O Ring Rubber High Elasticity, According To The Formula

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Rubber:

Natural rubber is a kind of polyisoprene as the main component of natural high molecular compound, its composition in 91% ~ 94% is the rubber hydrocarbon(polyisoprene), the protein, fatty acid, carbohydrate, ash and other non rubber substance. Natural rubber is the most widely used general rubber..

2. Main features of Oil Seal:

1) High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum.

2) High Elongation, The Maximum Can Reach More Than 1000%.

3) The Elastic Modulus And The Shear Modulus Is Low, Than Some Rigid Substances Such As Iron And Steel And Other Low Much.

4) Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

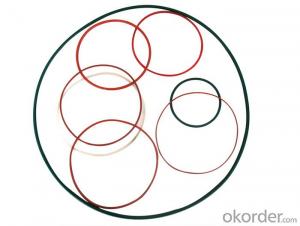

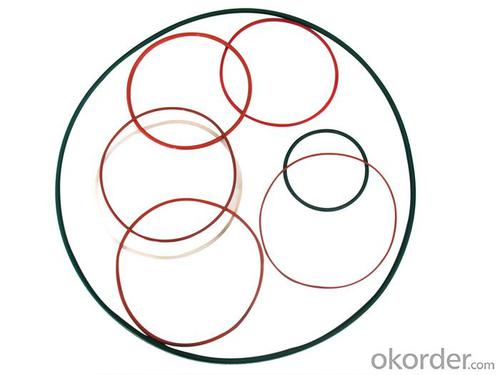

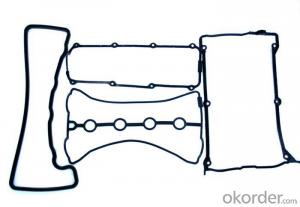

3. Rubber Images:

4. Rubber Application:

Rubber elasticity, good insulation, impermeability and plasticity characteristics of natural rubber, and through the mix after appropriate treatment also has oil resistance, acid and alkali resistance, heat resistance, cold resistance, pressure resistance, wear resistance and other properties, therefore, has the widespread use, mainly used for automobile, machinery, industrial etc. industry as a shock, sealing parts.

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rubber is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the function of the rubber on the left and right sides and the back of the chassis?

- This is called an anti Sassafras strip, mainly scratch proof

- Q: What are the applications of rubber airbags in the automotive field?

- Conveyor beltThe most common belt in a car is a synchronous belt used to drive the crankshaft cam synchronously. Compared with the metal chain, the synchronous belt can effectively reduce the contact noise with the sprocket, and does not need lubrication, and has the characteristics of light weight. At the same time, due to its flexibility, it can also be applied to multi axle drive. In Japan, more than 70% of cars use synchronous belts, while in Europe it is as high as 80%. Previously, rubber synchronous belt has been covered with neoprene (CR). Nowadays, a large number of studies have found that hydrogenated butyl rubber (HNBR) has better performance, so more applications have been obtained in automobile synchronous belt. HNBR has superior properties than CR, complex modulus, good stability and low temperature performance, heat resistance and ozone resistance, excellent flexing resistance and good oil resistance in a wide temperature range. In the test of tape function, hydrogenated rubber (HNBR), compared with chloroprene rubber (CR) covering rubber, has a heat resistance level of 40 DEG C at the same operation time. At the same time, the life of HNBR is 2 times that of CR.

- Q: How does the new car remove the smell of rubber in the car?

- The new special odor eradication agent living skin get rid of formaldehyde solution, can effectively remove the odor inside the car.

- Q: How to maintain the tires?

- Tyres are basically made of rubber. And elastic rubber, most afraid of the deterioration of the external environment, resulting in deterioration of rubber. The most common situation is rubber hard, loss of elasticity, finally caused some serious cracks, even a mole from tread peeling.

- Q: Method for machining polyurethane rubber by lathe Too elastic

- Choose the higher hardness of the plate or bar, the processing speed is slow, so that processing is easy to point

- Q: What are the rubber parts used in the automotive suspension system?

- Suspension is the floorboard of all the force coupling devices between the frame (or load type body) and the axle (or wheel). Suspension is the role of the various forces acting on the wheel of the pavement and the torque transmitted to the frame (or body type), absorption and ease caused by the uneven pavement driving wheel and frame to beat shock and vibration.

- Q: What is the swelling glue used in automobiles?

- Typical use:The utility model is suitable for the shock absorption and bonding between the automobile sheet metal and the stiffener, the framework and the support frame. Shock absorption of door, body, outer panel, outer panel and frame.Advantage:Easy construction, excellent adhesion on oil surface.High expansion rate, good adhesion, elasticity, sound absorption, shock absorption and noise reduction results from tightness.

- Q: Horsen armored vehicle chassis paint spray type construction site vehicle anti rust paint drying glue please chassis armor

- It is non-toxic, high covering rate, high adhesion, can be sprayed on the vehicle chassis, wheel hub, oil tank, automobile panels, luggage and other exposed parts, fast drying to form a layer of strong elastic protective layer can prevent the stone and gravel impact, avoid moisture, acid rain, salt erosion of metal for vehicle chassis, prevent rust and corrosion protection of the chassis, the owner of the traffic safety.

- Q: Can the waterproof sealing strip for sunroof glass be changed?

- Pay attention to waterproof of skylight.Operation 1: carefully clean the rubber strip of the skylight every year. The moving part of the skylight is made of low maintenance material. The mechanical parts should be cleaned regularly with oil or lubricant. It is recommended to be cleaned every two months.The roof of the seal is rubber seal, in the use of the process should pay attention to dust seal, especially after the winter or experienced long, often must dust cleaning dust. Also, be careful not to open the sunroof under the condition that the roof is frozen. This will damage the sunroof motor. In windy and windy season, it is necessary to clean the seal ring with sponge every two months.Operation 2: in the car wash process, avoid using high-pressure water gun to direct the water column to the sealing ring.In this way, it is not only easy to deform the sealing ring under the pressure of the high pressure water column, but also to enter the water in the car and damage the sealing ring to a great extent.

- Q: Are automobile tyres natural rubber or synthetic rubber?

- Bonded carbon particles and rubber molecules is very good, which enhances the rubber hardness, strength and wear resistance. The carbon black and rubber tire from the basic volume, main material is actually a kind of composite material of rubber and carbon black.

Send your message to us

O Ring Rubber High Elasticity, According To The Formula

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords