Aluminum EN AW-5005 DC Aluminium Circle for Deep-Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 5005 DC Aluminium Circle for Deep-Drawing Description

EN AW - 5005 DC Aluminium Circle for Deep-Drawing is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 5005 DC Aluminium Circle for Deep-Drawing

EN AW - 5005 DC Aluminium Circle for Deep-Drawing | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 5005 DC Aluminium Circle for Deep-Drawing

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 5005 DC Aluminium Circle for Deep-Drawing

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 5005 DC Aluminium Circle for Deep-Drawing

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

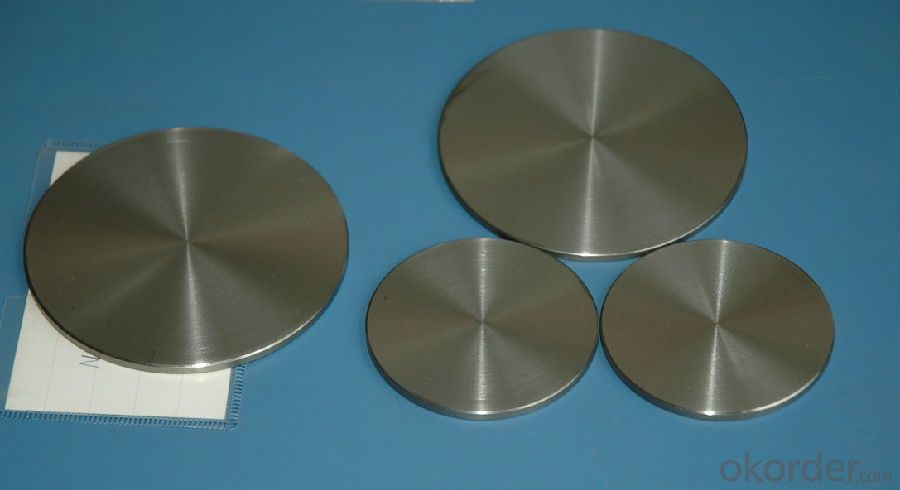

6. Image of EN AW - 5005 DC Aluminium Circle for Deep-Drawing

7. Package and shipping of EN AW - 5005 DC Aluminium Circle for Deep-Drawing

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is aluminum a suitable material for construction purposes?

- <p>Yes, aluminum is widely used in building materials due to its lightweight, high strength, and corrosion resistance. It is common in window frames, roofing, facades, and structural components. Aluminum's malleability allows for versatile design, and its recyclability makes it an environmentally friendly choice.</p>

- Q: Explain how the use of aluminum contributes to global warming in a few sentences.

- <p>The use of aluminum significantly affects global warming due to the energy-intensive process required to extract it from bauxite ore. The production of aluminum releases large amounts of greenhouse gases, particularly carbon dioxide, which contribute to global warming. Additionally, the electricity used in aluminum production often comes from fossil fuels, further exacerbating the issue. Moreover, aluminum is lightweight and durable, leading to increased demand, which in turn drives up production and emissions. The recycling of aluminum is crucial to mitigate its environmental impact, as it requires only 5% of the energy needed for primary production, significantly reducing carbon emissions.</p>

- Q: This question asks for various methods that can be used to recycle aluminum.

- <p>Recycling aluminum can be done through several methods, including mechanical recycling, which involves melting and reprocessing aluminum without altering its chemical properties. This is the most common method due to its efficiency and cost-effectiveness. Another method is chemical recycling, where aluminum is treated with chemicals to break it down into its constituent elements, which can then be repurposed. Additionally, aluminum can be recycled through a process called hydrometallurgical recycling, which uses aqueous solutions to extract aluminum from waste. Finally, sorting and collection play a crucial role in ensuring that aluminum waste is directed to appropriate recycling facilities where these methods can be applied.</p>

- Q: Besides other special pots, can other aluminum pots be used?

- Aluminum pots are not working wellChasing the answerAluminum pots are not working wellStainless steel pots available.

- Q: This question asks about the potential dangers associated with exposure to aluminum through consumption of food and drinking water.

- <p>Aluminum exposure in food and water can pose several health risks. Chronic exposure may lead to cognitive dysfunction and Alzheimer's disease, although this link is still debated. It can also cause bone disease by leaching calcium, potentially leading to osteomalacia and osteoporosis. In the nervous system, aluminum can cause neurotoxicity, leading to symptoms like memory loss and impaired learning. Additionally, aluminum may accumulate in the brain, potentially contributing to neurodegenerative conditions. It's important to note that the extent of these risks can vary based on individual susceptibility and the level of exposure.</p>

- Q: This question asks for examples of industrial processes that incorporate the use of aluminum.

- <p>Aluminum is widely used in various industrial processes due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Some key industrial processes that utilize aluminum include the automotive industry for manufacturing car parts, the aerospace industry for aircraft construction, the construction industry for building materials, the packaging industry for food and beverage cans, and the electronics industry for components in devices. Aluminum is also used in the manufacturing of machinery, electrical equipment, and transportation equipment. Its versatility makes it a crucial material in many industrial applications.</p>

- Q: This question asks about the reactivity of aluminum with various substances, including its chemical reactions and properties.

- <p>Aluminum is a highly reactive metal that readily reacts with oxygen to form a protective layer of aluminum oxide on its surface. It can also react with acids, such as hydrochloric or sulfuric acid, to produce hydrogen gas and aluminum salts. In the presence of a strong base, aluminum can react to form aluminates and hydrogen gas. Additionally, aluminum can reduce certain metal oxides, such as iron oxide, in a thermite reaction. However, due to its reactivity, aluminum is often used in alloys with other metals to improve its strength and corrosion resistance.</p>

- Q: Is it possible to use aluminum as a material for battery production?

- <p>Yes, aluminum can be used to make batteries. Aluminum-air batteries are a type of metal-air battery where aluminum serves as the anode and undergoes oxidation. These batteries have a high energy density and are environmentally friendly, as they produce minimal waste. However, they face challenges such as water sensitivity and the need for alkaline electrolytes, which limit their practical applications. Research is ongoing to improve their performance and make them more viable for widespread use.</p>

- Q: This question asks for a brief overview of the characteristics or qualities of aluminum nitride, a chemical compound.

- <p>Aluminum nitride (AlN) is a covalent, ceramic material known for its exceptional properties. It has a high thermal conductivity, which is about two-thirds that of copper, making it useful in electronics for heat dissipation. It's also an electrical insulator, exhibiting high electrical resistivity. Aluminum nitride is characterized by its high thermal stability, resistance to thermal shock, and excellent mechanical strength. It's chemically inert, resistant to most acids and alkalis, and has a high melting point of approximately 2200掳C. These properties make it suitable for applications in high-temperature electronics, as a substrate for semiconductor devices, and in the automotive industry for heat sinks and other heat management components.</p>

- Q: This question asks for the specific temperature at which aluminum oxide transitions from a solid to a liquid state.

- <p>The melting point of aluminum oxide (Al2O3) is approximately 2072掳C (3767.6掳F). It is a high melting point due to the strong ionic bonds between aluminum and oxygen atoms in the crystal structure. This high melting point makes aluminum oxide a common material in high-temperature applications such as refractory materials and abrasives.</p>

Send your message to us

Aluminum EN AW-5005 DC Aluminium Circle for Deep-Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords