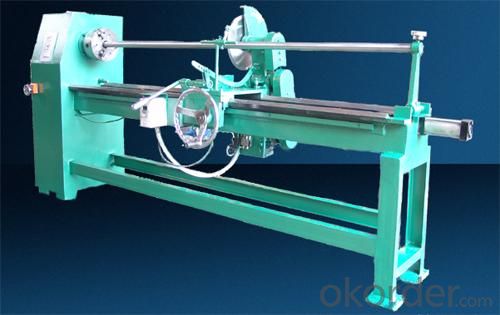

BX-510 High-precision Slitting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Use:

used for rewinding and slitting of various types of non-adhesive material.

Characterisics :

slitting machine

Left and right spindles are adopted to unreel by centre reeling,the reeling and rewinding adopt pneumatic core shaft,rewinding automatic tensity control,reeling manual tensity control.About the differential device adjustment the tensity is balanced.The splitting shall adopt upper and lower rotary blade. Revolves the work table assistance to unload the volume,while adopting digital control drive system and human-machine interface touch data input model.PLC centralism processing.Electric engine is accommodidated by transducer and running steadily.Receives the reel rocking shaft by the hydraulic pressure actuationrotation,the photoelectric control side;guider roller,the sound of something astir is balanced;processing,the cutting bar,quenching and retempering treatment ,the rotary system puts the volume work table,EPC automatically investigates, this machine minute row volume end surface to the smooth ,easy to operate.

Application :

Maximum valid width of material : 1350mm

Maximum valid diameter of material : 500mm

maximum valid rewinding diameter : 700mm

internal diameter of rewinding paper pipe :3"

slitting tool : upper and lower rotary knives

Maximum width of strip : 1350mm

minimum width of strip : 5mm

the precision of stripping : ±0.1mm

motor power : 8.5kw

the speed of striping : 30m/minute

working voltage :380V 50Hz

the precision of border-entangling: ±0.3mm

- Q: What are the shortcomings of traditional machining?

- Machined parts after each done should have a traceability of the unique identification number, the identification number is the identity of the ID card, identification number should have a unified coding rules,

- Q: Information on building materials decoration.

- Products Special Building Materials Ceiling Coatings Culture Stone Bamboo Processing Machinery Brick, Watt and Block Decorative Building Materials Agent

- Q: Information on building materials decoration.

- Materials Insulation Material Stock Building Door & Window Wall materials wood sheet other building materials products construction materials stone stone lime, gypsum plastic building materials locks ceramic processing machinery ceramic enamel

- Q: Classification and components of hydraulic press

- According to the control mode classification According to the control mode, the hydraulic equipment can be divided into electronic control, machine control and manual control three categories.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- Electrical aspects of more understanding to understand, engage in design to consider more problems, and often a project is not a person can get, need is a technical team.

- Q: Main classification of hydraulic machinery?

- (1) according to the control mode by the control mode, hydraulic equipment can be divided into electronic control, machine control and manual control three categories.

- Q: What gear is machined out of the gear?

- Early in the universal milling machine, with the indexing head index, with the shape of the cutting edge and gear groove shape of the same forming disc cutter or milling cutter milling manufacturing.

- Q: What is the principle of the cutting order in machining?

- In the arrangement of mechanical cutting process, should be based on the processing stage of the division, the choice of benchmarks and the surface to be processed to decide, generally should follow the following principles:

- Q: What are the aspects of the mechanical processing quality

- Parts of the processing quality is to ensure that the basis of mechanical product quality. The processing quality of the parts, including the machining accuracy of the parts and the processing of the surface quality, are two major aspects

- Q: What are the oyster processing companies?

- Processing industry is divided into two categories: 1 finished product processing: building materials processing drugs processing sports products processing environmental protection equipment processing energy products processing shoe materials, shoe processing medical equipment processing audio and video products processing instrumentation processing industry special equipment processing hardware tools processing jewelry processing apparel Processing of finished shoes processing spray processing stone processing bamboo processing paper processing electronic processing including | patch processing plug-in processing bonding processing electronic assembly processing welding proc

Send your message to us

BX-510 High-precision Slitting Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords