CONSTRUCTION FORMWORK SYSTEMS of Steel-Frame Formwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Frame Adjustable Concrete Column Formwork :

Solid panel makes the process of the wall formwork easy and it is used in making concrete walls.To make a high concrete wall, it is necessery to use a Bracket and its attachments.

Good Features:

1.Steel Concrete formwork succeeds in minimizing imperfections in the concrete finish and creates a neat joint and tie arrangement.

2.By screw and nut connection,steel concrete formwork system does not require any spacer tubes and work takes place from only one side.

3.Concrete formwork is welded with vertical and horizontal steel ribs to reinforce the panel under heavy loads.

4.Steel concrete formwork can be used for horizontal slabs or vertical walls.

5.The flange of formwork are drilled holes every 150mm for indivisual formwork plates joint together with screws and nuts.

6.We can manufacture different sizes and plate thickness of steel formworks for the purpose of different required projects.

Product Details:

Shape | Plain,external corner,internal corner,circular |

Plate thickness | 2.5mm,3mm,4mm,5mm |

Flange height | 55mm |

Application | concrete wall,slab,beam,column,foundation,stair |

Working span | more than 10 times |

Assembly | Bolted connection |

1. Structure of Steel Frame Formwork GK120 Description

There is a prizing part designed in the corner, which can help to position and remove formwork easily.The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

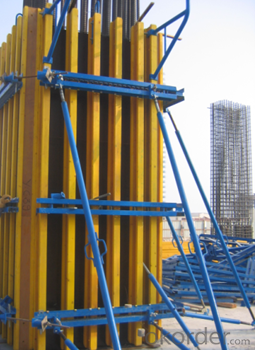

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120Specifications

Steel Frame Formwork GK120 is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

5.Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the Steel Frame Formwork GK120 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: The building electrical iron pipe and the pipe line fixing member connected to what is called, what is called the iron pipe and the 86 fixed part of tin

- The distribution of the construction site, construction machinery and electric hand-held electric tools, lighting, construction site construction site: risk factors and lightning protection, the construction site of common electrical tools and instruments, the construction site of the electricity management, common electrical fault, accidents and accident cases.

- Q: What are the sectors of machine building and parts processing?

- 3., machinery manufacturing is also a kind of industry, many industries have parts manufacturing, processing links. Therefore, the processing of parts does not belong to a particular industry.

- Q: What are the main functions of construction equipment monitoring system?

- This belongs to information management engineering. The control part is the "heart" and "brain" of the whole system. It is the command center to realize the function of the whole system. The control part is mainly composed of the main console (some systems also have a secondary console). The main function of the total console: video signal amplification and signal distribution, image correction and compensation, image signal and image signal (including switching or voice signals) record, cameras and auxiliary components (such as camera, PTZ, shield) control (remote control) and so on.

- Q: What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ limited energy or hazardous substances: conditions of actual technical and economic constraints, some risk sources can not be eradicated, then they should try to limit with energy or hazardous substances, reduce the risk of. Reduce the amount of energy or dangerous substance.

- Q: Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product quality certification, also known as product certification, internationally known as qualified certification. According to the 1991 implementation of the "people's Republic of China Quality Certification Management Regulations", the product quality certification is based on the product standard and relevant technical requirements, the certification institution confirmed by the certification and certification marks to prove that a particular product is in conformity with the relevant standards and technical requirements of the corresponding activities.

- Q: What type of industry does the machinery and building accessories processing belong to?

- Every industry has average tax rate, the contribution of each this argument does not exist, the industrial enterprise is nade VAT. The more value-added products you pay more.

- Q: What are the safety protection equipment, machinery and equipment, construction machinery and accessories for construction enterprises?

- Different types of work, security appliances are not the same. For buildings, the main safety helmets, safety nets, safety belts (San Bao), etc., for electrical operators, mainly insulated shoes, insulating gloves, insulation rod, insulation table, etc.

- Q: How are buildings, installations and materials divided?

- Provisions on the division of equipment and materials for engineering construction? [answer] the division of equipment and materials in engineering construction is directly related to the reasonable division of investment structure, budget preparation and calculation of construction output value. In order to reasonably determine the project cost, strengthen the investment in the process of construction and management, the equipment and materials in the engineering construction is unclear, especially the universal controversial common problems and put forward the principle of division of fifteen copies of "national unified installation project budget quota" of the equipment and materials are divided, the provinces, autonomous regions and municipalities directly under the central government and the relevant departments of the State Council, the Department should be combined with the local situation, formulate rules for its implementation, and report to the Ministry of construction for the record.

- Q: What is a door rack for a construction site? How high is it generally?

- This depends on the erection of the height of the general 3 steps and within 5-6 yuan a meter, assuming the erection of 4.5 meters high, 22.5-27 yuan a square. This is calculated in accordance with single-layer, the higher the more expensive, 9 meters in 65 yuan or so square. In accordance with the establishment of meters, in accordance with the erection of the volume of the calculation.

- Q: Where does Heilongjiang do the most construction machinery?

- Construction machinery is an important component of equipment industry. To sum up, all mechanical equipment necessary for comprehensive mechanical construction projects, such as earthwork construction, pavement construction and maintenance, mobile lifting, loading and unloading operation, and various construction projects, are called construction machinery

Send your message to us

CONSTRUCTION FORMWORK SYSTEMS of Steel-Frame Formwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords