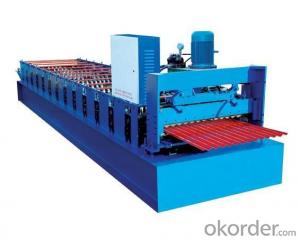

GALVANIZED STEEL ROOF ROLL FORMING MACHINE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

35-205-820 type of glazed tile machine including molding host, hydraulic station, feeding, molding cut, control box, discharge frame. Caigang glazed tile equipment roller die forming of archaize glazed tile with good appearance, of primitive simplicity and elegant, elegant chic modelling, such characteristics as high grade, can be widely used in factories, tourist scenic spot, pavilions, garden hotel, exhibition hall, resort villa, family and other buildings and outdoor decoration. Glazed tile press production line with galvanized steel plate color or different color steel or aluminum as raw materials, production of products used in the roof of the building external plate and wall board and interior decorating plate or, ceiling, etc., increase the roofs or walls of aesthetics, and durability.

| model | 35-205-820 | usage |

| effective width(mm) | 820 | |

| coil width(m) | 1-1.25 | wall/roof plate |

| coil thickness(mm) | 0.5-1.5 | |

| groove distance(mm) | 205 |

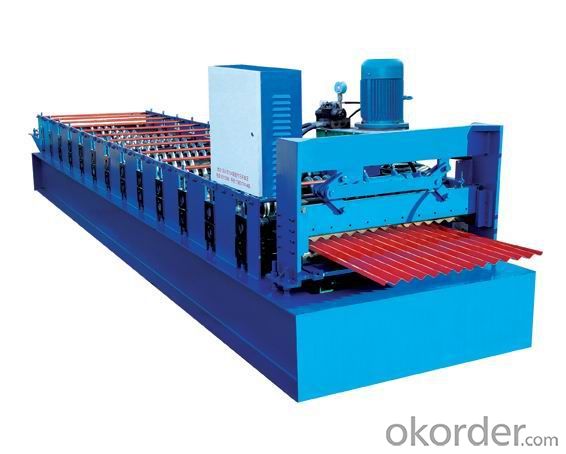

Corrugated panel roll forming machine

Main Teachnical Parameters

1.Material thickness: 0.2-1.0mm

2.Feeding width: 900mm

3.Effective width: 760mm

4.Forming speed: 12-16m/min

5.Diameter of the shaft: 70mm

6.Main power: 4KW

7.Forming steps: 16 steps

8.Material of shaft: 45#steel, quenched and tempered

9.Side board thickness: S18mm

10.Material of Rollers: Bearing steel

11.Driven style: by chain

12.Control system: Panasonic PLC

13.Hydraulic cutting part

i.Power: 3 KW

Material of cutter: Cr12, quenched

- Q: What are the shortcomings of traditional machining?

- Low efficiency, high cost, batch processing, then the processing quality is not stable, the accuracy is not high, labor intensity, processing staff, frequent processing times, and now good equipment to complete the car, drilling, milling and other processes.

- Q: Information on building materials decoration.

- Equipment Construction Projects Cooperation Adhesives Metal Building Materials Insulation Materials Building Materials Door and Window Wall Materials Wood Sheet Other Building Materials Products Construction Materials Stone Stone Lime, Gypsum Plastic Building Materials Locks Ceramic Processing Machinery

- Q: Information on building materials decoration.

- products special building materials ceiling paint culture stone processing machinery brick, tile and block decoration building materials agent operating reference:

- Q: Classification and components of hydraulic press

- According to the importance of equipment in the production system or application classification, hydraulic equipment can be divided into key equipment, key equipment and general equipment.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- Can not exchange what ah, I just graduated from a mechanical professional and then a large state-owned enterprises, do machine processing, feeling, too buried no talent, and their own pro-prog have all very skilled, the results should be forgotten, can not give the younger

- Q: Main classification of hydraulic machinery?

- (4) According to the importance of equipment in the production system or application classification, hydraulic equipment can be divided into key equipment, key equipment and general equipment.

- Q: What gear is machined out of the gear?

- The bevel gears are laid on the planer. Spiral bevel gears - forming end mills.

- Q: What is the principle of the cutting order in machining?

- In the arrangement of mechanical cutting process, should be based on the processing stage of the division, the choice of benchmarks and the surface to be processed to decide, generally should follow the following principles:

- Q: What are the aspects of the mechanical processing quality

- Parts of the processing quality is to ensure that the basis of mechanical product quality. The processing quality of the parts, including the machining accuracy of the parts and the processing of the surface quality, are two major aspects

- Q: What are the oyster processing companies?

- printed posters printing desk calendar printing calendars printing business cards printing envelopes printing paper printing stickers printing other commercial printing processing books printing processing paper processing 2 processing laser plus .. The

Send your message to us

GALVANIZED STEEL ROOF ROLL FORMING MACHINE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords