duplex seamless pipe 32760

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

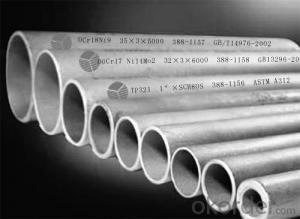

ASTM A789 S32760 Super Duplex stainless steel pipe

1. Good general corrosion resistance

2. Excellent strength and toughness

ASTM A789 S32760 Super Duplex stainless steel pipe

Standard : ASTM A789 A790

Material : S31803;S32205;S32750;S32760

Thickness : 0.8-30mm

OD: 10-710mm

ASTM | UNS | C | Si | Mn | P | S | Cr | Ni | Mo | N | Other |

| S31803 | 0.03 | 1.00 | 2.00 | 0.03 | 0.02 | 21-23 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 |

|

2205 | S32205 | 0.03 | 1.00 | 2.00 | 0.03 | 0.02 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 |

|

2507 | S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24-26 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 | Cu<0.5 |

Zeron 100 | S32760 | 0.03 | 1.00 | 1.00 | 0.03 | 0.01 | 24-26 | 6.0-8.0 | 3.0-4.0 | 0.2-0.3 |

|

Grade | Tensile strength | Yield srength | Elongation | Hardness | |

ASTM | UNS | (Mpa) | (Mpa) | (%) | (HBW) |

| S31803 | 620 | 450 | 25 | 290 |

2205 | S32205 | 655 | 485 | 25 | 290 |

2507 | S32750 | 800 | 550 | 15 | 300 |

Zeron 100 | S32760 | 750 | 550 | 25 | 300 |

- Q: Can stainless steel pipes be used for swimming pool systems?

- Indeed, swimming pool systems can utilize stainless steel pipes. The reason why stainless steel is a favored option for swimming pool piping lies in its remarkable ability to resist corrosion and its durability. It is impervious to rust and can endure exposure to chlorine, saltwater, and other chemicals frequently employed in pool systems. Moreover, stainless steel pipes possess considerable strength, rendering them apt for managing the pressure and water flow within swimming pool systems. Furthermore, stainless steel pipes are simple to clean and maintain, guaranteeing a prolonged lifespan for the pool system.

- Q: Are stainless steel pipes suitable for fertilizer industries?

- Yes, stainless steel pipes are suitable for fertilizer industries. Stainless steel is highly resistant to corrosion, which is essential in an environment where fertilizers and other chemicals are present. Additionally, stainless steel pipes have high strength and durability, making them capable of withstanding the harsh conditions and pressures found in fertilizer production and handling processes.

- Q: Can stainless steel pipes be magnetized?

- Yes, stainless steel pipes can be magnetized if they contain a sufficient amount of ferromagnetic elements, such as iron, nickel, or cobalt. However, most stainless steel pipes are non-magnetic due to the low iron content in their composition.

- Q: What are the weld sleeves for stainless steel pipes?

- Stainless steel pipe is a kind of hollow long strip round steel, mainly used in petroleum, chemical, medical, food, light industry, machinery, instrument and other industrial pipeline and mechanical structure parts. In addition, the bending and torsional strength of the same weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: Are stainless steel pipes fire-resistant?

- Yes, stainless steel pipes are fire-resistant. Stainless steel is known for its high melting point and excellent resistance to fire. It does not readily ignite or contribute to the spread of fire, making it a safe material for various applications, including pipes. Stainless steel pipes can withstand high temperatures without significant deformation or structural damage, providing an added level of safety in fire-prone environments.

- Q: Can stainless steel pipes be used for underground irrigation systems?

- Underground irrigation systems can indeed utilize stainless steel pipes. This material, known for its durability and resistance to corrosion, proves apt for instances where the pipes come into contact with moisture and soil conditions. Due to its ability to withstand high pressure and temperature variations, stainless steel stands as a favored option for underground irrigation systems. Furthermore, its extended lifespan surpasses that of alternative materials, thereby diminishing the necessity for frequent repairs or replacements. Nevertheless, it remains crucial to guarantee proper installation and insulation of the pipes to avert potential damage caused by soil movement or external factors.

- Q: Can stainless steel pipes be sandblasted?

- Stainless steel pipes are capable of undergoing sandblasting, which is a widely utilized technique for cleansing, smoothing, or adding texture to the surfaces of various materials, including stainless steel. This method involves expelling fine particles or abrasive substances at high velocities to eliminate impurities or achieve a desired appearance. By means of sandblasting, it is possible to effectively eliminate rust, scale, paint, or other coatings from stainless steel pipes, thereby preparing them for subsequent treatments such as painting or coating. In order to prevent any damage to the stainless steel surface, it is crucial to carefully consider the type and size of abrasive material employed during the sandblasting process. Furthermore, it is essential to adhere to appropriate safety precautions to ensure the protection of workers from the potential hazards associated with sandblasting.

- Q: What's the difference between cold drawn steel tube and hot rolled steel tube?

- Cold drawn steel tube is a kind of precision cold drawn seamless pipe used for mechanical structure and hydraulic equipment with high dimensional accuracy and good surface finish. The use of precision seamless tube manufacturing machinery structure or hydraulic equipment, etc., can greatly save the working hours of mechanical processing, improve material utilization, at the same time help improve product quality.

- Q: How are stainless steel pipes measured?

- Stainless steel pipes are typically measured using two main dimensions: the outer diameter (OD) and the wall thickness (WT). The OD represents the overall size of the pipe, while the WT indicates the thickness of the pipe's walls. These measurements are crucial in determining the suitability of a stainless steel pipe for specific applications and ensuring compatibility with fittings and connections.

- Q: What are the connecting methods of stainless steel pipes for indoor water pipes?

- Card convex features: easy installation, the connection is not deformed inside and outside, belong to live connection, easy maintenance. Scope of application: cold water system, pipe direct drinking water system, water treatment equipment system. The installation is more suitable, mainly taking into account the replacement of the sealing ring later, the hot water system should be avoided as far as possible. The advantage of the connection is that the installation is simple, convenient and easy to maintain, and the sealing ring in the pipe needs replacing when aging, and the utility model is relatively simple and convenient, and the nut can be replaced as long as the nut is unscrewed. The disadvantage is that the applicable situation is single, in the hot water system sealing ring aging is more prominent, higher cost. Concealed piping and hot water systems are generally not recommended.

Send your message to us

duplex seamless pipe 32760

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords