3/4 in Combi Core Poplar Core and Hardwood Core Black Film Faced Plywood 4x8

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

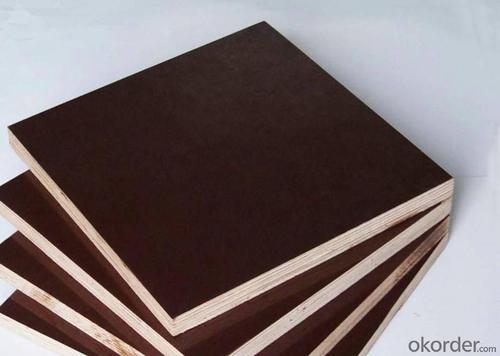

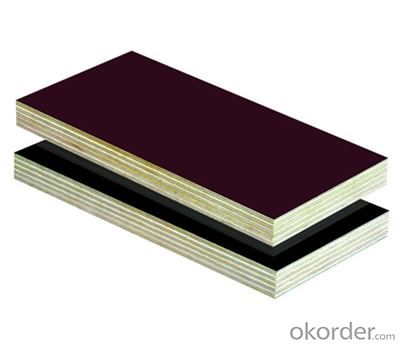

Specifications of Combi Core Black Film Faced Plywood

1.Usage:Decoration,Furniture,Construction.

2.Package:Inter packing:0.2mm plastic bag. Outer packing:Pallets are coverd with plywood or carton

3.Min order 1*20FCL or 23 cubic meter

4.Payment terms:L/C at sight,T/T 30% as deposit ,D/P.

5.Supply ability:6000 Cubic meter/month or 8000 pcs/day.

6.Main marke:Indonesia Malaysia India,Thariland,Middle East,Europe,Africa.

Description

| Marine plywood/Film Faced Plywood | ||

| Film | Brown film, Black film | |

| Core | Poplar, hardwood, pine and others | |

| Glue | WBP,Melamine,MR | |

| Size(mm) | 1220*2440, 1250*2500, or requested by customers | |

| Thickness(mm) | 6-27mm | |

| Density | >550-650g/CBM | |

| Moisture | 8-12% | |

| Modulus of Elasticity | >6000Mpa | |

| Modulus of rupture | >30Mpa | |

| Quantity | 20GP | 8 pallets/21M3 |

| 40GP | 16 pallets/42M3 | |

| 40HC | 18 Pallets/53M3 | |

| Min Order | 1*20 ft container | |

| Payment | T/T or L/C at sight | |

| Delivery time | Within 2 weeks after receiving deposit or Original L/C at sight | |

| Addition | Sample available | |

| film faced plywood pictures | ||

Features:

1. No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2. Good performance and more turnover use time.

3. It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4. Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5. This can moderate and contact 30% time for a project.

6. Corrosion resistant and ir will nor pollute the surface of concrete.

7. It is good to keep performance warm,ia favorable to make constrution in winter.8. Products can be made into warping plywood

9. It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different types.

FAQ:

Q:What are Advantage of Combi Core Black Film Faced Plywood?

A:As below:

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- the minimum number of layers of each nominal thickness to comply with the relevant provisions.

- Q: What is the composition of the plywood?

- Glue plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression.

- Q: How to use building plywood?

- Building plywood is mainly used in outdoor conditions, such as building decoration and concrete template

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- For example: Yunshan plywood is a soft Murray plywood, it can be used for housing flooring, walls and ceiling, coated surface can also be sprayed after the coating.

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- Plywood also has solid wood plywood, in general, solid wood panels will be more expensive than plywood

- Q: Contemporary plywood market development

- but also China's development of plywood industry cost accounting and other plywood production countries compared to the advantages of an important factor. China plywood product quality itself

- Q: What types of plywood can be divided into?

- and soft wood decoration Plywood (used for construction, furniture, vehicles, ships and other high-level decorative materials), plywood type according to the bonding strength is divided into

- Q: What is the type of plywood editing?

- decorative plywood (for construction, furniture, vehicles and ship decoration materials), the general use of plywood (for packaging, bedding and other uses)

- Q: The Decorative veneer veneer plywood grade classification

- for example,such as some manufacturers logo level "AAA", which is corporate behavior.

- Q: Hard fiber board is also a density board

- , the same tree species or similar tree species, the same processing method (peeling or slicing)

Send your message to us

3/4 in Combi Core Poplar Core and Hardwood Core Black Film Faced Plywood 4x8

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords