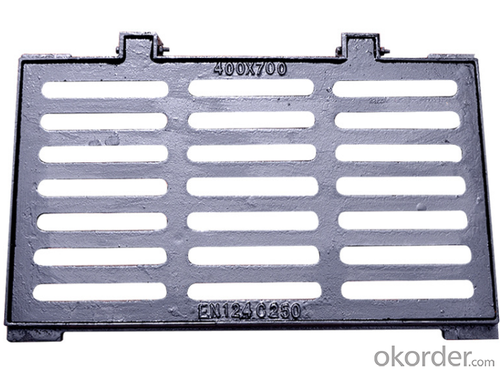

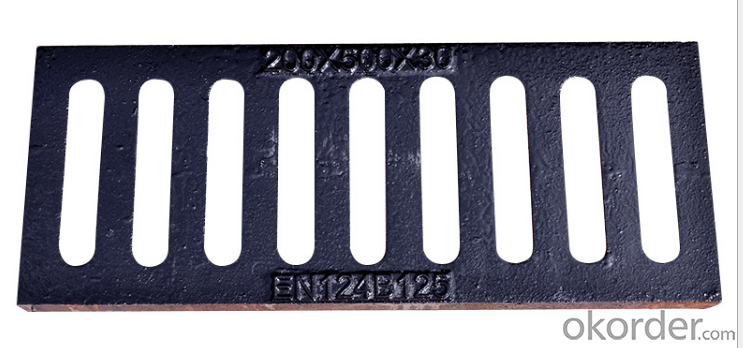

Ductile Iron Manhole Cover with New Styles EN124 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type: round type and Square type, triangle

4) Sand casting

5).we can produce as per customers' drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| D60 | D400 | 500*500 | 600*600 | 100 | 55 |

| D55 | D400 | 450*450 | 550*550 | 100 | 47 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. What is your minimum order requirement?

We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- The pre treatment temperature and the quality of plastic powder are likely to be problems

- Q: The casting sand is going on

- 2, causes(1) sand mold (core) strength is not high, when the box a little reason will fall off.(2) the strength of sand mould (core) is not high, it can not stand the erosion of molten steel.(3) box sand mould (core) crush.(4) high strength under high temperature, warpage, deformation and protuberance into the cast steel under the action of high temperature molten steel.(5) the floating sand in the air hole of the sand mold falls, especially when the floating sand falls in the casting, and the floating sand on the surface of the sand mold is easy to fall through the air vent.(6) when the box is closed, the surface of the mold cavity and the surface of the sand core are not cleaned, and the sand (core) surface has floating sand and so on.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- 1, qualified enterprises will directly iron ore into molten iron, and then poured into the mold, such a good product performance. I work in the cast iron industry, which I can tell you for sure.2, this, like the Great Wall Motor Company has its own parts production department, as well as the corresponding mold center, so it will be their own casting. If the manufacturer does not have these departments, they can only place orders for others to do.

- Q: How to cast iron and wrought iron collocation

- 3, if you have a file in the hand, can be used to file to see finish can also make a judgment from the file down the iron can also be seen, but this is beyond your request, it can be done in the factory. 4, if placed in the grinder grinding, see iron spark from a judge or iron wrought iron, but this is only to do in the factory. About it, may not be full, but through these methods, generally can distinguish between iron or wrought iron.

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

Send your message to us

Ductile Iron Manhole Cover with New Styles EN124 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches