EPDM Rubber High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

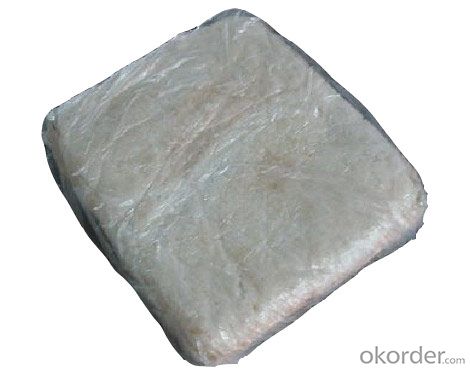

1. Description of Rubber:

Natural rubber is a kind of polyisoprene as the main component of natural high molecular compound, its composition in 91% ~ 94% is the rubber hydrocarbon(polyisoprene), the protein, fatty acid, carbohydrate, ash and other non rubber substance. Natural rubber is the most widely used general rubber..

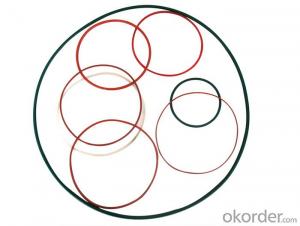

2. Main features of Oil Seal:

1) High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum.

2) high elongation, the maximum can reach more than 1000%.

3) the elastic modulus and the shear modulus is low, than some rigid substances such as iron and steel and other low much.

4) cold resistant, the glass transition temperature of minus 72 degrees..

3. Rubber Images:

4. Rubber Application:

Rubber elasticity, good insulation, impermeability and plasticity characteristics of natural rubber, and through the mix after appropriate treatment also has oil resistance, acid and alkali resistance, heat resistance, cold resistance, pressure resistance, wear resistance and other properties, therefore, has the widespread use, mainly used for automobile, machinery, industrial etc. industry as a shock, sealing parts.

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rubber is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What rubber material is HVA-2? Is it environmentally friendly?

- In natural rubber, and sulfur, can prevent reversion, improve heat resistance, reduce the heat aging resistance, improve the adhesion of rubber and cord and rubber modulus. For load tire shoulder rubber, rubber cushion layer, which can solve the problems of bias truck tire shoulder space, also can be used for natural the large size and thick rubber products and a variety of rubber goods.

- Q: What's the difference between the lining material and the rubber? What media are applicable?

- The lining material of the valve lining has seen what material, and some are ceramic, generally water resistant! Oil should be lined with nitrile rubber or oil resistant paint!! Specific use of material is not the same!!

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials?

- HNBR has a high temperature resistance of 130~180 degrees, cold resistance of -55 ~ -38 degrees, and good mechanical properties, compared with other polymers, can meet the requirements of the automotive industry. HNBR with ZnO/ methacrylate (MAA) can be used to make V-belt, triangular V-belt, multi base rubber, vibration isolator and so on. It can also prepare sealing ring, sealing element, heat resisting tube and so on. In oil drilling, rubber products are required to withstand high temperature, high pressure, acid, amines, H2S, CO2, CH4 and other tests of steam. The products prepared by HNBR can be acid resistant, oil resistant and solvent resistant. With the ZnO/MAA HNBR reinforcement can be used for the production of drilling mud pump piston and protection box. In addition, the beating method HNBR can be used as a sealing washer washer made of paper oil industry and automobile industry. HNBR heat and radiation resistance properties than silicon rubber, fluorine rubber, poly four vinyl chloride is better, suitable for all kinds of rubber seals for power station, is also used as a hydraulic pipe, hydraulic seals, power station for cable sheath, can also be used for printing and fabric roller, weapons components and aerospace seals, cover, fuel capsule; HNBR latex can be used as a surface coating (painting), textile, paper, leather, metal, ceramic fiber, non-woven adhesive, and foam rubber, latex impregnated products etc.. In addition, with ZnO/MAA, peroxide and high wear furnace HNBR, its comprehensive performance is better than ordinary HNBR.

- Q: What are the functional differences between plastic and rubber?

- Plastic materials (LC plastic raw materials wholesale, high temperature resistant plastic material, PPS, LCP, PET, PA, PES plastic raw materials suppliers): the main ingredient is resin, is made of polymer resin as main ingredients into a variety of auxiliary material or adding agent, at a certain temperature, with plastic and motor can be under pressure molded into shape and maintain the same shape of material under certain conditions;

- Q: How about liquid rubber waterproof coating?

- Compared with the traditional SBS waterproofing membrane and high polymer polypropylene waterproofing membrane, the appearance of liquid rubber waterproof coating is of great importance to the waterproof field.

- Q: Why are synthetic rubber not composites?

- The composite material is formed by composite technology to a certain combination of two or more than two kinds of different properties and different forms of constituent materials of a multiphase material, which can not only maintain the main features of the original component materials, has demonstrated the new performance of the original component materials are not. There is no reinforcing phase in synthetic rubber

- Q: What are the main ingredients of synthetic rubber?

- There are many kinds of synthetic rubber, each of which is different in material and, of course, mainly olefins and their derivatives. The answer to styrene butadiene rubber is one of the most widely used

- Q: What are the materials that are prone to static electricity? Can rubber friction generate static electricity?

- The principle of antistatic gloves is that there is conductive wire or fabric with conductive liquid and so on

- Q: What's the difference between plastic, EVA and rubber? Choose sandals and good material

- Plastic, EVA, rubber, sandals, EVA, good material, light.

- Q: What are the advantages and disadvantages of silicone?

- It is worth mentioning that in biomedical engineering, polymer material plays a very important role, and the silicone rubber is a kind of important medical polymer materials, it has excellent physiological inert, non-toxic, tasteless, non corrosive, anti coagulation, and the good compatibility, can withstand the harsh conditions of sterilization. According to the requirements, it can be processed into pipes, sheets, films and special-shaped components, which can be used as medical instruments, artificial organs and so on. Nowadays, there are special medical grade silicone rubber both at home and abroad.

Send your message to us

EPDM Rubber High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords