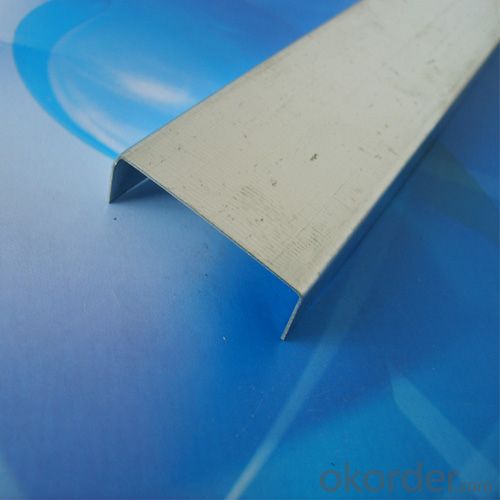

Drywall Partition Light Steel Profiles Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

Specification

commodity | size (mm) | thickness (mm) | length (mm) | pack |

Australia system | ||||

Primary cross rail | 25*21 | 0.55, 0.75,0.85,1.0 | 3600, 4800 | 10 |

Furring channel | 28*38 | 0.55, 0.75,0.85,1.0 | 3000,3600,4800 | 25 |

Wall track | 26*16*26 | 0.45,0.55,0.75 | 3000 | 20 |

Angle | 30*30 | 0.55, 0.75 | 3000 | 50 |

Stud | 51*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 |

64*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

76*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

92*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

Track | 51*32/50 | 0.55, 0.75 | 3000 | 10 |

64*32/50 | 0.55, 0.75 | 3000 | 10 | |

76*32/50 | 0.55, 0.75 | 3000 | 10 | |

92*32/50 | 0.55, 0.75 | 3000 | 10 | |

Middle East system | ||||

Main channel | 38*12 | 0.45,0.50,0.60,0.80,1.0 | 2400,2950,3600 | 20 |

Furring channel | 68*35*12 | 0.40,0.45,0.50,0.60 | 2400,2950,3600 | 25 |

Edge channel | 25*25 | 0.35,0.40,0.45,0.50 | 3000 | 50 |

Stud | 50*34.5 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

70*34.5 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

75*34.5 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*35 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

Track | 52*25 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

72*25 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

76*25 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*25 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

East Europe system | ||||

CD | 60*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 12 |

UD | 28*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 20 |

T-type keel | 20*6 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 |

24*10 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 | |

Stud (CW) | 50*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

70*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*50 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Track (UW) | 52*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

72*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*40 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Product Overviews

- Q: How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q: Shanghai light steel keel ceiling, wall quotes

- Depends on the use of good and bad materials. Ordinary ceiling also 30-40, partition 35-45, I was doing this is what the project. Can contact me. Offer

- Q: What is the light steel keel gypsum board partition? What are the characteristics?

- According to the Austrian decoration experience, light steel keel gypsum board wall with simple construction, light, strong, fire-retardant, thermal insulation and other characteristics, the keel sub-vertical keel and horizontal sub-keel, commonly used width of 65,75, Can be fixed with self-tapping screws on the main keel. Keel can be filled with rock wool and other insulation materials.

- Q: 6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- Formal practice, must be done to the top, unless it is not the request, nobody tube project, it may not be the top.

- Q: Light steel keel partition wall door how to do

- On the light rail keel at the door, apply one or two layers (at least one of the two sides of the upper hinge) to the joinery board - to ensure that the weight of the hinge carrying the door firm.

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- These two estimates are problematic, you can use light steel keel cement pressure plate nail steel wire mesh paint, do waterproof post-paste wall tiles, the following also do waterstops

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- Each brand installation and installation methods and characteristics will be different, I will take the Nexu light steel keel brief description of the next.

- Q: Light steel keel wall gypsum board seams how to deal with? Including smallpox

- First with gypsum slit smooth, and then paste the old white leather paste with kraft paper, as long as the joints have to deal with. Better than the kind of gauze belt. My family used

- Q: Light steel keel partition wall construction process is what

- Processes: Bracket, Divider Pillow Pillow (Design Required) Fixed along the top, along the keel fixed Bone keel installation Vertical keel installation door, window frame installation Additional keel installation Support keel, check keel installation Electrical pipe , Installation of the installation of the wall equipment, a cover panel filled with sound insulation material installation, the other side of the panel panels and corners of the treatment of quality inspection.

- Q: Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Are environmentally friendly materials, the state provides the use of materials, but the high cost. There I do not know, I was in Hebei, are generally in our side of the transfer of goods in the past with.

Send your message to us

Drywall Partition Light Steel Profiles Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords