Ductile Iron Pipe ISO2531and EN545 Standards

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 300000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Ductile Iron Pipe Description :

1 |

Type:

| The T-type Joint Pipe (Push-on) |

The K-type Joint Pipe | ||

The Self-Restrained Joint Pipes | ||

2 | Standard: | ISO2531, EN545, EN598, etc |

3 | Size: | DN80~2600mm |

4 | Material: | Ductile Cast Iron GGG50 |

5 | Pressure: | PN10, PN16, PN25,PN40 |

6 | Class: | K9, K8, C25, C30, C40 |

7 | Length: | 6m, cut to 5.7m |

8 | Application: | Water supply project, drainage, sewage, irrigation, water pipeline. |

9 | Certificate: | ISO9001, BV, WRAS, SGS |

10

| Internal Coating: | a). Portland cement mortar lining |

b). Sulphate Resistant cement mortar lining | ||

c). High-Aluminum cement mortar lining | ||

d). Fusion bonded epoxy coating | ||

e). Liquid epoxy painting | ||

f). Black bitumen painting | ||

11 | External Coating: | a). zinc+bitumen(70microns) painting |

b). Fusion bonded epoxy coating | ||

c). Zinc-aluminum alloy +liquid epoxy painting | ||

12 | Packing: | Bundles, in bulk |

Note: The coating can also be accordance with customers' requirements. | ||

2. Ductile Iron Pipe Main Features:

- For potable water supply

- High strength

- Long lifespan

- Good corrosion resistance

- Easy installation

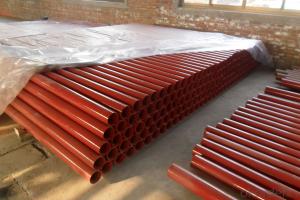

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

1.Standard:ISO2531,EN545,EN598

2.Effective Length:6m/5.7m

3.Internal Lining :Cement mortar, Cement mortar Plus Epoxy

4.External coating:Zinc Primer Plus Bitumen or PE

5. Shipment: By bulk ship or 20'/40' container

6. Rubber: NBR, SBR, EPDM according to ISO4633/EN681.1

7.Quick Delivery

5.FAQ:

Here some questions always been asked

1.For Price CIF CFR FOB CPT and so on both ok for us

2.For Delivery we must try us best to send goods to you asap

3.For Package all standard seaworthy package

4.For Payment, T/T L/C which convenience for you will be ok

- Q: How do ductile iron pipes perform in sandy soil conditions?

- Ductile iron pipes perform well in sandy soil conditions due to their inherent strength and durability. The material's high tensile strength allows it to withstand the pressure exerted by the surrounding soil, preventing pipe deformation and breakage. Additionally, the corrosion resistance of ductile iron ensures a longer lifespan, even in corrosive sandy soil environments.

- Q: The difference between ductile cast iron pipe and machine-made cast iron pipe

- Different appearance, ductile iron pipe single length of 6 meters, large wall thickness; mechanism cast iron pipe single length of 3 meters, the wall thickness is thin.

- Q: How does ductile iron pipe perform in seismic conditions?

- Ductile iron pipe has excellent performance in seismic conditions due to its inherent flexibility and strength. It can withstand ground movements and vibrations caused by earthquakes without fracturing or breaking. Its ability to absorb and dissipate energy helps prevent catastrophic failures and ensures the integrity of the pipeline system. Additionally, ductile iron pipe's corrosion resistance and durability make it a reliable choice for long-term performance in seismic-prone areas.

- Q: How do ductile iron pipes handle water hammer in high-rise buildings?

- Ductile iron pipes are known for their durability and strength, making them an excellent choice for handling water hammer in high-rise buildings. Water hammer is a common phenomenon that occurs when the flow of water in a pipe is suddenly stopped or changed direction, resulting in a pressure surge. This can cause significant stress on the pipes and potentially lead to damage or failure. Ductile iron pipes are designed to withstand high-pressure situations, making them highly resistant to water hammer. They have a high tensile strength and can handle the sudden changes in pressure without deforming or fracturing. This is particularly important in high-rise buildings where the water supply needs to be delivered to various floors with different pressures. Moreover, ductile iron pipes have excellent corrosion resistance properties, which further enhances their ability to handle water hammer. Corrosion can weaken pipes over time and make them more susceptible to failure during pressure surges. However, the corrosion resistance of ductile iron pipes ensures that they remain structurally sound even in high-pressure situations. Additionally, the flexibility of ductile iron pipes allows them to absorb and dissipate the energy generated by water hammer. This helps to minimize the impact on the overall system and reduce the potential for damage. The ability to absorb energy also helps to reduce noise and vibrations associated with water hammer, creating a more comfortable and efficient water supply system. In conclusion, ductile iron pipes are well-equipped to handle water hammer in high-rise buildings. Their strength, corrosion resistance, and flexibility make them a reliable choice for delivering water under varying pressures without compromising the integrity of the system.

- Q: How do ductile iron pipes perform in cold weather conditions?

- Ductile iron pipes are known for their excellent performance in cold weather conditions. Unlike other materials, such as cast iron or PVC, ductile iron has exceptional resistance to low temperatures. This is primarily due to its unique microstructure, which enables it to withstand extreme weather conditions without compromising its structural integrity. In cold weather, ductile iron pipes have a low coefficient of thermal expansion, meaning they do not contract or expand significantly with temperature changes. This characteristic allows them to remain stable and resistant to cracking or bursting, even in freezing temperatures. Additionally, the ductile iron material has high impact resistance, which further enhances its ability to withstand the stress imposed by cold weather conditions. Furthermore, ductile iron pipes have a protective lining, typically made of cement mortar or epoxy, which acts as an additional barrier against the effects of cold weather. This lining prevents the formation of ice on the inner surface of the pipes, reducing the risk of blockages or reduced flow capacity. Overall, ductile iron pipes are a reliable choice for cold weather conditions. Their durability, low thermal expansion, and protective lining make them highly resistant to the challenges posed by freezing temperatures. Whether it is for water supply, sewer systems, or other applications, ductile iron pipes have proven their ability to perform effectively even in the harshest winter climates.

- Q: What is the expected pressure rating for ductile iron pipes?

- The expected pressure rating for ductile iron pipes typically ranges from 150 to 350 psi.

- Q: How much is the working pressure of ductile iron pipe used in water supply pipe and how is MPa determined?

- Upstairs are positive solutions, but now outdoor buried water pipes are using steel wire mesh skeleton, plastic composite pipe instead of ductile iron pipeThe general pressure grades used for water supply pipes are 1.0MPa and 1.6Mpa

- Q: What are the advantages of using ductile iron pipe?

- There are several advantages of using ductile iron pipe. Firstly, it has a high tensile strength, allowing it to withstand high-pressure conditions without deformation or bursting. Secondly, it has excellent corrosion resistance, making it suitable for use in various environments, including underground and underwater applications. Additionally, ductile iron pipe is highly durable and long-lasting, reducing the need for frequent replacements. It is also resistant to fire and has good seismic performance. Lastly, ductile iron pipe offers easy installation and maintenance due to its flexibility and adaptability.

- Q: Can ductile iron pipe be used for water well applications?

- Yes, ductile iron pipe can be used for water well applications. Ductile iron has excellent strength, durability, and corrosion resistance, making it suitable for transporting water in various applications, including water well systems.

- Q: Can ductile iron pipe be used for power plant cooling water systems?

- Yes, ductile iron pipe can be used for power plant cooling water systems. Ductile iron pipe is known for its strength, durability, and corrosion resistance, making it a suitable choice for transporting water in power plant cooling systems. Additionally, its ability to withstand high pressure and temperature variations makes it a reliable option for such applications.

Send your message to us

Ductile Iron Pipe ISO2531and EN545 Standards

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 300000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords