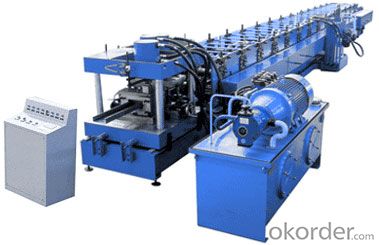

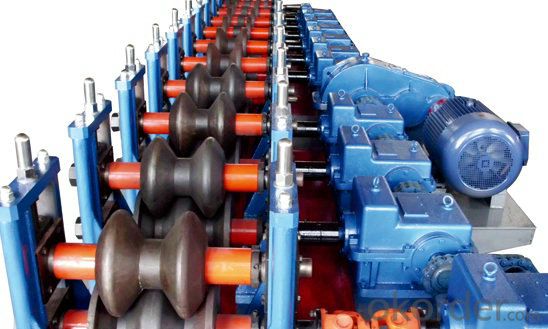

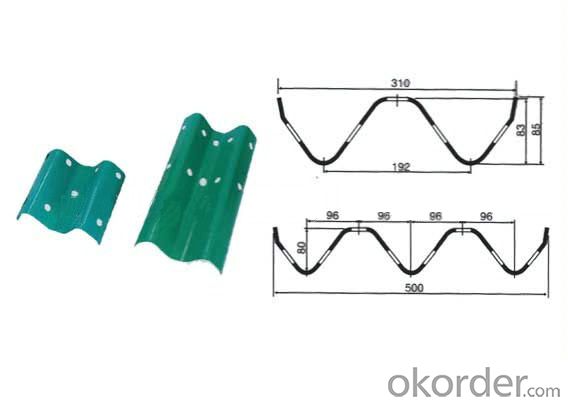

DRAWER GUARDRAIL ROLL FORMING MACHINE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| | |

|

- Q: What are the shortcomings of traditional machining?

- Low efficiency, high cost, batch processing, then the processing quality is not stable, the accuracy is not high, labor intensity, processing staff, frequent processing times, and now good equipment to complete the car, drilling, milling and other processes.

- Q: Information on building materials decoration.

- Building Materials Industry Wallpapers Flooring Pallet Handling Machinery Fireproof Materials Waterproof and Moisture Materials Heat Insulation Materials Pipe Fittings Pipe Fittings Concrete and Products Activities Furniture Manufacturing Machinery Building Materials Processing Building Glass Construction Related

- Q: Information on building materials decoration.

- products special building materials ceiling paint culture stone processing machinery brick, tile and block decoration building materials agent operating reference:

- Q: Classification and components of hydraulic press

- According to the importance of equipment in the production system or application classification, hydraulic equipment can be divided into key equipment, key equipment and general equipment.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- Electrical aspects of more understanding to understand, engage in design to consider more problems, and often a project is not a person can get, need is a technical team.

- Q: Main classification of hydraulic machinery?

- (5) According to the application of equipment, hydraulic equipment can be divided into many types, such as machine tool hydraulic equipment, plastic molding processing hydraulic equipment, engineering machinery hydraulic equipment, steel metallurgy hydraulic equipment, building materials processing hydraulic equipment.

- Q: What gear is machined out of the gear?

- The bevel gears are laid on the planer. Spiral bevel gears - forming end mills.

- Q: What is the principle of the cutting order in machining?

- ④ first rough after the first rough processing, after finishing

- Q: What are the aspects of the mechanical processing quality

- Parts of the processing quality is to ensure that the basis of mechanical product quality. The processing quality of the parts, including the machining accuracy of the parts and the processing of the surface quality, are two major aspects

- Q: What are the oyster processing companies?

- other electronic processing metal processing including | casting pressure processing welding and bonding heat treatment cutting sheet metal processing Electroplating processing CNC and CNC machining line cutting processing other metal processing glass processing ceramic processing rubber processing including rubber rolling processing rubber molding processing rubber post processing processing other rubber processing plastic processing including injection molding extrusion processing blow molding processing plastic processing plastic processing casting Plastic Processing Plastic Surface Treatment Other Plastic Processing Textile Processing Including Spinning Processing Weaving Processing Dyeing & Finishing Quilting Processing Embroidery Processing Hand Knitting Processing Other Textile Processing leather processing entertainment leisure products processing health care products processing business printing processing including brochures

Send your message to us

DRAWER GUARDRAIL ROLL FORMING MACHINE

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords