DIFFERENT KINDS OF CONSTRUCTION FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

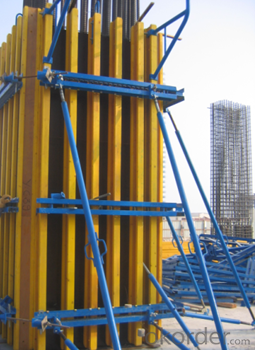

1. Structure of Timber Beam Wall Formwork Description

Timber beam wall formwork is used for the concrete pouring of wall. The application of large areas formwork has greatly increased the construction efficiency and reduced the cost. The system is convenient for construction and it is easy to control the quality. The system has two parts, formwork and pull-push props. The formwork is made of plywood, timber beam and steel waling. Pull-push props can be designed according to the project or simply select the standard props. Tie-yoke and tie-rod are used to reinforce the corner.

2. Main Features of Timber beam wall formworks

-convenient for construction

-easy to control the quality

-easy, rapid and economical.

3. Timber beam wall formwork Images

4. Timber Beam Wall Formwork Specifications

Timber beam column formwork is used for the concrete pouring of square or rectangle column. The system has the same structure and similar connection type with wall formwork.

Characteristics:

The scientifically perfect system structure design increase H beams recycling.

• Carefully dried timber, waterproof gluing, and surface coating with synthetic resin ensure dimensional stability, size retention, and a long product life.

• size retention and dimensional stability

• time and cost saving to process

• long service life through high-grade gluing

• protection against damage through specially finished support ends

• Low weight (5 kg per running meter)

5.FAQ of Timber Beam Wall Formwork

1) What can we do for you?

.We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ limited energy or hazardous substances: conditions of actual technical and economic constraints, some risk sources can not be eradicated, then they should try to limit with energy or hazardous substances, reduce the risk of. Reduce the amount of energy or dangerous substance.

- Q: What is the use of spare parts prices in Chinese market by foreign companies?

- You might be gathering information for him. You have no data for one person, if there are several people? They can analyze a lot of things through big data. You can't find out, you're OK. Once you find out, your whole life is over.

- Q: Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Three is a business license, certificate of product quality, product quality inspection certificate. Business license is the legal provisions of some industries must be licensed, and handled by the competent department of the operating permit, such as tobacco monopoly license, drug business license, business license and other dangerous chemicals.

- Q: How are the machine parts stacked?

- Then there is a point to note, that is, from there to get used, must be put back where, so that will be organized, all things are owned by you, it will not mess.

- Q: What type of industry does the machinery and building accessories processing belong to?

- Every industry has average tax rate, the contribution of each this argument does not exist, the industrial enterprise is nade VAT. The more value-added products you pay more.

- Q: Construction machinery production need to deal with what documents?

- Two, enterprise legal person business license (copy), with enterprise legal person business license duplicate copy, search three, all levels of safety production responsibility system and safety production rules and regulations directory and documents, operation procedures directory

- Q: What are the construction materials, components, fittings and equipment in construction?

- : construction engineering materials, components, fittings, equipment, each refers to: 1, engineering materials: engineering materials mainly refers to raw materials. Such as: sand, stone, steel, etc., there is no processing materials. 2, structural parts: the main structure here is the main structure of the building, the two structure and other accessories. Most of the semi-finished products and the structure of part of the installation accessories, such as: beam beam, continuous beam, beam, beam, cantilever beam, curved beam; steel, timber, concrete beam.

- Q: What are the sub projects of a construction project?

- Lime soil, sand and gravel foundation, geosynthetics foundation, fly ash foundation, dynamic compaction, foundation grouting, preloading foundation, vibroflotation foundation, jet grouting foundation, cement mixing pile foundation, soil and lime soil compaction pile foundation, cement fly ash gravel pile, cement soil pile foundation. Based on sand pile foundation

- Q: What functions should be achieved in mechanical structure design?

- The design of mechanical structure is based on the overall design, according to the principle of the program to determine and draw a specific structure, in order to reflect the required functions. Is the working principle of the abstract concrete into some parts, the specific content in determining the structure of the material, shape, size, tolerance, heat treatment and surface conditions at the same time, we must consider the process, strength, stiffness, accuracy, and other parts of the relationship between each other and other issues. So, the direct product structure design is the technical drawings, but the design work is not a simple mechanical drawing, drawing only express design language, specific integrated technology is the basic content of structural design.

Send your message to us

DIFFERENT KINDS OF CONSTRUCTION FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords