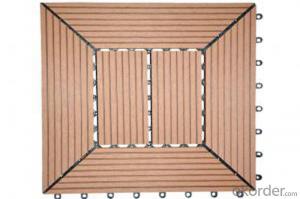

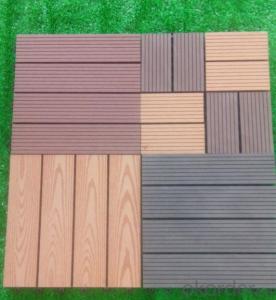

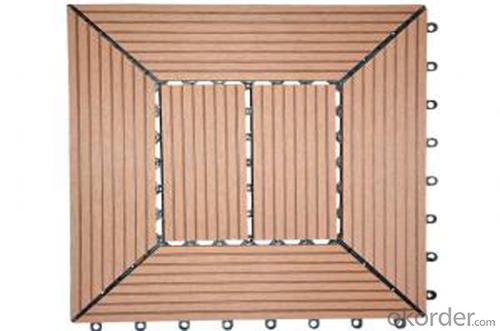

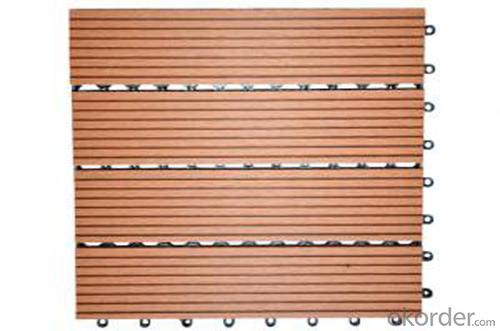

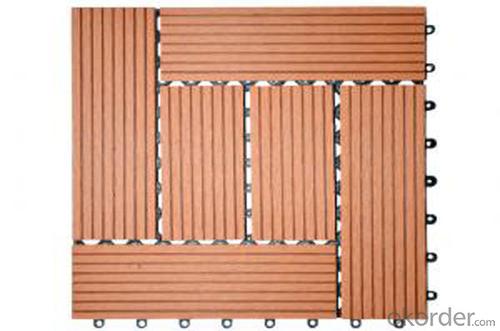

DIY WPC Decking Mosaic Floor Flooring Joint

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of DIY WPC Decking Mosaic Floor:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

Composition of DIY WPC Decking Mosaic Floor:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of DIY WPC Decking Mosaic Floor:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of DIY WPC Decking Mosaic Floor:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of DIY WPC Decking Mosaic Floor:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: What is the plastic floor and what is the compound floor?

- The floor has a new material composition, water resistance, generally suitable for public use. Composite floor, broadly speaking, refers to the structure of several layers of the composite floor, such as: laminate flooring, multi-layer solid wood flooring, bamboo flooring, etc..

- Q: How about the plastic floor?

- 1 green environmental safety, such as now almost all hospitals are using plastic floor.2 colorful, beautiful and generous.3 convenient construction, the original ground, small space.

- Q: Composite floor plastic sheeting down the impact of heat

- It's about the thickness of the 2mm, with the common "plastic cloth" is not the same thing.

- Q: You master the family, to help me, I do not care about the color of plastic bags on the floor tiles, and how to rub are not wiped out, please help me master, I will add the score

- 3, polished tiles should be regularly waxing treatment, time interval of 2-3 months is appropriate.4, such as brick surface scratches, can be applied in the scratch of toothpaste, wipe with a dry cloth can be repaired.

- Q: What is the home improvement PVC plastic floor

- Thickness. The thickness of the PVC floor is mainly determined by two aspects, that is, the thickness of the bottom layer and the thickness of the wear-resistant layer. Currently on the market more common material layer thickness: 2.0mm, 2.5mm, 3.0mm, 3.5mm, 5.0mm these five kinds, and the wear layer thickness is 0.1mm, 0.12mm, 0.2mm, 0.3mm, 0.35mm, 0.5mm, etc.. In principle, the thicker the floor, the longer the service life, of course, the higher the price. Many consumers in the purchase of plastic floor when there is a big mistake, just look at the price does not ask the thickness, so businesses tend to take the thinnest products sold to consumers. Consumers should look for a professional business PVC flooring to buy.

- Q: Plastic film on the floor for a long time with what method is easier to remove

- Can only slowly removed, with the blade can be a lot faster, I hope to help you

- Q: The advantages of plastic floor tile

- Plastic floor is another name for PVC flooring. The main component of PVC material, PVC floor can be made into two kinds, one is homogeneous, is from the bottom to the pattern material is the same. There is a composite type, is the top layer is a pure PVC transparent layer, the following with the printing layer and foam layer. "Plastic floor" refers to the use of polyvinyl chloride materials production floor. PVC floor is widely used in all aspects of home and business because of its rich color and variety of colors.

- Q: How to shop plastic floor?

- 1 ground measurement2 self leveling construction3 pre laying long Yu plastic PVC floor4 scraping glue, laying PVC plastic floor5 cleaning site

- Q: How to clean plastic floor

- 3, wash with detergent again, dry the surface of the plastic floor of the sewage, and then wash the same water again, dry the water after the completion of the. 4, clean plastic floor should pay attention to the prohibition of the use of acid cleaning agent and powdered detergent, otherwise it will damage and corrosion of the stone surface, try to avoid using rough ground to avoid the stone surface friction material, leaving a permanent scratch. 5, plastic floor cleaning standards are clean and transparent, no pollution, no trace.

- Q: Shop: composite floor below the moisture with plastic mold moisture do?

- Composite floor installation suspension installation: the first is the glue. The quality of the glue determines the quality of the floor, but also directly related to the length of service life.

Send your message to us

DIY WPC Decking Mosaic Floor Flooring Joint

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords