Acrylate Rubber Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Rubber:

Natural rubber is a kind of polyisoprene as the main component of natural high molecular compound, its composition in 91% ~ 94% is the rubber hydrocarbon(polyisoprene), the protein, fatty acid, carbohydrate, ash and other non rubber substance. Natural rubber is the most widely used general rubber..

2. Main features of Oil Seal:

1) High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum.

2) High Elongation, The Maximum Can Reach More Than 1000%.

3) The Elastic Modulus And The Shear Modulus Is Low, Than Some Rigid Substances Such As Iron And Steel And Other Low Much.

4) Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees..

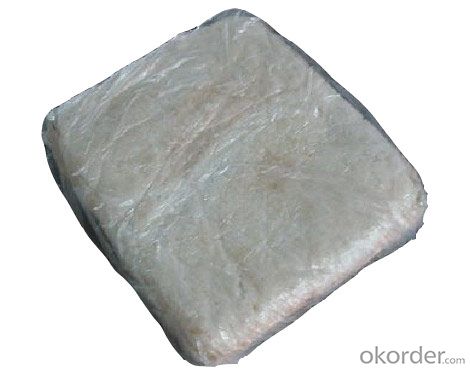

3. Rubber Images:

4. Rubber Application:

Rubber elasticity, good insulation, impermeability and plasticity characteristics of natural rubber, and through the mix after appropriate treatment also has oil resistance, acid and alkali resistance, heat resistance, cold resistance, pressure resistance, wear resistance and other properties, therefore, has the widespread use, mainly used for automobile, machinery, industrial etc. industry as a shock, sealing parts.

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rubber is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How to accurately determine the corresponding rubber tire rubber powder mesh material?

- 120 items: insulation material, plastic pipe additive, special packing for shoe making, chemical sealant, automobile retreading outer cushion, automobile oblique tyre auxiliary material and various rubber seepage mixture.200: car tires, paint, building materials production of various rubber products, rubber substitute.

- Q: What is the difference between TPU material and silica gel material?

- [alias]: silica gel, silica gel is a kind of high active adsorption material, belonging to the amorphous material, its molecular formula is mSiO2 nH2O; in addition to alkali, hydrofluoric acid does not react with any material, insoluble in water and any solvent, non-toxic, chemically stable. Different types of silica gel have different microporous structures because of their different manufacturing methods. The chemical composition and physical structure of silica gel determine that it has many characteristics which are difficult to be replaced by other similar materials: high adsorption properties, good thermal stability, stable chemical properties, high mechanical strength, etc..

- Q: Oak, Manchurian ash, ash wood, pine wood, rubber wood material which is best? What are the characteristics?

- Rubber wood texture is not better than nanmu pine hardwood clearBottom layer: fir, pine, camphor woodRosewood and rosewood are only legendary. Too little. I can't afford it anyway

- Q: What kind of material is the bottom of flip flops? Foam or rubber?

- Our country also has sales now, mainly Havaianas (Havana) and ipamema (Bea Pane Mar).

- Q: What kind of rubber material can reach 700% elongation rate?

- Natural glue can be, in general, is about 500, but to high elongation can also, the formula adjustment can meet the requirements. Natural rubber maximum elongation, I have done more than 1000%. It's not a problem. Don't use the best glue, either.

- Q: What kind of material is the sealing ring on the bearing?

- NBR oil resistance of nitrile rubber is the best in the general rubber, nitrile rubber and hydrogenated nitrile rubber with more excellent oil resistance, oil resistance, but if your request is not too harsh words with NBR, HNBR because the price is relatively expensive.

- Q: What material is the line on the rubber court floor? What's the practice?

- Sports floor installation process, the first step: pavement alignment seamThe second step: check the alignment seamThe third step: put the belt (1/2)The fourth step: put the belt (all)

- Q: Compression permanent deformation of rubber material is not the same concept as dimensional stability

- The compression rate of permanent deformation is compressive deformation capacity determination of foaming material and rubber and other soft materials, it relates to the vulcanized rubber and elastic recovery, in particular are generally known height samples, according to the compression rate requirements compressed to a specified height and keep under specified conditions of temperature for a certain time, then lift let the free state under compression, sample response, measuring samples within the time specified in the height, and then through the formula to calculate the compression rate of permanent deformation.

- Q: Is vulcanized rubber thermoplastic or thermosetting?

- Thermoplastic rubber is a mixture of traditional vulcanized or uncured thermosetting rubber (e.g. EPDM) and rigid thermoplastics (such as polypropylene or polystyrene)

- Q: What is silicone foam material for?

- Characteristics of silicone rubber foaming material:1, high foaming times, uniform foaming and good stability;2, there is no toxicity and corrosiveness;3, light quality, flexibility, feel good;4, there is no migration phenomenon.

Send your message to us

Acrylate Rubber Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches