DI Pipes in Water Infrastructure,Ductile Iron Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

DI Pipes in Water Infrastructure

Ductile iron pipe is a pipe made of ductile iron commonly used for potable water transmission and distribution.

Specifications:

1. ISO 2531 & EN 545 Standard

2. K8, K9, K10 C Class

3. Internal Linings: Portland Cement

4. External Coating: Bitumen/ Epoxy

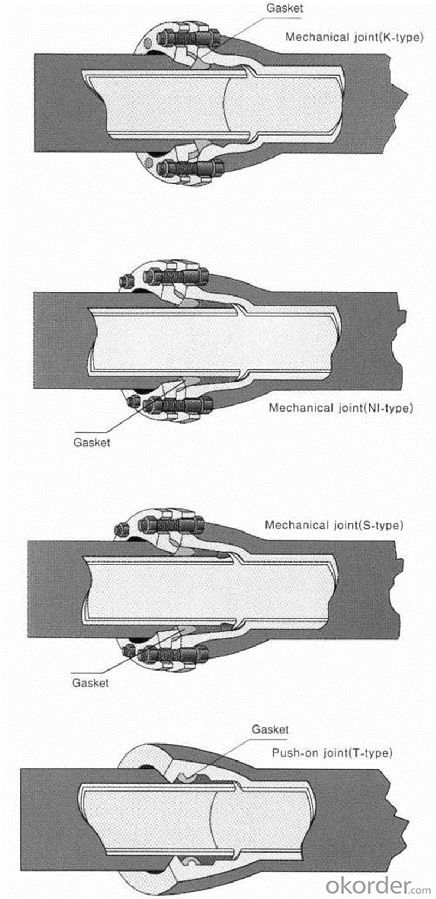

5. Joint Type: T Joint, K Joint, N1 Joint, MJ Joint and Flange Joint.

| DN(mm) | OD(mm) | Wall Thickness(mm) | Weight of Socket (kg) | Unit Weight for Barrel (kg/m) | Total Weight(kg) (Standard Length=6000mm) | ||||||

| K8 | K9 | K10 | K8 | K9 | K10 | K8 | K9 | K10 | |||

| 80 | 98 | 6 | 6 | 6 | 3.7 | 12.2 | 12.2 | 12.2 | 76.8 | 76.8 | 76.8 |

| 100 | 118 | 6 | 6.1 | 6.1 | 4.7 | 14.9 | 15.1 | 15.1 | 94.1 | 95.4 | 95.4 |

| 150 | 170 | 6 | 6.3 | 6.3 | 8.5 | 21.8 | 22.8 | 22.8 | 139.4 | 145.4 | 145.4 |

| 200 | 222 | 6 | 6.4 | 6.4 | 10.9 | 28.7 | 30.6 | 30.6 | 183.6 | 194.6 | 194.6 |

| 250 | 274 | 6 | 6.8 | 7.5 | 15 | 35.6 | 40.2 | 44.3 | 228.8 | 255.8 | 280.8 |

| 300 | 326 | 6.4 | 7.2 | 8 | 22.2 | 45.3 | 50.8 | 56.3 | 293.3 | 326.3 | 360.3 |

| 350 | 378 | 6.8 | 7.7 | 8.5 | 26.5 | 55.9 | 63.2 | 69.6 | 361.8 | 405.8 | 443.8 |

| 400 | 429 | 7.2 | 8.1 | 9 | 32.5 | 80 | 75.5 | 83.7 | 433 | 482 | 532 |

| 500 | 532 | 8 | 9 | 10 | 50.6 | 92.8 | 104.3 | 116 | 607.8 | 676.8 | 743.8 |

| 600 | 635 | 8.8 | 9.9 | 11 | 71.9 | 122 | 137.3 | 152 | 803.6 | 894.6 | 983.6 |

| 700 | 738 | 9.6 | 10.8 | 12 | 85.3 | 155 | 173.9 | 193 | 1015 | 1129.2 | 1243.2 |

| 800 | 842 | 10.4 | 11.7 | 13 | 108.7 | 192 | 215.2 | 239 | 1261 | 1400.1 | 1543.1 |

| 900 | 945 | 11.2 | 12.6 | 14 | 140.1 | 232 | 260.2 | 289 | 1532 | 1701.1 | 1874.1 |

| 1000 | 1048 | 12 | 13.5 | 15 | 174.3 | 275 | 309.3 | 343 | 1824 | 2030 | 2234 |

| 1200 | 1265 | 13.6 | 15.3 | 17 | 267.5 | 374 | 420.1 | 466 | 2512 | 2787.8 | 3063.8 |

- Q: What are the different methods for joining ductile iron pipe?

- There are several methods for joining ductile iron pipe, including mechanical joints, flanged joints, push-on joints, and restrained joints. Mechanical joints use a rubber gasket and a series of bolts and glands to create a secure connection. Flanged joints involve bolting two flanges together with a gasket in between. Push-on joints utilize a rubber gasket and require the pipe to be pushed into the joint. Restrained joints use a combination of mechanical joints and a restraining gland to prevent movement and provide a secure connection.

- Q: Can ductile iron pipes be used for bridge piers?

- Yes, ductile iron pipes can be used for bridge piers. Ductile iron pipes are known for their high strength and durability, making them suitable for various applications, including bridge construction. They have excellent resistance to corrosion and can withstand heavy loads, making them a reliable choice for supporting bridge piers. Additionally, ductile iron pipes offer ease of installation and maintenance, which can be advantageous in bridge construction projects. However, it is important to consider the specific requirements and design specifications of the bridge before selecting ductile iron pipes as the material for bridge piers. Proper engineering evaluation and consideration of factors such as load capacity, soil conditions, and environmental factors are essential to ensure the suitability and safety of using ductile iron pipes for bridge piers.

- Q: Does centrifugal cast iron pipe work well with lining cement? Will it scale and breed bacteria?

- From the centrifugal ductile cast iron pipe with cement production process to analysis, the most core pipe by centrifugal molding, concrete water cement ratio, the centrifugal force, the coarse aggregate to the outer wall of the pipe and the pipe inside; because of fine aggregate and water removal, strength and wear resistance variation. When the inner wall of the pipe by long-term washing and soaking water, and inner wall wear and erosion, as the roughness increases, head loss increases, you will need to increase the pump lift, and operation cost for power consumption increases, also greatly increased.

- Q: Can ductile iron pipes be used in culvert or storm sewer applications?

- Certainly, culvert or storm sewer applications can make effective use of ductile iron pipes. Renowned for their strength, durability, and flexibility, ductile iron pipes are an excellent choice for such purposes. They possess the capability to endure heavy loads, resist corrosion, and handle high flow rates, thus establishing them as a dependable option for culverts and storm sewers. Moreover, their extended lifespan and low maintenance needs further contribute to their appropriateness in these applications. Furthermore, ductile iron pipes can be easily installed and are available in various sizes and configurations to suit the specific requirements of culvert or storm sewer projects. In summary, ductile iron pipes have been extensively employed and proven to be an efficient and long-lasting solution for culvert or storm sewer applications.

- Q: The benefits of ductile iron castings

- Nodular cast iron has developed rapidly to be second only to grey cast iron and widely used as cast iron material. The so-called "iron instead of steel", mainly refers to ductile iron

- Q: What are the disadvantages of using ductile iron pipes?

- There are several disadvantages associated with using ductile iron pipes in various applications. Firstly, ductile iron pipes tend to be more expensive compared to other types of pipes, such as PVC or HDPE. This can be a significant drawback for projects with budget constraints. Secondly, ductile iron pipes are relatively heavy, which makes transportation and installation more labor-intensive and time-consuming. This can increase the overall cost of the project, especially when considering the need for specialized equipment and a skilled workforce. Another disadvantage is that ductile iron pipes are susceptible to corrosion. Over time, exposure to various environmental factors, such as soil conditions and water chemistry, can lead to the formation of rust and scale on the inner and outer surfaces of the pipe. This can reduce the pipe's lifespan and potentially affect water quality. Furthermore, ductile iron pipes can be prone to cracking or breaking under certain conditions, especially if exposed to heavy loads or significant ground movement. This can result in costly repairs or replacements, leading to additional expenses and disruptions to the water supply. Lastly, ductile iron pipes have a relatively low resistance to impact and abrasion compared to some other materials. This means they may be more prone to damage from external forces, such as construction activities or accidental impacts, which can further increase maintenance and repair costs. Overall, while ductile iron pipes have their advantages, such as high tensile strength and durability, it is important to consider these disadvantages before deciding on their use in a particular project.

- Q: What are the common causes of failure in ductile iron pipes?

- There are several common causes of failure in ductile iron pipes. One major cause is corrosion. Over time, the exposure to water, soil, and other environmental factors can lead to the formation of rust and corrosion on the pipe's surface. This can weaken the structural integrity of the pipe and eventually lead to failure. Another common cause is improper installation or handling. If the pipes are not installed correctly or if they are mishandled during transportation or installation, it can result in cracks, fractures, or other physical damage. These defects can compromise the functionality of the pipe and contribute to its failure. Inadequate design is another factor that can lead to failure. If the pipe is not designed to withstand the anticipated loads, pressures, or environmental conditions, it can become susceptible to premature failure. The pipe's material properties, wall thickness, and diameter must be carefully considered during the design process to ensure it can handle the expected demands. Poor maintenance and lack of timely repairs can also contribute to failure. Regular inspections, maintenance, and prompt repairs are necessary to identify and address any issues before they escalate. Failure to do so can result in the gradual deterioration of the pipe, making it more prone to failure. Lastly, external factors such as soil movement, seismic activity, or excessive traffic loads can also cause failure in ductile iron pipes. These external forces can exert stress on the pipe, leading to cracks, fractures, or even complete failure. To prevent failure in ductile iron pipes, it is essential to employ proper corrosion protection techniques, follow correct installation procedures, ensure adequate design considerations, implement regular maintenance and repair programs, and account for external factors during the planning and installation process.

- Q: Do rigid cement cast iron pipes need cement piers?

- Ductile iron pipes mainly called centrifugal ductile iron pipe, it has the properties of nature, iron and steel, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc.. Water supply pipe is the first choice, with high cost performance. Compared with the PE pipe, from the installation time, ductile pipe PE pipe installation is simple and rapid, and after the installation of internal and external pressure bearing better tightness and corrosion resistance; from the point of view, ductile pipe sealing better after installation, but also can improve the corrosion resistance of corrosion protection through a variety of means; from the hydraulic performance, because ductile pipe specifications generally refers to the inner diameter of PE pipe diameter specifications generally refers to the same specifications, because under the condition of ductile pipe can achieve greater runoff; from the installation and maintenance cost, ductile pipe have more favorable price. The main components of ductile iron pipes are carbon, silicon, manganese, sulfur, phosphorus and magnesium. The inner wall of zinc spray, anti-corrosion materials such as cement mortar.

- Q: How can stainless steel pipes and ductile iron pipes be joined?

- Or with a gland type expansion joint, by tightening the pressure plate bolts, sealing pipe fittings and pipe wall, so as to achieve sealing, while retractable function

- Q: How are ductile iron pipes protected against stray electrical currents?

- To safeguard water and sewer systems, ductile iron pipes are shielded from stray electrical currents through a technique called cathodic protection. This process entails the application of a low-voltage direct current (DC) to the pipes, generating a defensive electrical field around them. To achieve cathodic protection, sacrificial anodes or impressed current systems are installed near the ductile iron pipes. Sacrificial anodes, composed of a more electrically active metal like zinc or magnesium, are connected to the pipes and act as the electrical current source. Over time, these anodes corrode, sacrificing themselves to shield the pipes from corrosion caused by stray electrical currents. However, impressed current systems utilize an external power source to supply the protective electrical current. Rectifiers are employed to convert alternating current (AC) to direct current (DC), which is then administered to the pipes through anodes. This approach provides greater control over the amount of current applied, ensuring optimal protection. In both scenarios, the electrical current flowing through the sacrificial anodes or impressed current systems establishes a protective barrier around the ductile iron pipes. This barrier impedes the flow of stray electrical currents through the pipes, thus diminishing the risk of corrosion and prolonging the infrastructure's lifespan. Regular monitoring and maintenance of the cathodic protection system are crucial to uphold its efficacy. This involves inspecting the anodes, assessing the levels of electrical current, and making any necessary adjustments or replacements to maintain the desired level of protection. To summarize, cathodic protection is a dependable and widely utilized method for safeguarding ductile iron pipes against stray electrical currents. By preserving the integrity and longevity of water and sewer systems, it plays a vital role in ensuring their functionality.

Send your message to us

DI Pipes in Water Infrastructure,Ductile Iron Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords