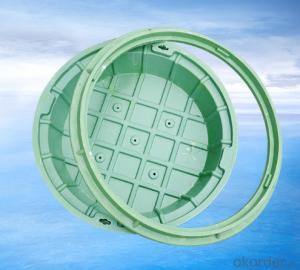

Ductile Iron Manhole Cover C250 with New Style EN124 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type: round type and Square type, triangle

4) Sand casting

5) we can produce as per customers' drawings

6) ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| PCE600 | C250 | 500×500 | 600×600 | 45 | 30 |

| PCE60*80 | C250 | 500×700 | 600×800 | 60 | 45 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 4, the performance requirements of the steel: whether castings or welding parts, there may be quality defects, but the casting will generally be worse than the weldment.You should be able to make a choice in the end.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: What kind of flaw detector is better for casting parts?

- Casting using the detector test, you must first determine the detection process, such as the detection of surface and near surface crack defects, such as casting, recommended by CYD-3000, or CYD-5000 mobile magnetic testing machine for testing.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

- Q: The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

Send your message to us

Ductile Iron Manhole Cover C250 with New Style EN124 Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches