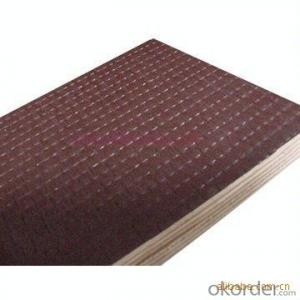

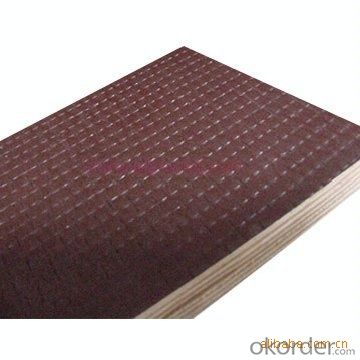

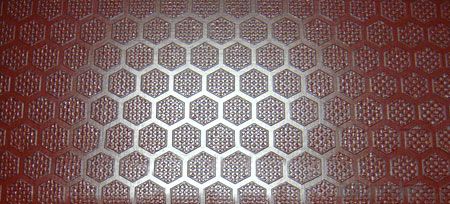

4x8 Diamond Design Anti-Slip Poplar Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification

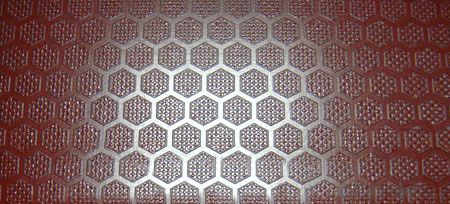

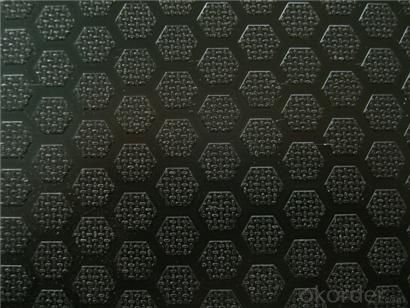

Anti-slippery film faced plywood

Size:1220X2440mm ,1250X2500mm

Glue:MR,WBP

Core:poplar,hardwood,combi

F/B:balck,brown,red

Description

Size: | 1220*2440cm or as request |

core | poplar,pine,birch,hardwood,etc |

Film | black film |

Face | film faces one sides or two |

Feature | strong nailing strength and easy to be coated |

Processing of pressing | Third or second |

Determination of gule strength | 2.96Mpa |

Moisture content | 7-15% |

Elastic modulus | 5000-6000mPA |

Features:

1. No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2. Good performance and more turnover use time.

3. It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4. Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5. This can moderate and contact 30% time for a project.

6. Corrosion resistant and ir will nor pollute the surface of concrete.

7. It is good to keep performance warm,ia favorable to make constrution in winter.8. Products can be made into warping plywood

9. It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different types.

FAQ:

Q1.What are the advantages of Anti-Slippery Film Faced Plywood?

A1:

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: Plywood in the material defects?

- discoloration discoloration Where the normal color of wood changes called color, can be divided into two kinds of chemical discoloration and fungal discoloration.

- Q: The difference between the multilayer board and the plywood is as follows

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: How do I determine if plywood contains formaldehyde?

- because it is often hidden behind the wood epidermis and must be carefully viewed, usually in seams and drills Of the place can be seen clues

- Q: Plywood is a common material for furniture?

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood

- Q: The Preparation of plywood ingredients

- central layer central ply plywood center layer, the other layers are symmetrically arranged on both sides of it.

- Q: What are the defects in plywood material?

- Fracture split, end split The fiber is separated in the direction of the grain, usually starting from one end and extending through the thickness of the morning plate

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: Multilayer board, also known as three plywood and plywood

- . Its main advantages and disadvantages of raw materials, Liu An core 1.2m.4m each board price of 10-20 yuan. And the peach core and poplar will be cheaper.

- Q: Distinguish between multilayer boards and plywood

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials.

- Q: For the plywood environmental advice?

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

Send your message to us

4x8 Diamond Design Anti-Slip Poplar Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords