DI Pipe Fitting ISO2531/EN545/EN598,for water project

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

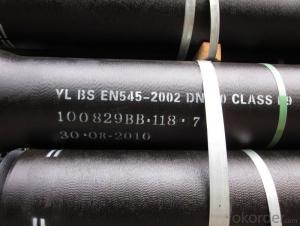

DI Pipe Fitting,Class K12,K14

Suppply Potable/Sewage Water

Standard:ISO2531/EN545/EN598

Competitive Price & Good Service

DI pipe fitting

Key Specifications:

Material : Ductile Cast Iron

Tee/Cross/Bends/Taper/Collar/Cap/Flange Socket/Flange Pipes with Puddle/Duck foot Bend/Flange Bell Mouth/

Size Range : DN 50mm to DN 2600mm

Joint Type : Flange PN10,16,25Bar/ Socket/K Type with Mechanical Gland

Manufacture Standard: ISO 2531/ EN545/EN598/AWWA C110 and C153

Casting Method: Lost foam technique

Annual capacity : 10,000 tons

Coating Exterior: zinc 130g/m2 and bitumen coating 70 microns.

Cement Lining Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement.

Special requirements on external coating and internal lining can be applied

We also provide accessories such as SBR/EPDM rubber gaskets, bolts&nuts.

Additional Parts:

Each fitting is strictly inspected according to ISO standard to ensure permanently high performance.

Easy Installation at site and service free for life

Long Service Lifespan

Quotation will arrive you within 24hours once we get your inquiry.

We guarantee offering a competitive price to you.

A copy of original inspection reports of pipes will be offered after shipment.

Photos of loading process will be sent to the customer after shipment effect.

We will follow-up the delivery progress after shipment effect and update to the customer on weekly basis

- Q: Does the cast iron pipe for spheroidal graphite need corrosion protection when laying underground?

- Ductile cast iron pipe after annealing, the microstructure is ferrite and pearlite, good mechanical properties, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc..

- Q: Principles for the antiseptic treatment of ductile iron pipes

- 4. epoxy ceramic liningEpoxy ceramic lining is suitable for sewage pipes and gas pipelines, but because of its difficult manufacturing process and high cost, it has some limitations in its use. Epoxy ceramic lining has a high adhesion and finish. It is an excellent anti-corrosion coating.5. aluminate cement coating or sulphate cement coatingThese two special cement coatings are suitable for internal corrosion protection of nodular iron pipes used in sewage pipes to improve the corrosion resistance of acid and alkali components in sewage.

- Q: Can ductile iron pipe be used for both water and wastewater applications?

- Yes, ductile iron pipe can be used for both water and wastewater applications. Ductile iron is a type of iron that has been treated with small amounts of magnesium to create a more flexible and durable material. This makes it suitable for transporting both water and wastewater. Ductile iron pipes are known for their high strength and resistance to corrosion, making them ideal for underground applications. They can handle the high pressures and varying flow rates associated with water distribution systems, as well as the corrosive nature of wastewater. Additionally, ductile iron pipes have a longer lifespan compared to other materials commonly used in water and wastewater applications, such as PVC or concrete. Therefore, they are often chosen for projects that require a reliable and long-lasting pipe material for both water and wastewater transport.

- Q: What are the environmental benefits of using ductile iron pipe?

- Using ductile iron pipe in various applications brings numerous environmental benefits. Firstly, ductile iron is an incredibly durable material that can endure harsh environmental conditions and has a long lifespan. As a result, the need for frequent pipe replacements is significantly reduced compared to other materials, leading to a decrease in resource-intensive manufacturing processes and the disposal of old pipes. Secondly, ductile iron pipes possess exceptional corrosion resistance properties, which lowers the risk of leaks and pipe failures. This not only prevents potential water contamination but also minimizes water wastage. Furthermore, ductile iron is a recyclable material. When the pipes reach the end of their useful life, they can be melted down and used to create new products. This reduces the demand for virgin materials and conserves natural resources. Moreover, the manufacturing process of ductile iron pipes has greatly improved over time, resulting in reduced energy consumption and emissions. Many manufacturers now utilize energy-efficient technologies and practices, contributing to a lower carbon footprint and decreased air pollution. Lastly, ductile iron pipes have a smooth internal surface that minimizes friction and allows for efficient water flow. This leads to energy savings in pumping and distribution systems, as less energy is required to transport water through the pipeline network. Overall, the utilization of ductile iron pipe positively impacts the environment by reducing waste, conserving resources, minimizing pollution, and enhancing energy efficiency in water distribution systems.

- Q: Are ductile iron pipes recyclable?

- Indeed, it is true that ductile iron pipes possess recyclability. Ductile iron, which belongs to the cast iron family, showcases exceptional sturdiness and endurance, rendering it an ideal selection for a wide array of applications, encompassing water and sewage systems. Once these pipes surpass their lifespan, they can undergo recycling and repurposing. The recycling procedure involves the fusion of the ductile iron pipes, employing the molten metal to generate fresh pipes or alternative iron-based commodities. By recycling ductile iron pipes, not only do we contribute to the conservation of natural resources, but we also curtail the volume of waste that inundates landfills. Hence, ductile iron pipes are perceived as a sustainable and eco-friendly alternative for piping systems.

- Q: General cast iron prices now

- Hubei, Suizhou, in 2010, normally 5000-7000 tons of iron, if required to join copper and other metals, the price is calculated. The price is very low, because the market price in Suizhou is the lowest in the whole country. Under normal circumstances, it should be 8000 tons a ton

- Q: Does the cast iron have size 250? What's the performance?

- You should be the casting grade or material, if it is ductile iron, said generally between QT400-15 or QT700-2 different indicators, said in front of the tensile strength, the elongation rate refers to the back, China is now the lowest grade of nodular cast iron material is QT400-15, such as QT250.In addition, the number 250 you refer to may also be a code name for ductile iron parts, such as 200, 300, etc., which are manufactured by the factory as required by the project.Gray iron, which has a 250 brand, is generally referred to as HT250, but it is not ductile iron.The machine on the ductile iron and gray iron are used, but generally not made of grey cast iron gear

- Q: Are ductile iron pipes suitable for use in cooling water systems?

- Yes, ductile iron pipes are suitable for use in cooling water systems. They offer excellent strength, durability, and corrosion resistance, making them ideal for transporting water at varying temperatures. Additionally, their flexibility allows them to withstand pressure and temperature changes, ensuring long-lasting and reliable performance in cooling water applications.

- Q: How do ductile iron pipes handle concentrated loads?

- Ductile iron pipes are specifically designed to handle concentrated loads effectively. Due to their unique composition and manufacturing process, they possess excellent strength and durability, making them highly resistant to cracking or breaking under heavy loads. One of the key characteristics of ductile iron pipes is their high tensile strength, which enables them to withstand concentrated loads without deformation. The pipes are made by adding small amounts of magnesium to cast iron during the production process, which transforms the brittle graphite flakes into nodular graphite. This modification significantly enhances the material's strength and ductility, allowing it to handle concentrated loads more effectively. Additionally, ductile iron pipes have a high modulus of elasticity, meaning they can deform elastically under a load and then return to their original shape once the load is removed. This property enables the pipes to distribute the concentrated load evenly along their entire length, minimizing stress concentrations and reducing the risk of fractures or failures. Furthermore, ductile iron pipes have a thick, robust wall thickness, providing them with exceptional structural integrity. This thickness allows the pipes to bear significant loads and withstand pressure variations without compromising their overall performance. In summary, ductile iron pipes are specifically engineered to handle concentrated loads due to their high tensile strength, elastic deformation capabilities, and thick wall thickness. These characteristics make them a reliable choice for various applications, including water and wastewater systems, as they can withstand significant external forces without compromising their structural integrity.

- Q: Can ductile iron pipes be used in areas with high levels of groundwater contamination?

- Yes, ductile iron pipes can be used in areas with high levels of groundwater contamination. Ductile iron is highly corrosion-resistant, making it suitable for such environments. Additionally, these pipes have a long lifespan and can withstand external pressures, making them a reliable choice for transporting water in contaminated areas.

Send your message to us

DI Pipe Fitting ISO2531/EN545/EN598,for water project

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords