Ductile Iron Manhole Cover with EN124 Heavy Duty

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1.Advantages: Good compressive, bending and impact strenth,anti-corrosion, not rust, long service life

(at least 30 years). The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than. Contain no metal and no recovery value, anti-theft.

2.Applications: water supply and drainage, fire engineering, natural gas,electricity and telecommunications, street lamp and outdoor illuminations.

3.Designs: based on EN124 standard and according to customer's drawing or samples.

4.Color: black, Grey, green, blue and Marble , etc.

5.Inspection: in-house or the third party as per customer's request.

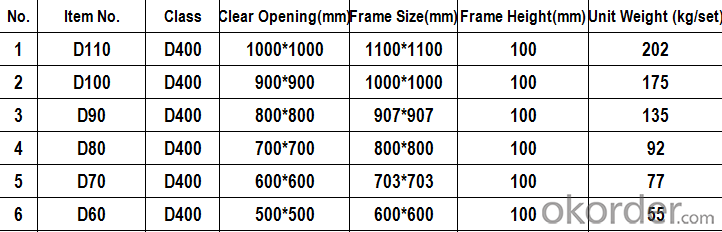

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"containera

Packaging: Details Pallet with bubble film, Carton or with pallet

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

3. Could you specially design and produce for clients?

A: Of course, we have all kinds of professional engineers. We can design and produce special products according to customers' requirements. Such as: special size, special control, OEM, etc.

- Q: What's the effect of casting copper?

- In general cast iron, the mass fraction of copper below 3% - 3.5% can increase the hardness; but when the cast iron has a tendency to chill, or when there is a hard point of free carbides, the addition of copper decreases the hardness.Copper can be used to improve the wear resistance, abrasion resistance, and shock absorption of cast iron, so it is often used in the manufacture of sliding friction iron castings, such as drilling machine spindle, automobile and tractor, valve tappet, etc.. But in white cast iron or chilled cast iron, adding copper does not make any improvement in its abrasion resistance.Copper for certain heat resistant cast iron and austenitic cast iron can increase the heat resistance and corrosion resistance, copper - chromium composite alloy to prevent oxidation under high temperature in the atmosphere from the skin effect is particularly effective, heat resistance and corrosion resistance of austenitic cast iron containing many mass fraction of 4% ~ 7% copper.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Vacuum casting is the process of using ventilation molds. Molten metal flows into the mold by air pressure, and then removes air to form a vacuum. The casting process is mainly used for small parts or jewelry with exquisite detailsCompared with the traditional clay sand casting, heat hardening resin sand casting production with low surface roughness, high precision, good quality characteristics, dimensional accuracy of resin sand mold after hardening with good rigidity and high, and not easy to deform, so in the choice of process parameters, mechanical processing you can select a smaller margin, thereby reducing the consumption of metal solution and machining cost, which can improve the dimensional accuracy of castings.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- This is too muchYou do not have a specific list of statistics, but there are many foundries in china!Moreover, car prices are unlikely to be ordered in the local factories!

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- If is casting, internal shell mold may be not completely dry, strength is not enough, resulting in shell mold collapse into molten steel.It is also possible that the refractory is not refractory enough.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

Send your message to us

Ductile Iron Manhole Cover with EN124 Heavy Duty

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches