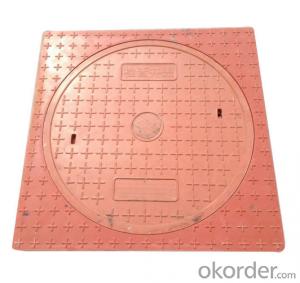

Ductile Iron Manhole Cover for D400 C250 Mining's Systerm with OEM Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

product name: ductile iron manhole cover

1. material: cast iron, ductile iron, malleable iron

2. duty: EN124 A15 B125 C250 D400 E600 F900

3. color: black green gray and etc.

4. design: we can provide OEM service, according your design to do moulds, surface and logo.

5. application: expressway, sidewalk, park, garden, municipal pipeline, telecommunication, water and electrical power projects.

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than.

Contain no metal and no recovery value, anti-theft.

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"container

Packaging: Details Pallet with bubble film, Carton or with pallet

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

FAQ

About Sample

Q : Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

About Customer Logo

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: What is the difference between casting and stamping parts?

- Cold stamping is generally no longer done by cutting, or only a small amount of cutting is required. The precision and surface state of hot stamping parts are lower than those of cold stamping parts, but they are better than those of castings and forgings, and the amount of cutting is less.Stamping is mainly based on process classification, can be divided into separation process and forming process two major categories.

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine, according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: What kind of flaw detector is better for casting parts?

- Casting using the detector test, you must first determine the detection process, such as the detection of surface and near surface crack defects, such as casting, recommended by CYD-3000, or CYD-5000 mobile magnetic testing machine for testing.

- Q: Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

Send your message to us

Ductile Iron Manhole Cover for D400 C250 Mining's Systerm with OEM Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches