Reynolds Wrap Aluminum Foil Costco Insulated Ducts Epoxy Coated Aluminum Foils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

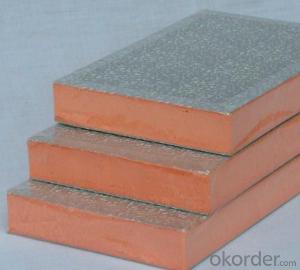

1. Structure of Epoxy Coated Aluminum Foils Used for Insulated Ducts

We specialize in epoxy coated aluminum foils used for insulated ducts. Our coating include blue color, transparent color, gold color, silver color, etc.

Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam. Usual width include 1210mm, 1215mm, 1270mm, etc.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Epoxy Coated Aluminum Foils Used for Insulated Ducts

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

3. Epoxy Coated Aluminum Foils Used for Insulated Ducts Images

4.Specification of Epoxy Coated Aluminum Foils Used for Insulated Ducts

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: I just went to one of my weekly doctor appointments and I was still 3cm dialated for the second week in a row, so she told me different natural ways that I could help induce labor since I didn't want my membranes strippedShe said drink red raspberry leaf tea and have sexSo my husband and I have been having sex and I've been walking at least once a day for half an hourI just went out and bought the tea, but I was wondering how much I should actually drink for it to work, and also how much sex and walking should I be doing for it to also work? If some one knows the answer, or knows where I can search for these answers, it would be greatly appreciated.

- I bought a Zebco 11 not too long ago and it's greatSmall tooThe reel is even smaller than the toy fishing rodsI put it side by side my little nephews Spiderman rod and mines rod is only 6 longer and the reel is smaller! But I guess you're looking for a bigger reel than that thoughI think the young ones will enjoy the pistol grip rodsIt's easy for them to palmA spin cast reel is a mustSome kind of light action pistol grip rod will do fine4'6-5'6 is a good lengthCheck out the Zebco 22It's between a 33 (the new ones are mighty big) and an 11 (it's teeny tiny)Wal-Mart sells an all graphite casting rod with pistol grip for like $20It's niceLight as heck tooThe Ugly Stik Jris a good choice too!

- Q: -Its metal-Aluminum.-It preserves.-You can fit a person inside.-Oil.Any idea what this could be?Thanks!

- I go around my city and ask for restaurants for there used cooking oilThat's my green job.I take the oil to be turned into bio-Diesel.

- Q: I was wondering if you can refrigerate a can of food, say fruit or soup, in the aluminum can it is inI heard that it is not good to refrigerate in aluminum containersIs this true?

- It is not good to store open aluminum cans in the fridgeIn my state it is it is against the health code to do it in food Establishments(I would hope it is in all states)Leaving food in the can and placing in fridge can cause the metal to leach and cause poisoning and growth of harmful bacteria.

- Q: There's a recycling bin at my house and I've never had one before, since I'm very environmentalist I try to recycle as much as I can, but I don't know what and what not to throw in th recycling bin, help me!!!!!!!thanks X ]

- Different areas (councils in the UK) offer different recycling facilitiesGive them a call to find out what you can do in your area Beyond the green box, you can recycle most things if you have a mind to! But don't forget, you can also reuse things (especially plastic bags and bottles, glass jars) before you recycle them which is even better! By reusing lots of these things, it also means you don't need to buy new thingsWhy buy a plastic container when you get one free with pasta sauce (glass or plastic), for example? Get creative with your waste and make cool stuff - web link below for more ideasGreat that you're green! Keep up the good work!! :-)

- Q: In chemistry I have to find how thick a sheet of aluminum foil isThe sheet is 10X10 cm and I don't know how else to figured out the thickness? Please helpEmail if you have any questionsPleaseee.

- There are many ways you could go about doing this depending on what equipment you have at your disposal, or what your aim is with the piece of foilI suppose the extremely easy method would be to take a precise caliper of some sort to measure the thickness of the foil directly, but I would imagine that's not what the goal of the assignment isI would imagine that your textbook has a value in a table in the back for the density of aluminum? If it does, then if you take the mass of your aluminum foil sheet, you would know its volumeSince you know that it is 10cmx10cm, it has an area of 100cm^2, you can find the thicknessYou would take volume of aluminum divided by area of one side to get thickness.

- Q: I'm making Carrot Cake Bars and I'm wondering if I put aluminum foil at the bottom of the pan will it interfere with the baking?

- One of the only really good things about fiber is that it is a carbohydrate that cannot be digestedThe healthy status of fiber was simply created as a marketing ploy several decades ago based on false unscientific information Think of fiber like eating a piece of paperYour body cannot digest cellulose, so it simply passes through youI'd rather eat something that doesn't just pass through me.

- Q: ok so i made a home made diffuser for my hair dryer - out of wire and tin foil - kinda like a foil lamp shade with a covered end with holes poked in it.simply because i cannot find a diffuser sold separate around here.so my dryer has 2 setting low and high and the foil gets hot ( but so dose the plastic dryer) what i want to know is will there be some kind of electric problems since its aluminum foillike over heat and bust the fuse box? or spark?

- If you've only stuck foil to the outside of the dryer there should (note the weasel-word) be no electrical hazardAll the electrical parts should be safely housed inside where you can't get to themIf you've stuck anything up the barrel of the dryer to attach your diffuser I'd be worriedBad idea! The biggest hazard, from where I sit, is heatIt is possible for the foil to get hot enough to cause burnsAluminum will absorb and hold heat much better than plastic, so it can get much hotter than the plastic caseBe very careful.

- Q: Are there any recipies and how do you fillet them, are they good eating?

- Sounds like you got ripped offI got my Central Air/Furnace, High efficient system when they we giving creditsI think I paid close to 4K.

- Q: i am having difficulty finding a pi shaped cooking pan onlinei would like to bake a cake in the shape of my favorite number :)

- yeah probably because it doesnt exist either cut a cake into the pi shape yourself or decorate a pi symbol with frosting on a cake

- Q: i have used gluten free as i didn't realize there was a different from my normal baking powder as the packaging is the sameWhen i got my cake out of the oven, something looked differentThe cakes are flatter and breaking apart can anyone help me ?

- Are you sure it wasn't aluminum free? Aluminum free bkng powder is becoming popular now that aluminum has been linked to Alzheimer diseaseMost aluminum free is single acting, most with aluminum is double acting.

Send your message to us

Reynolds Wrap Aluminum Foil Costco Insulated Ducts Epoxy Coated Aluminum Foils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords