Ductile iron manhole cover telecom manhole cover

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description: |

Manhole cover is a removable plate forming the lid over the opening of a manhole, to prevent anyone or anything from falling in, and to keep out unauthoriz

-ed persons and material.

We produce various classes of manhole cover and gratings in gray iron or ductile iron from Class A15

to F900 according to customer's sample or requirm

-ent.

Material | Ductile iron |

Surface Treatment | Painting |

Load | 15 125 250 400 600 900 |

Standard | EN124-2015 EN1433 |

Feature | Easy to install noise reduction |

1. High load strength

Less noise and lower vibration transmissions.

2. Against theft,noise and rust.

3. Durable life.

4. Free design

Class A15 Area which can only be used by pedestrians and pedal cyclists

Class B125 Folkways, pedestrian areas and comparable areas, car parks or parking decks

Class C250 For gratings installed in the area of kerbside channels of roads which, when measured from the Serb edge, extend maximum 0.5 m into the carriageway and maximum 0.2 m into the foot way

Class D400 Arrive ways of roads (pedestrian streets included), hard shoulders and parking areas for all types of road vehicles.

Class E600 Areas subject to high axle loads such as docks and airports

Class F900 Areas subject to very high axle loads such as airports

| Item | Waterproof square 60x60 ductile iron manhole cover |

| Brand name | Better United Casting |

| Size | 200mm-1000mm |

| Type: | Round,square |

| Material | Gray Iron, Ductile Iron, Malleable iron |

| Coating | Cold applied black bitumen Antirust oil, Plating, Paint, Powder Coating, epoxy coating or as per customers' requirement. |

| Application | Municipal construction |

| Loading pressure | EN124 A15,B125,C250,D400,E600,F900, or as per customers' drawings or samples. |

| Advantages | Anti-noise ,Anti-theft,anti-rust,long life service. |

| Package | Pallet and wooden case,or as per customers’ requirements |

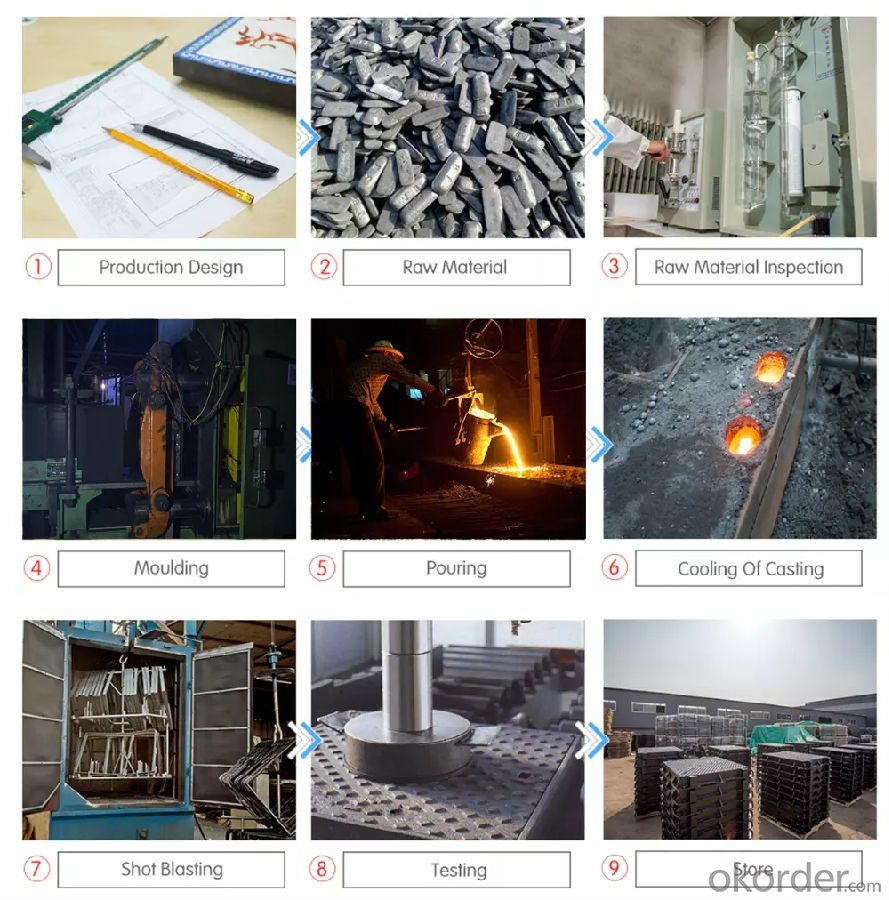

Production Flow:

Packing & Delivery

Packing Details:Plywood pallet; steel pallet; as per custom request

Delivery Time:Different amount of time will be required for different

Fastlead time: Tooling capability 7days ; Sample making 7days

Our Service:

We produce various classes of manhole cover and gratings in gray iron or ductile iron from Class A15 to F900 according to customer's sample or requirments.

OEM&ODM service.

We can design the new 2D or 3D drafts in 2 hours.

All kinds and specifications of equipment, strong production capacity, whether it is manual or mechanical modeling, whether horizontal or vertical lines, regardless of size, demand, we can all meet.

Fast lead time: one week for the mold, one week for the sample, one month for the delivery, time-saving and super valued is our ultimate goal.

Quality System.

With global valued customers.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: What should I pay attention to when designing a casting structure?

- The basic structure of unit 3 in the design of metal casting casting and its parameters are selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting casting casting; (2) the inner wall of the internal ribs and the thickness of a should be connected the outer wall thickness of 0.6 to 0.7, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage; (3) to prevent generating white grey cast iron, in addition to taking measures in the process, must make the wall thickness is not too thin (some information that cast fillet at the corner of the wall thickness of 15mm or more, with metal casting casting must be in the corner, for Aluminum Alloy, metal casting magnesium alloy castings shall not be less than 3 ~ 4m; (4) because of the metal type and the core that, for To facilitate the extraction of castings and casting out type, slope casting should be suitably large than sand casting metal casting, the general should be 30% ~ 50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction of the metal type the surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal casting type should be given greater inclination.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 2, heat aging (artificial aging), also known as stress annealing, is to heat the casting to 550-650 degrees, insulation 2 - 4h, with the furnace cooling to 150 - 200T, and then baked.

- Q: Why should pig iron be used in casting?

- Cast iron is generally called pig iron, but casting is not merely iron casting.For example, injection molding, die casting, and so on, in fact, cast iron, cast steel, cast aluminum, plastic and so on, can be used in the form of casting processing molding

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

- Q: ZGMn13 casting parts processing, with what knife head good?

- its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

Send your message to us

Ductile iron manhole cover telecom manhole cover

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords