DIFFERENT KINDS OF CONSTRUCTION Steel-Frame Formwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

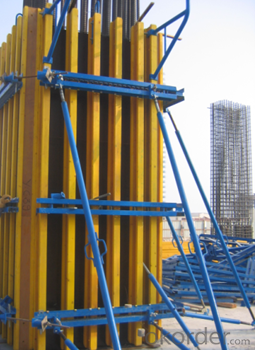

1. Structure of 140 Steel frame formwork

With adjustable flexiable sizes of frame, the 140 series steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean.

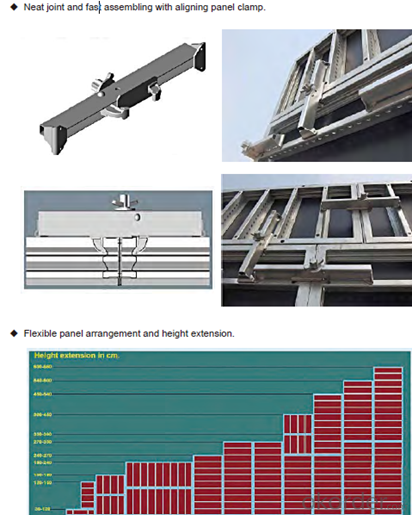

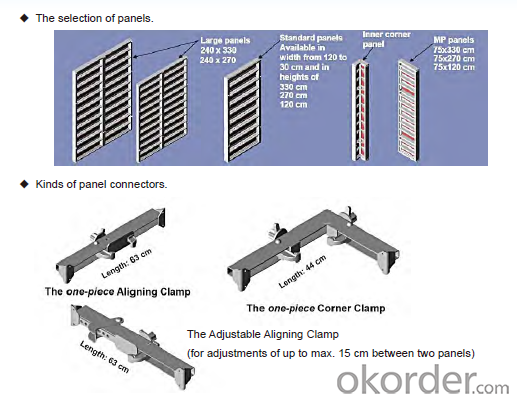

2. Main Features of 140 Steel frame formwork-Column formwork

◆ Few parts for fast forming.

◆Max. Concrete pressure: 80KN/m2.

◆Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 350px.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

3. 140 Steel frame formwork-column formwork Images

4. 140 Steel Frame Formwork Specifications

5. FAQ of 140 Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the140 Steel frame formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

- Q: Construction Engineering, moving equipment and stationary equipment, respectively

- Moving equipment refers to the rotating equipment driven by a drive (i.e., equipment with energy consumption), such as pumps, compressors, fans, etc. the energy can be electric power, pneumatic power, steam power and so on. Moving equipment refers to the main components of the movement of machinery, such as various filters, crushers, centrifuges, rotary kiln, mixer, rotary dryer and fluid conveying machinery

- Q: The building electrical iron pipe and the pipe line fixing member connected to what is called, what is called the iron pipe and the 86 fixed part of tin

- Pipe or direct protection, construction of special operation personnel of construction electrician training materials, focus on the "construction of special operations personnel management regulations", "construction of special operations personnel safety technology assessment program (Trial)", "construction of special operations personnel safety operation skills examination standard (Trial)" and other relevant provisions safety, technical knowledge and skills to master for construction electricians were explained, the book has 10 chapters, including: basic knowledge, common low-voltage electrical appliances and Motor City, power supply and grounding earthing protection system.

- Q: What are the sectors of machine building and parts processing?

- Industry to classify, it is not very strict. For example, the insurance industry, mining, energy, food, hotels, real estate services industry, garment industry, advertising industry, aerospace, aviation, chemical, chemical, construction, health care, education, training, computer, metal smelting, fire, police, soldiers, accounting, beauty, body, media, publishing, wood, paper retail, wholesale, agriculture, tourism, justice, lawyers, sports, sports, arts, entertainment, medical, art, design, banking, finance, Internet, music, dance, postal, courier, transport, consulting services.

- Q: What are the principles, performances and uses of the commonly used construction machinery equipment?

- 2.: Principle: loader loader work, powered by a flywheel of the diesel engine to the hydraulic torque converter, the torque converter will drive to the gearbox, and before and after the output flange of the gearbox, the power output of the gearbox after the transmission shaft are respectively transmitted to the front and back drive axle to drive the wheels forward. Performance: 1) Central articulated frame, turning radius is small, flexible and convenient operation in narrow space; 2) using hydraulic mechanical transmission, according to the size of the external resistance and automatic stepless speed change, which can make full use of engine power, and improve the maneuverability, simplifies the loader operation. Is to protect the transmission parts and engine; 3) adopts full hydraulic steering, power shift transmission, hydraulic or flexible manipulation, portable and flexible machine; 4) stable and reliable operation; wide use of low-pressure off-road tires, rear axle swing, with good cross-country performance and through the performance by 5); gas cap oil disc brake system and brake foot up, emergency braking system, the braking performance is safe and reliable; 6) with advanced structure and bright cab. The air conditioning system operates more comfortably. Uses: loaders are mainly used for shovel, loading, unloading, transport of soil and stone a kind of bulk materials, rock and hard soil can also be slightly shovel operations.

- Q: How are the machine parts stacked?

- Then there is a point to note, that is, from there to get used, must be put back where, so that will be organized, all things are owned by you, it will not mess.

- Q: What kind of electrical equipment do you have? What are the main components of each device?

- The utility model relates to a distribution box, belonging to a primary equipment in an electric equipment. Electrical equipment includes primary equipment and two equipment. Primary equipment is mainly power generation, power transmission, transmission, distribution, electricity and other direct generation, transmission and consumption of electrical energy equipment, such as generators, transformers, overhead lines, power distribution cabinets, switches, cabinets and so on. The two equipment is the equipment that controls, protects, measures and so on. Building or general buildings, such as cables, power distribution cabinets, motors, switches, sockets, lamps, air conditioners, electric water heaters, electricity meters, cameras, telephones, computers, etc., are electrical equipment.

- Q: Where are the mechanical pressurization air supply facilities set up?

- When the smoke proof staircase and antechamber antechamber, fire elevator or common antechamber parts can be opened outside the window, can use the natural ventilation, resulting in a stairwell with or common antechamber in the use of natural smoke exhaust with pressurized air supply arrangement of diversified combinations, and the two exhaust can not be shared.

- Q: Mechanical bearings, all types? Roughly

- The separable bearing is composed of a raceway and a needle roller and cage assembly that can be arbitrarily assembled with a punched thin raceway (W) or a machined thick raceway (WS). A non separable bearing is an integral bearing consisting of a precision machined raceway and a needle and cage assembly. This type of bearing can bear one-way axial load. With small space, it is beneficial to the compact design of machinery. Most of them only use needle roller and cage assembly, and the installation surface of shaft and shell is used as raceway surface.

- Q: Where are the hanging baskets for the building?

- It is strictly prohibited to use hanging baskets as vertical transport facilities for personnel and materials; no staff member is allowed to climb from a basket to a B basket

- Q: What functions should be achieved in mechanical structure design?

- The main features of the mechanical structure design are: (1) it is a set of thinking, drawing and calculation (sometimes necessary experiments) in one of the design process, is involved in machinery design, the most specific, the largest volume of work, in the whole process of mechanical design, an average of about 80% of the time for the structure design plays an important role in the success of mechanical design. (2) the multi solution of mechanical structure design, that is, the mechanical structure that satisfies the same design requirement, is not the only one. (3) the mechanical structure design stage is a very active design link, often needs to cross repeatedly. Therefore, in the design of mechanical structure, it is necessary to understand the basic requirements of the mechanical structure from the whole of the machine

Send your message to us

DIFFERENT KINDS OF CONSTRUCTION Steel-Frame Formwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords