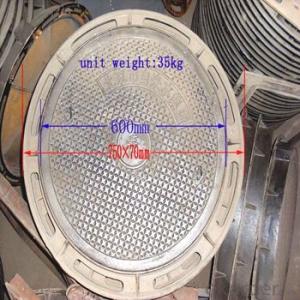

Ductile or Cast Iron Manhole Cover of Standard Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 3500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1) Designs: based on EN124 standard and according to customer's drawing or

samples.

2) Applications: water supply and drainage, fire engineering, natural

3) Inspection: in-house or the third party as per customer's request.

Advantages:

Good compressive, bending and impact strength, anti-corrosion, not rust, long service

life (at least 30 years). The quality meets the same kinds cast ion manhole covers but

the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

Packaging & Shipping:

Packaging: Details Pallet with bubble film, Carton or with pallet.

Delivery Detail: 8 days if your order is 20"container.

Specification:

| No. | Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Size(mm) | Unit Weight (kg/set) |

| 1 | PCE300 | C250 | 200×200 | 300×300 | 35 | 8 |

| 2 | PCE400 | C250 | 300×300 | 400×400 | 40 | 22 |

| 3 | PCE500 | C250 | 400×400 | 500×500 | 45 | 26 |

| 4 | PCE550 | C250 | 500×500 | 550×550 | 45 | 30 |

Our Services:

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.

Meanwhile, a number of experienced workers do the strictly Quality control and have

production tracking program.

5. Our price: we are the factory,

we provide the most competitive price with good quality, and

large order quantity will get big support by us!

6. Professional technical support with free charge.

Pictures:

FAQ:

Why imported Composite Manhole cover/Grating fromChina?

1. Very competitive price, it will save you third or even half cost;

2.Good quality, don't worry much about the quality, actually, most of the building

materials you buy from Miami, Dubai ,Italy, South Africa or your local market are

imported from China. So why not buy direct from China. The key point is to find a

reliable supplier who is honest and professional to take care of the quality and

delivery time.

3.Chinahas full range of Manhole covers which Follow En124 for your market, like

A15,B125,C250,D400.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: What are the requirements for casting steel castings?

- 4 thickness, most should be placed above the.5 and try to reduce the number of.6, the sand core should be used in classification of flat surface

- Q: Is the cast steel a casting part?

- Yes, molten steel is poured into the mold and cooled to become a casting. Can also cast iron, cast aluminum, plastic casting.

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- The technical condition or the material column in the title column will tell whether it is a casting drawing or not. However, the need for casting drawings, and some also through machining (car, milling, etc.), this should be part of the process drawings, process drawings are described

- Q: What should I pay attention to when designing a casting structure?

- The basic structure of unit 3 in the design of metal casting casting and its parameters are selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting casting casting; (2) the inner wall of the internal ribs and the thickness of a should be connected the outer wall thickness of 0.6 to 0.7, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage; (3) to prevent generating white grey cast iron, in addition to taking measures in the process, must make the wall thickness is not too thin (some information that cast fillet at the corner of the wall thickness of 15mm or more, with metal casting casting must be in the corner, for Aluminum Alloy, metal casting magnesium alloy castings shall not be less than 3 ~ 4m; (4) because of the metal type and the core that, for To facilitate the extraction of castings and casting out type, slope casting should be suitably large than sand casting metal casting, the general should be 30% ~ 50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction of the metal type the surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal casting type should be given greater inclination.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

Send your message to us

Ductile or Cast Iron Manhole Cover of Standard Size

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 set

- Supply Capability:

- 3500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords