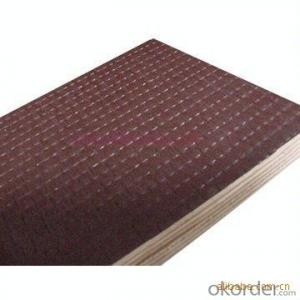

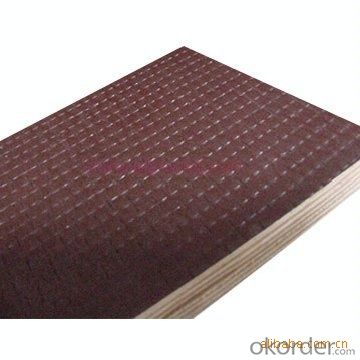

Square Design Anti-Slippery Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

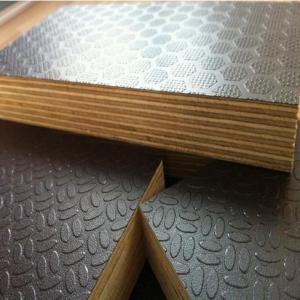

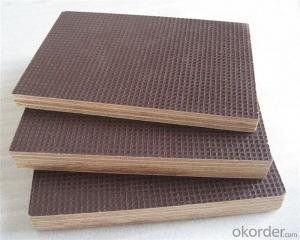

Square Design Antil-Slippery Film Faced Plywood are widely used in construction repeatly.

Characters:

Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

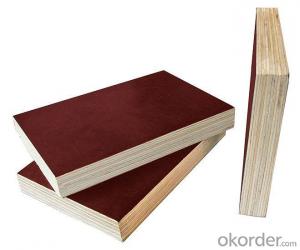

Name | Film faced plywood |

Material | Poplar, combi core, hardwood,brich |

Size | 1220*2440/ 1250*2500 mm,or as per your request |

Thickness | 9-25mm |

Glue | E2, E1, E0,Melamine,WBP, MR |

Density | 500-600 kgs/m3 |

Face/back | Brown, black |

MC | Below 14% |

Certificate | CARB, CE, ISO9001,ISO14001, |

Used time | More than 10 times |

Usage | Construction etc |

Detailed Specification:

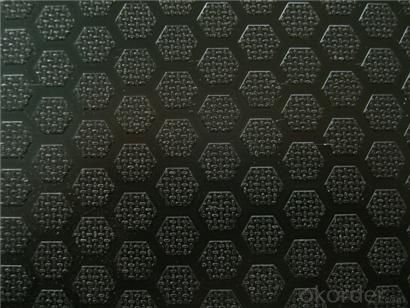

Product name: Anti-Slippery Film Faced Plywood

1) Size: 1220×2440mm, 1250×2500mm,1500×3000mm,1525×3500mm, or as request

2) Thickness: 4-100mm

3) Glue: MR, Melamine,WBP Core: Poplar, Birch, Pine, Hardwood,etc

4) Surface: Imported Brown/Black Film; Chinese Brwon/Black Film

5) Anti-slip Pattern: Square

6) Special Treatment: Bevel, Tongue & Groove,Punch, etc

7) Moisture Content: 8-14%

8) Application: Concrete forming, Platform, Cassette Systems and Trailer Flooring, etc.

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.What are the advantages of Anti-Slippery Film Faced Plywood?

A1:

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: What does plywood mean and its synthesis?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: How do you choose plywood in plywood production?

- But should be described in the name of the product, such as "cedar veneer plywood", or "fir slices plywood", or "cherry wood trim".

- Q: What is the use of plywood for construction?

- Plywood is the direction of the logs along the ring to cut into large sheets of single board, after drying, after coating by the adjacent veneer layer grain direction perpendicular to the principle of the billet, glued from the plate.

- Q: Multilayer board, also known as three plywood and plywood

- the plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: Now the market prospects for plywood

- total accumulated profit 3,198,494,000 Yuan, compared with the same period in 2005 increased by 60.41%.

- Q: What is the density of plywood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material,

- Q: Distinguish between multilayer boards and plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- Mild wood veneer: with Ash, willow wood, color wood, birch and other peeling into 0.1-0.5mm thick sheet, plywood as a substrate made of glued, its beautiful pattern, good decorative

- Q: What kind of glue is today's plywood?

- if you want to make outdoor use of wood products, you can use E1 grade (or even E0 level) phenolic glue.

- Q: What is the plywood made of wood?

- Production of plywood main tree species are: camphor, willow, poplar, eucalyptus, fir and so on

Send your message to us

Square Design Anti-Slippery Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords