Double Sided Tissue Tape Water Based Acrylic Sgs&Iso9001 Carrier Tape Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

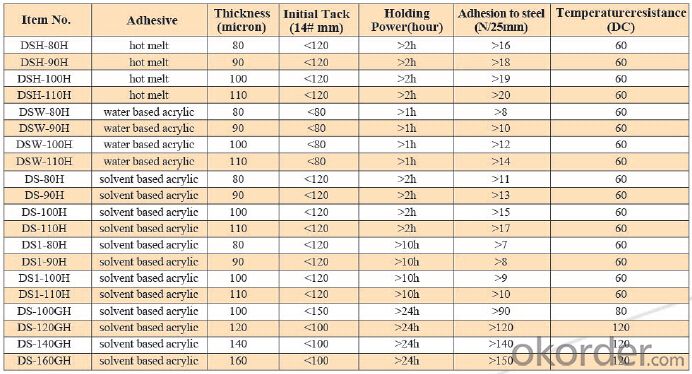

Typical Physical Reports of Double Sided Tissue Tape

Description

The Double Sided Tissue Tape is of tissue as the carrier, coating with hot melt adhesive, water based acrylic, solvent based acrylic. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Double Sided Tissue Tape: widely used for bonding, fixing for leather, foam, sponge, garment, shoe, luggage, plastic, paper splicing and stationery.

Packaging & Delivery

Packaging Detail:

Log Roll: Length 1000mm; width: 1050mm, 1260mm, 1040mm..

Cut Roll: As per customer’s requirements

Delivery Detail: within 7-15 working days after receiving your deposit

Service

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: Is packaging tape resistant to extreme pressure or weight?

- Packaging tape is designed to provide a strong and secure seal for packages, but its resistance to extreme pressure or weight can vary depending on the specific type and quality of the tape. Generally, packaging tapes are made from durable materials like polypropylene or polyester that can withstand typical handling and transportation pressures. However, it is important to note that packaging tape may not be able to withstand extremely heavy loads or excessive pressure. In such cases, it is recommended to reinforce the tape with additional layers or use specialized heavy-duty tapes that are specifically designed for high-pressure or weight-bearing applications.

- Q: How does packaging tape perform on high-friction surfaces?

- Packaging tape is designed to adhere to a wide variety of surfaces, including high-friction surfaces. Its performance on high-friction surfaces can vary depending on the specific tape and the nature of the surface. In general, packaging tape is equipped with strong adhesive properties that allow it to stick securely to surfaces, even those with high friction. The adhesive on the tape is formulated to provide excellent tackiness and bonding strength, ensuring that it stays in place and maintains its hold on high-friction surfaces. However, it is important to note that excessive friction or roughness on a surface can potentially affect the tape's adhesion. If the surface is extremely rough or uneven, it may create air pockets or gaps between the tape and the surface, which can compromise its performance. In such cases, it is advisable to prepare the surface properly by cleaning and smoothing it before applying the tape to ensure optimal adhesion. Additionally, the durability of the tape can play a role in its performance on high-friction surfaces. Some packaging tapes are reinforced with fibers or have a thicker construction, making them more resistant to wear and tear caused by friction. These tapes are often recommended for heavy-duty applications or when packaging items that will be subjected to constant rubbing or sliding on high-friction surfaces. Overall, packaging tape is generally well-suited for use on high-friction surfaces. Its adhesive properties, combined with proper surface preparation and selection of a suitable tape, can ensure reliable and long-lasting adhesion, even in challenging conditions.

- Q: Can packaging tape be used for sealing packages with heavy items?

- Certainly, one can utilize packaging tape to seal packages that contain bulky items. Packaging tape is purposely crafted to offer robust stickiness and sturdiness, thus rendering it ideal for securing packages that carry weighty contents. It is manufactured from resilient materials such as polypropylene or acrylic, guaranteeing its ability to endure the weight and pressure of substantial items without tearing or becoming loose with ease. Furthermore, packaging tape frequently possesses a formidable adhesive backing that adheres well to different surfaces, thus ensuring a reliable seal. Nonetheless, it is imperative to select the fitting width and thickness of packaging tape in order to ensure proper sealing for packages with heavy contents.

- Q: What are the benefits of using colored packaging tape?

- There are several benefits of using colored packaging tape. Firstly, colored packaging tape allows for easy identification and organization of different items or packages. By using different colors for specific products or categories, it becomes much simpler to quickly locate and retrieve the desired items. This can be especially helpful in warehouses or storage facilities with a large volume of goods. Secondly, colored packaging tape can act as a visual indicator or warning. It can be used to highlight fragile or delicate items, ensuring that they are handled with care during shipping or transport. This can help prevent damage and reduce the risk of mishandling. Additionally, colored packaging tape can be used for branding purposes. By using tape in company colors or with a custom design, businesses can enhance their brand visibility and recognition. This can make their packages stand out amongst others and leave a lasting impression on customers. Furthermore, colored packaging tape can also serve as a security measure. Some tapes are tamper-evident, meaning that it leaves a visible mark or shows signs of tampering if someone tries to open the package. This can help protect the contents of the package and provide reassurance to both senders and recipients. Lastly, colored packaging tape can simply add a touch of aesthetics to the packaging. With a wide range of colors and designs available, businesses can choose tape that complements their branding or adds a pop of color to their packaging, making it more visually appealing. In summary, the benefits of using colored packaging tape include easy identification and organization, visual indicators for fragile items, branding opportunities, security measures, and aesthetic enhancements.

- Q: Is packaging tape safe to use on plastic hangers?

- Packaging tape is generally safe for use on plastic hangers, as it is designed to securely hold items together and can adhere well to various surfaces, including plastic. However, it is important to take into account the type of plastic hanger and its intended purpose. While packaging tape may be suitable for temporarily securing clothes on a plastic hanger, it could potentially leave residue or cause damage if left for an extended period. It is recommended to test a small area of the hanger first to ensure that the tape does not cause any harm or leave marks. Moreover, if the plastic hanger is used for displaying or storing delicate or valuable clothing, it might be better to consider gentle alternatives such as fabric-friendly tape or non-adhesive hanger attachments.

- Q: What is packaging tape?

- Packaging tape is a type of adhesive tape specifically designed for sealing and securing packages. It is typically made of a strong and durable material, such as polypropylene or PVC, and is used to hold boxes and cartons together during transportation or storage.

- Q: Does packaging tape come in different colors?

- Yes, packaging tape does come in different colors. While the most common color for packaging tape is clear, there are also a variety of colors available to meet different needs and preferences. Some examples of colored packaging tape include red, blue, green, yellow, and black. These colored tapes can be used for various purposes such as color-coding different packages, indicating priority shipments, or simply adding a pop of color to your packaging. Additionally, colored packaging tape can also be used for decorative or artistic purposes, making it a versatile option for both practical and creative applications.

- Q: Buy adhesive tape every time, discover its sticky viscosity is insufficient, encounter cold weather, do not use well,

- 2, holding power: in the tape completely stick objects, persistent viscous, test method is: the use of specified size of tape surface with live two plates, and a steel plate hanging on the tester, another piece of suspension 1KG weight, see two plates not separated how long can the time.

- Q: Can packaging tape be used for sealing construction or building materials?

- Yes, packaging tape can be used for sealing construction or building materials. While it may not be as durable or strong as specialized construction tapes, packaging tape can still provide a temporary or quick solution for sealing materials such as cardboard, plastic sheets, or lightweight panels. It can be used to secure temporary covers, attach protective layers, or hold materials in place during construction or renovation projects. However, for long-term or heavy-duty applications, it is recommended to use tapes specifically designed for construction purposes, as they are more resistant to weather, UV rays, and have stronger adhesive properties.

- Q: Can packaging tape be used for sealing envelopes?

- Indeed, sealing envelopes can be accomplished with packaging tape. While its primary purpose is to securely seal boxes and packages, packaging tape can also effectively seal envelopes. Its formidable adhesive properties guarantee a sealed envelope throughout its journey. Nonetheless, it is worth mentioning that packaging tape may not be the most visually appealing option for sealing envelopes, as it tends to be wider and less transparent compared to conventional choices like glue sticks or clear tape.

Send your message to us

Double Sided Tissue Tape Water Based Acrylic Sgs&Iso9001 Carrier Tape Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches