Flipkart Branded Double Sided Tissue Tape Hot Melt for Embroidery

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1600 g/m²

- Supply Capability:

- 120000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description

| Production name | Double Sided Tissue Tape Hot Melt For Embroidery |

| Material | Tissue + acrylic adhesive |

| Color | Transluscent |

| Usage | General use double adhesive |

| Feature | ♦ Double Adhesive Tissue Tapes. ♦ Good diecut material. |

| Advantage | 1.Factory supplier:We are a factory professional in making double sided tissue adhesive tapes . 2.Competitive price:Factory direct sales, professional production, quality assurance, 3.Perfect service:Delivery in time,and any question will be replied in 24 hours |

2.Packaging & Delivery

Packaging Details:

Standard Roll: 111L X 20W X 20H (cm) Cartons

1 rolls per carton 11KG / Carton

Slit Roll: 46L X 35WX 36H (cm) CartonsDelivery Detail:

Shipped in 15 days after payment

3.Product Show

Other Related Product:

We also supply Duct tape, Masking tape, Double sided tissue tape, PET tape, Foam tape, PVC tape, Warning tape, Fiberglass tape, Kraft adhesive tape, Aluminum Foil Tape, Foam double side adhesive tape and so on.

4.Company Information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM is a professional adhesive tape supplier engaged in adhesive tape manufacturing , project technical support and adhesive design.

We specilized in Duct tape, Masking tape, Double sided tissue tape, PET tape, Foam tape, PVC tape, Warning tape, Fiberglass tape…Now we have exported our products to over 30 countries and regions like Europe ,South / North America ,Southeast Asia etc and gained customer's respect and continued businesses. Based on our good quality , reasonable price, good after-sale service, we enjoyed good reputation in the international market.

Warmly welcome your any inquiries or request ! You will be impressed by our superior quality, quick delivery date and attractive price. Contact us now!

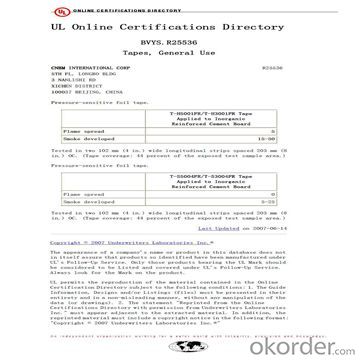

5.Our Certification

Our Factory

6.Our services

1.OEM Service

Your own design is appreciated; we can make the approval sample according to your golden sample.

2. QC Service

a) Before the order to be confirmed, we should check the material & color of fabric by sample which should be strictly.

b) We will be tracing the different phase of production from the beginning.

c) Every bad quality will be checked & cleaned before packing.

d) Before delivery clients could send one QC or point the third party to check the quality.

e) We will try our best to help clients when problem occurred.

3. After-sale Service

a) EXW, FOB, C&F are also available for us.

b) If the products need certificate, we can also provide.

7.FAQ:

Q1: May I have samples?

A: Yes, Free samples available and freight collect by DHL,FEDEX,TNT,UPS,SF,ect.

Q2: Are you manufacturer or trading company?

A: We are professional Manufacturer/factory .

Q3: Can I use our own designing?

A: Yes, size, color, printing, logo, paper core, carton box can be customized.

- Q: Is packaging tape safe to use on plastic picture frames?

- Packaging tape can generally be used on plastic picture frames without any safety concerns. Its design emphasizes strength and durability, making it ideal for securing various items, including plastic frames. However, before using packaging tape on plastic picture frames, it is crucial to take a few factors into account. Firstly, ensure that the tape does not contain any adhesive that could harm the frame or leave behind residue. It is recommended to test a small, inconspicuous area of the frame with the tape before applying it to the entire frame. Additionally, when removing the tape, exercise caution to prevent any potential damage to the frame. Overall, by being cautious and selecting an appropriate tape, packaging tape should pose no safety risks when used on plastic picture frames.

- Q: What are the considerations for using packaging tape on delicate surfaces?

- When using packaging tape on delicate surfaces, there are several considerations to keep in mind. Firstly, it is important to choose the right type of tape. Opt for a tape specifically designed for delicate surfaces, such as low-tack or painter's tape. These tapes are typically less sticky and have a gentler adhesive that won't damage or leave residue on sensitive materials like paper, fabric, or painted surfaces. Secondly, before applying the tape, ensure that the surface is clean and free from any dust, dirt, or moisture. This will prevent any particles or contaminants from getting trapped under the tape and potentially causing damage. When applying the tape, be cautious and gentle. Avoid pressing down too hard or stretching the tape excessively, as this can increase the risk of tearing or damaging the delicate surface. Take your time and carefully smooth out any wrinkles or air bubbles to ensure proper adhesion. Additionally, it is advisable to test the tape on a small, inconspicuous area of the delicate surface before fully committing to using it. This will help you assess its compatibility and whether it causes any adverse effects or damage. Lastly, when removing the tape, do so slowly and carefully. Pull the tape back at a low angle, parallel to the surface, to minimize the risk of tearing or leaving any residue behind. If any residue does remain, use a gentle adhesive remover or warm soapy water to clean the surface. By considering these factors, you can effectively use packaging tape on delicate surfaces without causing any harm or leaving unwanted marks or residue.

- Q: Can packaging tape be used for sealing cloth or fabric items?

- Packaging tape has the capability of sealing cloth or fabric items. Its design ensures strength and adhesive properties, making it efficient for securing and sealing different materials, such as cloth and fabric. When it comes to packages containing cloth or fabric items, packaging tape becomes particularly handy as it ensures a secure closure that prevents any potential damage or loss during transportation or storage. Furthermore, the transparency of packaging tape allows for effortless identification of the contents while maintaining the overall appearance of the cloth or fabric item intact.

- Q: How do I store packaging tape?

- For optimal storage of packaging tape, it is recommended to place it in a cool and dry location, avoiding direct exposure to sunlight. This will maintain the tape's adhesive qualities and prevent it from becoming fragile or losing its stickiness. An ideal option for this purpose would be a plastic storage bin or a cool, dry drawer. Additionally, it is advisable to either keep the tape in its original packaging or employ a tape dispenser to safeguard it against dust and other impurities. By adhering to these storage instructions, you can guarantee that your packaging tape remains in excellent condition and readily available for whenever it is required.

- Q: Can packaging tape be used for sealing plastic tubing?

- Yes, packaging tape can be used for sealing plastic tubing. Packaging tape is designed to provide a strong and secure seal on various surfaces, and it can adhere well to plastic materials. However, it is important to consider the specific application and requirements of the plastic tubing. If the tubing is meant to contain liquids or gases under pressure, or if it requires a more permanent and durable seal, it may be more appropriate to use specialized sealing methods such as heat sealing or using specific types of adhesives designed for plastic materials. Ultimately, the suitability of packaging tape for sealing plastic tubing depends on the specific circumstances and requirements of the application.

- Q: Does packaging tape come in different dispenser options for ease of use?

- Packaging tape is available in different dispenser options, making it easier to use. The market offers various types of dispensers that are specifically designed to simplify the process of sealing boxes or packages. These dispensers come in different sizes, styles, and functionalities to accommodate different needs and preferences. One popular type of dispenser is the handheld dispenser. It is lightweight and compact, making it easy to handle and maneuver. These dispensers usually have a serrated blade for cutting the tape and a comfortable grip for better control. They are ideal for small to medium-sized packaging tasks. For larger packaging jobs, tabletop or benchtop dispensers are available. These dispensers are designed to sit on a surface and securely hold the tape roll in place, allowing for efficient and continuous taping. They often have a built-in cutting mechanism for easy and precise tape cutting. Moreover, there are automatic or electric dispensers that offer even more convenience. With these dispensers, you can effortlessly dispense and cut the tape with the push of a button, saving time and effort. They are especially useful for high-volume or repetitive packaging needs. To summarize, different dispenser options are available for packaging tape to cater to various preferences and requirements. Whether you need a handheld dispenser for small tasks or an automatic dispenser for larger volumes, there are dispenser options that can enhance the ease of use and efficiency of your packaging process.

- Q: Can packaging tape be used for heavy-duty packaging?

- Yes, packaging tape can be used for heavy-duty packaging. There are different types of packaging tapes available in the market, including heavy-duty ones specifically designed to withstand the demands of heavy or bulky packages. These tapes are generally made with durable materials like reinforced fibers or strong adhesives that provide excellent strength and secure packaging. They are capable of holding together heavy and rigid boxes, preventing them from opening or tearing during transit. When choosing packaging tape for heavy-duty packaging, it is important to consider the weight and size of the package, as well as the specific requirements of the shipping or handling process.

- Q: Is packaging tape safe to use on plastic cutting mats?

- Before using packaging tape on plastic cutting mats, it is important to take a few factors into consideration. Firstly, make sure that the cutting mat is made of a durable and food-safe material. Some lower quality mats may get scratched or torn when tape is applied, so it is advisable to check the manufacturer's recommendations. Secondly, think about why you want to use packaging tape on the cutting mat. If it is for temporary storage or transportation, packaging tape can provide a secure seal. However, if the tape will come into direct contact with food or be used during food preparation, it is best to avoid using packaging tape. The adhesive residue from the tape could transfer onto the food or contaminate the cutting surface, which could be a health risk. In such cases, it is better to use food-grade or specialized tape that is specifically designed for cutting mats or food preparation surfaces. In conclusion, although packaging tape can be safe to use on plastic cutting mats, it is crucial to consider the quality of the mat, the purpose of using the tape, and potential food safety concerns. Always prioritize the safety and hygiene of your food preparation surfaces by choosing the appropriate tape.

- Q: How wide is standard packaging tape?

- Standard packaging tape is typically 2 inches wide.

- Q: Can packaging tape be used for sealing packages with perishable items?

- No, packaging tape is not suitable for sealing packages with perishable items as it does not provide the necessary insulation or protection needed to maintain the freshness and quality of such items. It is recommended to use specialized packaging materials such as insulated boxes or coolers along with appropriate sealing methods for perishable items.

Send your message to us

Flipkart Branded Double Sided Tissue Tape Hot Melt for Embroidery

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1600 g/m²

- Supply Capability:

- 120000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords