Ductile Iron Pipe Comply with ISO2531/EN545/EN598

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Ductile Iron Pipe Description :

It has high strength & hardnes as steel and better corrosin resistance than steerl and grey iron, I ductile iron pipe is the ideal substute for gray cast iron pipe and common steel pipe. In addition, our DI pipes are produced with good straightness, identical wall thickness, high dimension accuracy, smooth surface finished, remarkable mechanical properties and firmly sticking internal & external coating layer as well. Flexible Push-in joint and rubber gasket are used for more convenient installation of pipelines.

2. Ductile Iron Pipe Main Features:

1. ISO 2531 or EN 545 Standard K9 Class, K7 Class and C Class

2. ISO 9001 Certificate

3. ISO 2531 & EN 545 Certificate

4. WRAS Potable Water Certificate for Cemen Internal Lining

5. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

6. DN80mm - DN2600mm

7. Black Bitumen or Blue Epoxy Coating

8. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

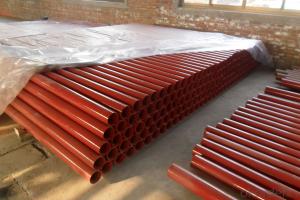

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

1) The standard of pipe: ISO2531:1998, K9

2) Effective length: 6m

3) Inner cement line: Portland cement line as per ISO4179

4) Zinc coating: at least 130g/m2 as per ISO8179

5) Bitumen painting: at least 70um as per ISO8179

6) With 100% quantity of NBR ring, or SBR ring, or EPDM ring as per ISO4633

7) DN80mm-800mm

8) High strength, lighter than grey iron, good corrosion resistance, no furring, small flow resistance, easy fixing, long life tome about 100 yeas

9) Checked by automatic inspection equipment

5.FAQ:

• Industry experience over 20 years.

• Management Systems-Internal Software

• Finished Product Inventory-More Than 5000 Tons.

• Raw Material inventory -Over 8000 Mertic Tons.

• The most convenient transport and prompt delivery.

• Competitive price with best service .

• High technical production line with top quality products.

• High reputation based on best quality products.

- Q: Can ductile iron pipes be used for trench crossings?

- Yes, ductile iron pipes can be used for trench crossings. Ductile iron pipes are known for their high strength and durability, making them suitable for a wide range of applications including trench crossings. They have the ability to withstand heavy loads and external pressures, making them an ideal choice for underground installations. Additionally, ductile iron pipes have excellent corrosion resistance properties, ensuring their longevity and reliability in trench crossing scenarios.

- Q: Are ductile iron pipes resistant to alkaline attacks?

- Generally, ductile iron pipes have resistance against alkaline attacks. Ductile iron is renowned for its durability and ability to resist corrosion, making it suitable for a range of applications, including water and wastewater systems. Certain metals can experience corrosion from alkaline substances, such as high pH levels in water or chemicals. However, ductile iron has been specially engineered to withstand these conditions. Its composition, which includes the addition of alloying elements like nickel and chromium, enhances its resistance to alkaline attacks. Moreover, ductile iron pipes are frequently coated with protective substances like cement mortar or polyethylene, which further increase their resistance against alkaline substances. Nevertheless, it is important to consider that the specific resistance of ductile iron pipes to alkaline attacks can be influenced by various factors, such as the concentration and duration of exposure to alkaline substances, as well as the presence of other corrosive agents. Therefore, it is always advisable to consult with manufacturers or industry experts to ensure the appropriateness of ductile iron pipes for specific alkaline environments.

- Q: How does ductile iron pipe resist internal corrosion?

- Ductile iron pipe resists internal corrosion through a combination of its unique material properties and protective coatings. Firstly, ductile iron, also known as nodular cast iron, is made by adding magnesium to molten iron, which causes the graphite in the material to be nodular or spherical in shape. This results in a more flexible and elastic material compared to traditional cast iron, making it less prone to cracking or fracturing under stress. Additionally, ductile iron has a dense, microstructure with a high carbon content, which acts as a barrier to prevent corrosive elements from penetrating the pipe's surface. This inherent resistance to corrosion makes ductile iron pipe suitable for carrying various fluids such as water, sewage, and chemicals without the risk of degradation over time. Furthermore, ductile iron pipes are often internally lined with protective coatings to further enhance their resistance to corrosion. These coatings, such as cement mortar or epoxy, create a barrier between the pipe's surface and the fluid it carries, preventing direct contact and reducing the likelihood of corrosion. These linings are applied during the manufacturing process, ensuring a consistent and durable protection throughout the entire length of the pipe. In summary, ductile iron pipe resists internal corrosion due to its material composition, including the nodular graphite structure and high carbon content, as well as the application of protective coatings. This combination of factors ensures the longevity and reliability of ductile iron pipes in various applications, even in corrosive environments.

- Q: What is the average diameter range of ductile iron pipes?

- The average diameter range of ductile iron pipes is typically between 3 inches to 64 inches.

- Q: Why does the construction wastewater system use ductile iron pipes instead of galvanized steel tubes?

- Then answer your question: first, the strength of ductile iron is much higher than that of ordinary low carbon steel, such as Q235. Corrosion resistance is much higher than that of ordinary steel pipe and the cost is lower than that of ordinary steel pipe. Second, large diameter steel pipe can only be made of spiral welded pipe, seamless steel pipe is particularly expensive, will not be used. The welded pipe is welded, easy to corrosion water leakage. Third, galvanizing is also a life and very expensive, the pipe has a fluid will wear on the inner wall, zinc plating is meaningless. Galvanized pipe is generally used as a water supply pipe, large caliber water pipes, such as more than 250, and now do not use steel pipes, mostly plastic pipes

- Q: Can ductile iron pipes be used for underground mining applications?

- Yes, ductile iron pipes can be used for underground mining applications. Ductile iron is known for its strength, durability, and resistance to corrosion, making it suitable for underground mining environments where it may be exposed to harsh conditions and abrasive materials. Additionally, ductile iron pipes have excellent load-bearing capabilities, making them ideal for carrying and transporting materials in mining operations.

- Q: What do ductile iron pipes need to connect with three? Can I contact it directly?

- Because the interface material used in the old process is poisonous, especially in the water supply pipeline, environmental protection requires a new process now

- Q: What are the different lining materials available for ductile iron pipe?

- Some of the different lining materials available for ductile iron pipe include cement mortar lining, polyurethane lining, polyethylene lining, and epoxy lining. These linings help to protect the pipe from corrosion and extend its lifespan.

- Q: Can ductile iron pipe be used for stormwater systems?

- Yes, ductile iron pipe can be used for stormwater systems. Ductile iron pipe is a strong and durable material that is commonly used for various applications, including stormwater systems. It has excellent corrosion resistance, making it suitable for handling stormwater, which often contains debris and chemicals. Ductile iron pipe also has high tensile strength and can withstand heavy loads and pressures, making it a reliable choice for stormwater systems that may experience significant flow rates and occasional surges. Additionally, ductile iron pipe is available in various sizes and configurations, allowing for flexibility and adaptability in designing stormwater systems.

- Q: How long do ductile iron pipes last?

- Ductile iron pipes have a lifespan of about 100 years or even more, making them a highly durable and long-lasting choice for water and sewage systems.

Send your message to us

Ductile Iron Pipe Comply with ISO2531/EN545/EN598

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords