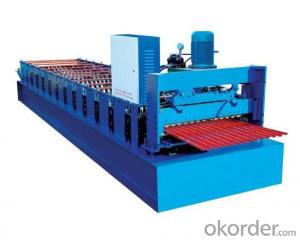

CNC full hydraulic 4 rolls bending machine, full auto 4 roller plate rolling machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

CNC four roller plate rolling machine

1.Hydraulic driven

2.Four driver roller

3.Pre-bending function

4.12 months guarantee

This machine model: HDLW12-four-roller plate bending machine

The movement of each roller of four-roller plate bending machine

1. The top roller makes rotation movement drove by hydraulic motor

2. The down roller makes rotation drove by hydraulic motor as well as making up-down movement drove by hydraulic cylinder.

3. The side rollers make arc swing movement drove by hydraulic oil cylinder.

The advantages of four-roller bending machine

1. hydraulic driven, high efficiency and energy saving (the driving power is only 60% of traditional bending machine)

2. permanent lubricant technology (no refueling within bearing life period)

3. clamping pressure is adjustable (no slipping, and the production efficiency is 50%-80% higher than three roller plate rolling chine

4. The cylinder diameter can achieve 1.1 times of top roller diameter

The four-roller plate bending machine is proper for the following user:

1. The 4 roller plate bending machine will be good choice for the customer who is the first time to use plate bending machine, since the four-roller bending machine is very easy to be operated.

3. The 4 roller plate bending machine will be good choice for the customer who want to have high precision and improve the products quality

4. The 4 roller plate bending machine will be good choice for the boss who wants to use only one operator to save labor cost

5. If the steel plate is in the large size or the customer request high throughput or for the sake of safety, the customer needs handling device, feeding table and top & side support device, the four-roller machine will be good choice.

6. The four-roller plate bending machine will be good choice for the boss who wants to use CNC control and so on.

- Q: What are the shortcomings of traditional machining?

- First, the production efficiency is low, the cost, followed by the processing quality is not stable, the third labor intensity, lack of security.

- Q: Information on building materials decoration.

- Building Materials Industry Wallpapers Flooring Pallet Handling Machinery Fireproof Materials Waterproof and Moisture Materials Heat Insulation Materials Pipe Fittings Pipe Fittings Concrete and Products Activities Furniture Manufacturing Machinery Building Materials Processing Building Glass Construction Related

- Q: Information on building materials decoration.

- products special building materials ceiling paint culture stone processing machinery brick, tile and block decoration building materials agent operating reference:

- Q: Classification and components of hydraulic press

- According to the control mode classification According to the control mode, the hydraulic equipment can be divided into electronic control, machine control and manual control three categories.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- To do the theoretical basis of mechanical design is essential, learn a few auxiliary tools, CAD, PRO / E, slidworks are more commonly used.

- Q: Main classification of hydraulic machinery?

- (2) according to the size of the equipment according to the size of equipment, hydraulic equipment can be divided into large equipment, medium-sized equipment, small equipment.

- Q: What gear is machined out of the gear?

- The bevel gears are laid on the planer. Spiral bevel gears - forming end mills.

- Q: What is the principle of the cutting order in machining?

- ③ the first main after the first processing of the main surface, and then processing the secondary surface.

- Q: What are the aspects of the mechanical processing quality

- The so-called machining precision refers to the actual geometric parameters (size, shape and surface of the mutual position between the workpiece) and the ideal geometric parameters of the degree of compliance. The higher the degree of compliance, the higher the machining accuracy.

- Q: What are the oyster processing companies?

- printed posters printing desk calendar printing calendars printing business cards printing envelopes printing paper printing stickers printing other commercial printing processing books printing processing paper processing 2 processing laser plus .. The

Send your message to us

CNC full hydraulic 4 rolls bending machine, full auto 4 roller plate rolling machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords