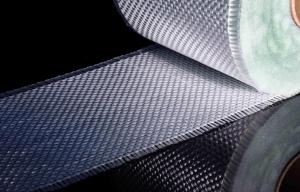

Fiberglass Roving Tape - e-glass fiber woven roving for hand lay-up -1250mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Properties of E-Glass Fiber Woven Roving

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handing easy

Good moldability, fast and complete wet in resins, resulting in high productivity

Good transparency and high strength of composite products

Glass fiber woven rovings are bidirectional fabric made by interweaving direct rovings and compatible with many resin like UP, vinyl ester, epoxy and phenolic resin.

It is a high-performance reinforcement widely used in hand lay-up and robot processes for the production of boats, vessels, plane and automotive parts, furniture and sports facilities

Package of E-Glass Fiber Woven Roving

Woven roving are wounded onto a paper tube which has an inside diameter of 89mm, and the roll has a diameter of 260mm. The roll is wrapped up with plastic film, and then packed in a cardboard box or wrapped up with kraft paper. The rolls are to be horizontally placed. For transporation the rolls can be loaded into a container directly or on pallets.

TDS of E-Glass Fiber Woven Roving

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respectively.

Products Specifications:

| Product code | Mass(g/m²) | Fabric density(end/cm) | Width (mm) | Roll weight(kg) | Compatible resins | |

| warp | weft | |||||

| EWR400 | 400 | 3.6 | 3.2 | 1500 | 40 | UP/EP/VE |

| EWR400 | 400 | 3.6 | 3.2 | 1500 | 50 | UP/EP/VE |

| EWR600 | 600 | 2.6 | 2.4 | 1500 | 40 | UP/EP/VE |

| EWR600 | 600 | 2.6 | 2.4 | 1500 | 50 | UP/EP/VE |

| EWR800 | 800 | 1.8 | 1.5 | 1500 | 40 | UP/EP/VE |

| EWR800 | 800 | 1.8 | 1.5 | 1500 | 50 | UP/EP/VE |

Images:

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

1 *40HQ each day.

- Q: Can glass fiber be used for cement components

- Glass fiber is used as reinforced component is good. It features with weather resistance, acidproof and alkali resistant.

- Q: What can fiber concrete do?

- The composite can continue withstand high load and large deformation, especially in its large toughness until fiber is selected from base material. Compared with ordinary concrete, it can be used to limit the expansion of cracks in the concrete base under the action of external forces. The tensile ultimate strength can be increased by 30 ~ 50%. The fiber reinforced concrete mainly uses short fiber which has a certain length to diameter ratio (i.e., the ratio of the length to the diameter of the fiber). In the design and use of fiber concrete, please refer to the current "technical specification for fiber reinforced concrete structure" if the volume content of the fiber is greater than a critical value, when the ingredients are suitable and suitable for high efficiency water reducing agent. The main function of fiber in fiber concrete. The fiber is the acceptance of the main external force. The fiber products (such as glass fiber mesh cloth, fiber reinforced concrete has high tensile strength and ultimate bending strength., cement-based material and fiber to bear when the external base material occurred after cracking, initial bending). But sometimes we often use long fiber (such as glass fiber roving.

- Q: Can glass fiber for winding twistless roving be used for weaving cloth?

- Yes, twistless roving are used as warp and weft directional material for twistless roving cloth.

- Q: The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q: What are the advantages of the glass?reinforced?plastics antenna? What is the difference between an ordinary antenna and a glass?reinforced?plastics antenna?

- waterproof. structure of the antenna is different from the conventional vertical antenna, but the principle is the same. They all are sealed.

- Q: What does glass fiber operating tools do ?

- wire drawing,drying, winding, fabric and so on.

- Q: What does fireproof bag used for ?

- It is made from cotton.

- Q: The use of glass fiber cloth

- Reinforced material:

- Q: The difference among organic glass, glass steel and acrylic.

- It is composed of methyl methacrylate monomer (MMA) polymerization, having the same life of the building. After a special process, the two kinds of composite organic glass acrylic (acrylic) can be compound, with the English name Acrylic. The extrusion can better control the thickness of the plate.

- Q: Production process of glass fiber tube

- The tube is made in continuous movement of mandrel. It should be feed into steel mould fixed in bearing. After continuous filament winding and centrifugal casting process finishes,the number of pipe manufacturers using reciprocating fiber winding process is more than that of other two production technology. After the resin in products has been solidified, you should inject unsaturated resin with catalyst at the one side of steel mould. This process is that pipe passes through a feeding station whcih aims to supply resin presoak twistless roving. There are mainly three manufacturing techniques of glass fiber pipe. Reciprocating fiber winding technology (belonging to the fixed length method). The main material includes glass fiber reinforced materials and sand. Auxiliary angle (wingding angel) is controlled by the ratio of impregnating vessel movement speed and mandrel rotate speed. Pipe usually solidifies under high temperature. With the help of centrifugal force, its applicability is very good. Continuous filament winding process(belongs to continuous method). Impregnating vessel movement is controlled by computerization machine. With the number of the layers increases gradually, inner tube form a smooth plane due to the centrifugal force and mandrel gets out of glass?reinforced?plastics pipe. Centrifugal casting process (belonging to the fixed length method). Tube made in this way, is also known as glass fiber reinforced plastic sand pipe. Reciprocating filament winding process In this process

Send your message to us

Fiberglass Roving Tape - e-glass fiber woven roving for hand lay-up -1250mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords