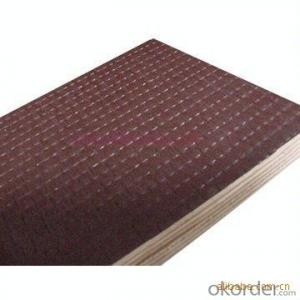

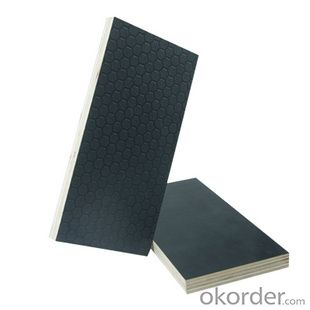

Diamond Design Anti-slip Black or Brown Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

Diamond Design Antil-Slippery Film Faced Plywood are widely used in construction repeatly.

Characters:

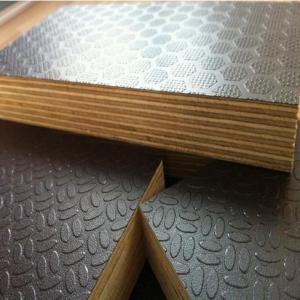

Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

1. Film: dynea brown film,brown chinese film,black chinese film,red film etc.

2. Core:poplar,birch,hardwood,combined.

3. Glue:WBP ,Melamine,MR,E0,E1,E2

4. Size:1200*2400,1220*2440,1250*2500,the thickness is 3.0-30MM.

5. Mositure:8%-14%

6. Price term:FOB,CIF

7. Payment: 30%T/T for deposit and the balance against the copy of B/L. And the L/C at sight is also available for the first order.

8. Package: Standard export package:Inner with waterproof plastic bag, outside with 3mm plywood and carton,then fastened with 3'x6' sheet iron and packed with pallet.

Detailed Specification:

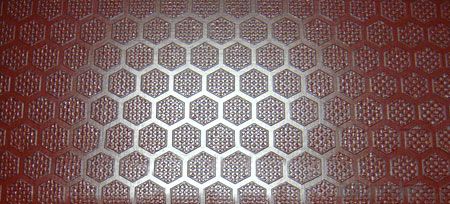

Product name: Anti-Slippery Film Faced Plywood

1) Size: 1220×2440mm, 1250×2500mm,1500×3000mm,1525×3500mm, or as request

2) Thickness: 4-100mm

3) Glue: MR, Melamine,WBP Core: Poplar, Birch, Pine, Hardwood,etc

4) Surface: Imported Brown/Black Film; Chinese Brwon/Black Film

5) Anti-slip Pattern: Diamond

6) Special Treatment: Bevel, Tongue & Groove,Punch, etc

7) Moisture Content: 8-14%

8) Application: Concrete forming, Platform, Cassette Systems and Trailer Flooring, etc.

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.What are the advantages of Anti-Slippery Film Faced Plywood?

A1:

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Quality grade for the premium, one, two, three a total of four, the indicator is similar to the MDF, but the intensity is much higher than the MDF

- Q: Judging wood is the standard for plywood

- Rare wood is only used to make very upscale furniture, and is often used in combination with lower-priced wood

- Q: Commonly used plywood, pallets and so on

- Is the destruction of the physical properties of the wood itself, which played a leading role in the composition of the plastic

- Q: Multilayer board and plywood difference

- multi-layer board is one of the commonly used materials processing enterprises, is a wood-based panel

- Q: A brief introduction to plywood

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood.

- Q: The density of the plywood is greater than that of the same kind of wood

- The greater the unit pressure when gluing, the greater the density of the plywood. As the wood at high temperature easy to produce plastic deformation, hot glue gluing than the compression of the compression rate is greater.

- Q: Material for the plywood defects which

- Decay rot due to the invasion of wood rot fungi, the cell wall material decomposition, resulting in loose wood, strength and density decreased, wood tissue and color are often changing.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- and the dashboard and the inner panel are arranged symmetrically on both sides of the center layer or the core.

- Q: What is medium density fiberboard

- Its thickness specifications are 2.7,3,3.5,4,5,5.5,6,7,8 mm, commonly used specifications are 3,3.5,4 mm.

Send your message to us

Diamond Design Anti-slip Black or Brown Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords