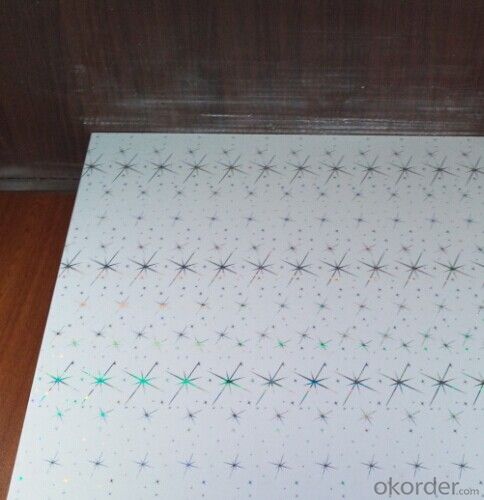

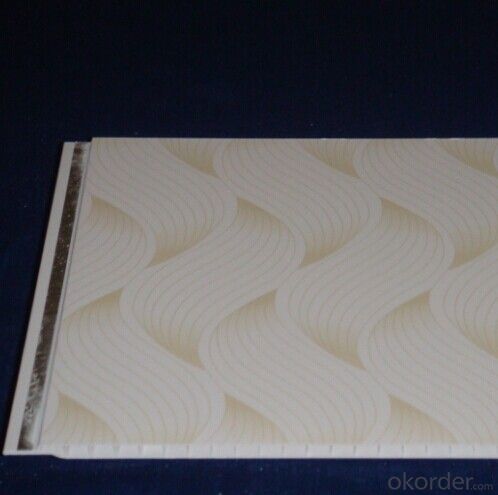

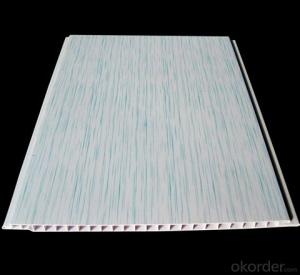

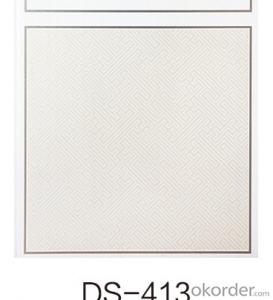

PVC Ceiling Western Cape - Decorative Building Materials Printing Ceiling PVC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

PVC Ceiling

1.PVC Panel

2.PVC Ceiling,PVC Wall Panel

3.Easy set & clean,Environment Protection

4.For Ceiling & wall Pane

Product Advantages:

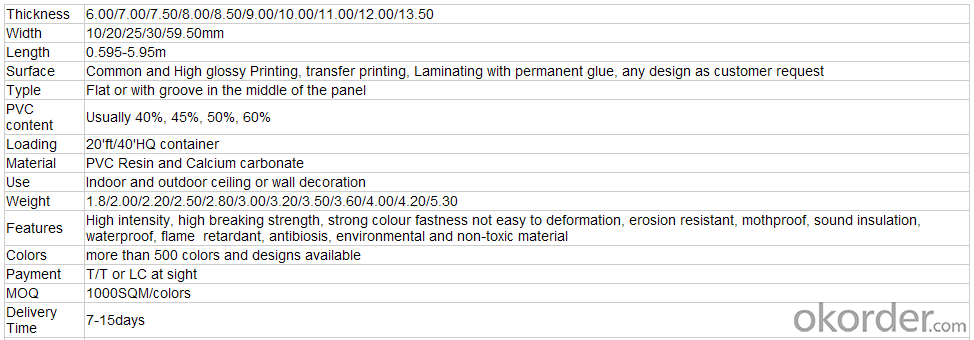

Main Materials and Specification

| Main Material | PVC Resin | |||

| Surface Treatment | Normal printing,Transfer Printing,Common glossy,High glossy | |||

| Size | Thickness(mm) | Width(cm) | Length(cm) | PVC Percentage |

| 9/9.5/10 | 10 | 5.8m for 20GP and 5.95m for 40GP or HQ or follow the customer's length requirement | 30% | |

| 8/8.5/9.0/9.5/10 | 16 | 35% | ||

| 5.0/6.5/7.0/7.5/8.0/8.5/9.0/10/11/12 | 20 | 40% | ||

| 5.0/6.5/7.0/7.5/8.0/8.5/9.0/10/11/12 | 25 | 45% | ||

| 7.0/7.5/8.0/9.0/9.5/10 | 30 | 50% | ||

| W30*80cm 8.0/8.5/9.0/9.5 | 60 | 60% | ||

| W60/60cm 7 | 60 | 65% | ||

Main Product Features:

1.Surface Treatment: High gloosy/printing/transfer printing,easy installation,smooth surface,flatness,without gap when concatenated

2.High intensity,high strength,not easy to deformation,resist erosion,sound insulation,waterproof,fireproof,aging-resisting,durable

3.Easy clearing,healthy and environmental

4.Can be processed by drilling,sawing,nailing

5.Hundreds of patterns & colors provided.New patterns are being continuously developed and updated,which can keep your leading position on the market

6.For hotels,commercial buildings,hospitals,schools,kitchens,bathroom and indoor decoration etc. Will be the excellent alternative material to decorate walls and ceilings effectively

7.All kinds of demand can be customed

8.Professional PVC panel manufaturer with 20 years experience.

Product Specifications:

Images:

- Q: Blister and PVC board distinction. Detailed description of the best.

- Blister board is an amorphous, odorless, non-toxic, highly transparent colorless or slightly yellow thermoplastic engineering plastics, with excellent physical and mechanical properties, especially excellent impact resistance, tensile strength, bending strength, compressive strength High stability, low stability, good heat resistance and low temperature resistance, in a wide temperature range with a stable mechanical properties, dimensional stability, electrical properties and flame retardant, can be in -60 ~ Long-term use at 120 ℃; no significant melting point, melting at 220-230 ℃ state; due to the large molecular chain, resin melt viscosity; small water absorption, small shrinkage, high dimensional accuracy, good dimensional stability, Oil resistance, but not resistant to ultraviolet light, good weather resistance; oil, acid, intolerant alkali, oxidizing acid and amine, ketones, soluble in chlorinated hydrocarbons and aromatic Solvent, long-term in water easily lead to hydrolysis and cracking, the disadvantage is due to poor fatigue strength, prone to stress cracking, solvent resistance is poor, poor wear resistance. PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate, is a vacuum plastic film. For all types of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC, according to the production process can be divided into PVC leather foam and PVC free foam board. General performance PVC resin is a white or light yellow powder, the relative density of 1.35-1.45. The softness of the product can be achieved by adding

- Q: How to weld PVC hard board

- The key lies in what you use PVC rigid accessories, because the inside of the additive is not good, it is not easy to weld! It is best to use point pvc improved type of additives! The better the degree of plasticization easier to weld!

- Q: Pvc board and rubber contact why fade?

- Production of PVC sheet on the use of toxic compound lead salt more stable, more cost-effective Baohua PVC efficient heat stabilizer patent series

- Q: At present home decoration used in white, beige panels have those? Type with PVC board?

- Similar to PVC is a polymer-free paint panel

- Q: What is PVC material?

- Polyvinyl chloride And polyvinyl chloride

- Q: What is the ignition of PVC?

- Generally about 256 ℃, the special temperature of 800 ℃.

- Q: PVC ceiling plate how to disassemble

- This is the carpentry technology live, but also some professional to do PVC ceiling professional live, if you do not do this line, it is difficult to remove, let alone installed, I first say how to demolition, if you handsome ability Should be demolished

- Q: PVC board surface a lot of white spots, what is the reason?

- I do not know what you use the material, if the use of PVC resin (not renewable material), then select a reasonable resin model, the formula should be reasonable, screw temperature, die temperature, calendering roller temperature (three rollers), raw materials must Control, drying is also critical.

- Q: Pvc foam board what materials?

- 1 PVC foam board, also known as snow Fu board and Andy board, the chemical composition of PVC. Features: 1. Waterproof, flame retardant, acid and alkali, moth, light, heat, noise, shock absorption characteristics; 2. And wood processing the same, and processing performance is far better than wood; 3. is the wood, aluminum, composite plate of the ideal alternative; 4. Leather surface is very smooth, high hardness, not easy to have scratches, commonly used in the production of cabinets, furniture and so on.

Send your message to us

PVC Ceiling Western Cape - Decorative Building Materials Printing Ceiling PVC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords