wall panel, anti-theft door, wall panels, partitions and other materials. It is a good material for packaging. In recent years, it is to replace the direct processing of high-grade hardwood flooring, flooring; also used in transportation of goods shelf above protection, and modern home decoration without frame painting, such as national registered trademark visual life frameless painting is so used, to home life more environmental protection.

3.Parameter

Product Code: dnjgndNE2-800

Product specifications: 2-5mm*1220*2440mm

Production line: rolling thin plate production line

Mill: Su Fuma

Material: Yang Za

Color: light color wood color

Environmental protection grade / glue: E2

Density: 800 fand kg/m

Class I

Moisture content: less than 12%

Apparent density: 800

Bending strength: more than 17.2MPa

Special features: not easy to split

4.Reference Picture

- Q: Do you want to do electrostatic spraying?

- No, electrostatic spraying is mainly used for the spraying of metal objects, because electrostatic spraying is required to spray and spray objects and the formation of the ground loop to complete the spray, dry wood conductivity is not good, so can not, and there are too many wood resin class

- Q: Wood products how to minimize the cost of color and brush once can not repeat the brush or do not fade Oh

- This work requires a considerable level of skill in the paint tool to do well.

- Q: Can wood products go abroad?

- To Japan to go with wood products no problem, as long as it is not overweight, the volume is not particularly large circumstances are allowed. Even overweight only pay excessive freight only. (Overweight cost is very expensive oh)

- Q: How does the wood bleach?

- Second, sodium bisulfite, first with the following two solutions. 1, the sodium bisulfite dubbed saturated solution. 2, in 1000 ml of water dissolved 6.3 grams of crystalline potassium permanganate. When used, first potassium permanganate solution coated on the wood surface, about 5 minutes, slightly dry, and then coated sodium bisulfite solution, repeat the above operation until the wood white. [PAGE] Third, bleaching powder, it has the following two methods of use. 1, the first dubbed 5% potassium carbonate and sodium carbonate (1: 1) 1 liter of aqueous solution, then add 50 grams of bleaching powder, with this solution brush the surface of wood, to be bleached with 2% soapy water or dilute hydrochloric acid solution clear...

- Q: Fiber laser marking machine can play wood material?

- Fiber laser marking machine can not play wood products. Wood products are generally marked with CO2 laser ? CO2 laser marking for the largest number of non-metallic materials marking, such as paper packaging, plastic products, label paper, leather fabrics, glass ceramics, resin plastic, bamboo products, PCB board.

- Q: What kind of adhesive for wood products

- AB glue is called two-component adhesive. Commercially available acrylic, epoxy, polyurethane and other components of the AB glue. When used in the factory, it is referred to as AB glue (the name on the box), which is different from the conventional large-size clothing (1 kg / 2 kg group) epoxy resin. Instructions

- Q: Is the wooden product environmentally friendly?

- Wood products are made of wood raw materials, processed, the formation of the product.

- Q: How to identify genuine and genuine peach products

- Soaked with salt water can add the taste of peach, but also emit a peach taste, false peach without this feature.

- Q: There are some tips, can help you sure whether the moisture content of wood pass.

- And the high moisture content of the material is heavier, feel cold, pushing the planing sound is not brittle, or even shaving wate

- Q: Wood products in what kind of temperature and humidity placed the most appropriate?

- Temperature: +5 to + 35 ° C ? 2. Humidity: no more than 85% RH ? 3. Atmospheric pressure: 80KPa when 106KPA Avoid direct sunlight or other direct heat radiation. ? 5. Flammable, corrosive gas environment. ? 6. Strong turbulence and convection around a strong electromagnetic field, strong vibration effects.

Send your message to us

E2 High Density 1220*2440mm Regular Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords