CONSTRUCTION Aluminum-Frame FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of 150 Series Aluminum Frame Formwork

150 Aluminum slab formwork system consists of two parts: steel props system with alu-frame and plywood. 150 alu-formwork, comparing with the traditional sub-girder system, can greatly improve the working efficiency and save at least 50 percent of time. The common dimension of the slab panel is 1800mm*900mm, 25.92kg weight, and the max, thickness of rein-forcement concrete slab is 400mm.

2. Main Features of 150 Series Aluminum Frame Formwork

-The complete formwork system for slab casting, easy & quick assembly.

-Light panel weight, easy to carry.

- Economical, versatile & hi-speed formwork system; comes with a permissible slab thickness of 400 mm.

- Working efficiency is greatly improved by fast erection and dismantlement.

- The panel can be supported by both props and scaffolding.

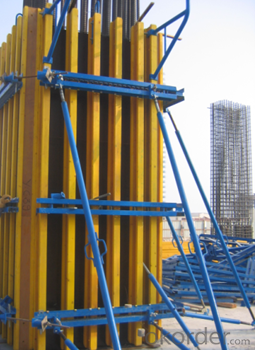

3. 150 Series Aluminum Frame Formwork images

4. 150 Series Aluminum Frame Formwork Specifications

Dimension of the standard slab panels 1800mm*900mm*150mm weight: 25.92kg

Technical data for main dimension

5. FAQ of 150 Series Aluminum Frame Formwork

1) What can we do for you?

.We can ensure the quality of the150 Series Aluminum Frame Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

- Q: The building electrical iron pipe and the pipe line fixing member connected to what is called, what is called the iron pipe and the 86 fixed part of tin

- This book is based on the characteristics of construction electrician, in accordance with the scientific, practical and applicable principles. The content is simple, the language is easy to understand, the form is illustrated, and the system, authority, operability is strong.

- Q: Changsha Sanlian Building Machinery Fittings Factory

- In addition, you can check the input path, or the name of the unit on the map. It will remind you that there is no unit in Changsha and no way. In addition, we received a fax, saying that you want to order what goods, may wish to go to the other party's local industrial and commercial Red Shield network to check whether there is this unit

- Q: Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product quality certification, also known as product certification, internationally known as qualified certification. According to the 1991 implementation of the "people's Republic of China Quality Certification Management Regulations", the product quality certification is based on the product standard and relevant technical requirements, the certification institution confirmed by the certification and certification marks to prove that a particular product is in conformity with the relevant standards and technical requirements of the corresponding activities.

- Q: Definition of large mechanical equipment?

- Usually, crane hoisting (make things up and down movement), operation mechanism (the mobile crane), luffing mechanism and slewing mechanism (the horizontal movement of goods), plus metal mechanism, driving device, control device and the necessary auxiliary assembly.

- Q: How do the welding parts in the welding drawings of the machine parts indicate the technical requirements of the drawings?

- Therefore, the medium carbon steel has the most extensive application in the medium strength level. Besides being used as building material, it is widely used in the manufacture of various mechanical parts. Welding: 1 the preheating is conducive to reducing carbon steel heat affected zone is the most

- Q: What are the mechanical drawing software?

- The plane is mainly CAD and CAXA, there are some non mainstream mechanical engineer what, mainly engaged in your spare parts of machinery industry, roughness, form and position tolerance requirements, recommendations for CAXA, which symbols are readily available, there are standard parts library, mechanical symbols library etc..

- Q: What are the world famous mechanical equipment exhibition?

- 1, the German BMW Exhibition (BAUMA) sponsored by: Messe M nchen GmbH, held every three years, has held 30 sessions, the thirty-first will be in April 2016 11-17 in the German city of Munich exhibition centre. The German international engineering machinery, building materials machinery, mining machinery, construction vehicles and Equipment Expo is the world's largest and most influential international engineering machinery, building materials machinery, mining machinery industry exhibition, every three years regularly held in Munich in germany. The fair combines science and technology, trade, information and technical cooperation

- Q: What is a door rack for a construction site? How high is it generally?

- This depends on the erection of the height of the general 3 steps and within 5-6 yuan a meter, assuming the erection of 4.5 meters high, 22.5-27 yuan a square. This is calculated in accordance with single-layer, the higher the more expensive, 9 meters in 65 yuan or so square. In accordance with the establishment of meters, in accordance with the erection of the volume of the calculation.

- Q: Where does Heilongjiang do the most construction machinery?

- In the world, the industry address basic similar, of which the United States and Britain called the construction machinery and equipment, construction machinery and equipment for Germany, Russia called for the construction and road construction machinery, construction machinery called japan. In China, some products are also known as construction machinery, and in the mechanical system, according to the State Council to set up the industry approval, collectively referred to as construction machinery, has continued to the present

- Q: What are the sub projects of a construction project?

- Appendix B Construction Engineering Division (sub branch) engineering, sub project division, B.0.1 Construction Engineering Division (sub branch), engineering, sub projects can be divided into table B.0.1. Table B.0.1 division number of construction works, sub works and sub projects

Send your message to us

CONSTRUCTION Aluminum-Frame FORMWORK SYSTEMS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords