Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

1.Weight and Hardness of Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

Nominal diameter | Diameteical Tolerance | Weight of single ball in average | Surface hardness | Impact toughness |

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) |

Φ20 | +2 -1 | 32 | 55-65 | ≥12 |

Φ25 | 64 | |||

Φ30 | 110 | |||

Φ40 | 263 | |||

Φ50 | 513 | |||

Φ60 | +3 -2 | 888 | ||

Φ70 | 1410 | |||

Φ80 | 2104 | |||

Φ90 | 2996 | |||

Φ100 | 4110 | |||

Φ110 | +4 -2 | 5457 | 50-60 | |

Φ120 | 7102 | |||

Φ130 | 9030 | |||

Φ140 | +4 -3 | 11278 | ||

Φ150 | 13871 |

2.Physical Property of Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

Material | Impact Test(Ak.J/cm²) | Endurance Test Times(5m/T) | Surface Hardness (Φ25mm- Φ60mm) | Core Hardness (Φ25mm- Φ60mm) | Surface Hardness (Φ70mm- Φ100mm) | Core Hardness (Φ70mm- Φ100mm) | Breakage |

50Mn | ≥12 | ≥10000 | ≥56 | ≥35 | ≥56 | ≥28 | <0.5% |

60Mn | ≥13 | ≥10000 | ≥58 | ≥38 | ≥58 | ≥29 | <0.5% |

65Mn | ≥15 | ≥12000 | ≥60 | ≥42 | ≥60 | ≥30 | <0.5% |

B2 | ≥17 | ≥12000 | ≥60 | ≥52 | ≥60 | ≥50 | <0.5% |

75SiMn | ≥16 | ≥12000 | ≥60 | ≥50 | ≥60 | ≥48 | <0.5% |

Wear-resistant Alloy | ≥17 | ≥12000 | ≥60 | ≥54 | ≥60 | ≥48 | <0.5% |

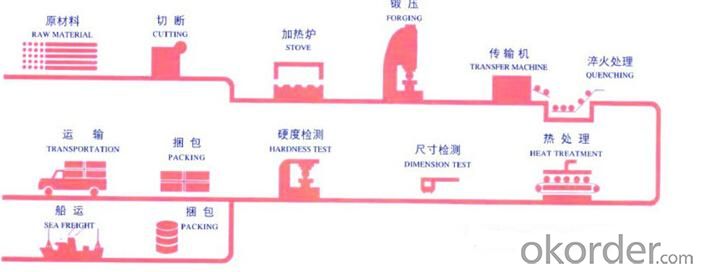

3.Production Process of Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

3.Packing Ways of Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Buffing should be better, to see how your embryo, but a bit difficult

- Q: Is the cast steel a casting part?

- Cast steel is one of the casting parts that you call. The material is made of carbon steel or alloy steel, stainless steel, etc. the method is cast

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Steel deformation control is one of the most common problems in the metal processing industry. Any process will occur. The casting is the largest deformation and the least fine. It is generally used to produce blank blanks

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to the grade of the parts, according to the relevant standards, the regular drawings will be noted in the technical requirements of the parts.

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- Yes, the cast aluminium is polarized and gray, but the key problem is to guarantee the quality of the aluminium casting, and the quality of the other aluminium casting is not good.

- Q: Heat treatment process and purpose of casting parts

- Methods: artificial aging or natural aging (also called normalization) treatment.Artificial aging: heating to 2-3 Baidu, it is best to apply mechanical vibration, and maintain a period of time.

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger,

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Dia20mm-Dia150mm Forged Steel Grinding Ball for Ball Mill Use with High Hardness and Good Wear Resistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords