Ductile Iron Manhole Cover C250 for Mining and Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Advantages:

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Applications:

water supply and drainage, fire engineering, natural gas,electricity and telecommunications, street lamp and outdoor illuminations.

Designs:

based on EN124 standard and according to customer's drawing or samples.

Color: black, Grey, green, blue and Marble , etc.

Inspection: in-house or the third party as per customer's request.

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"container

Packaging: Details Pallet with bubble film, Carton or with pallet

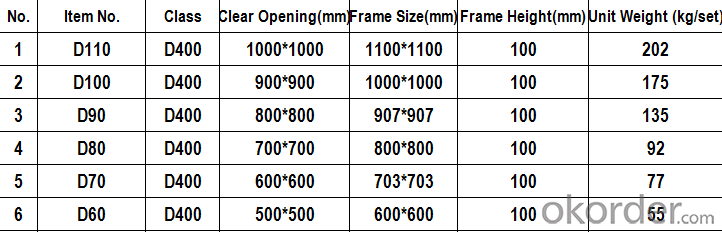

Specifications

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

FAQ

About Sample

Q : Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

About Package

Q: Can I change your package Way?

A: Yes, we can make the form of the package and transportation according to your request, but if any additional charge occurs, you have to pay for it.

About Customer Logo

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- I am doing this for sale, if the price is mainly based on the product structure, the difficulty of pricing. At present, if it is more formal and material guarantee manufacturers generally in 48-53 yuan /Kg (of course, products have a certain weight, such as greater than 100g), our company's current price of about 53 yuan /Kg or so. .

- Q: What are the requirements for casting steel castings?

- 4 thickness, most should be placed above the.5 and try to reduce the number of.6, the sand core should be used in classification of flat surface

- Q: Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- The first to ask, such as casting end cover, bed and other products, is to put the iron melting and casting againThe two question, their casting castings manufacturers than to buy professional casting factory production, production quality more security professional.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold

- Q: What's the cause of the choking of the casting?,

- 3. when casting the environment is humid, sand mold has not removed the moisture, when the casting, the moisture instantaneous transforms into the steam, causes the blowhole

- Q: How can the casting be free of trachoma?

- Measures for the prevention of trachoma in castings:1, sand compaction to high, paint two times;

Send your message to us

Ductile Iron Manhole Cover C250 for Mining and Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 4100 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches