Decking Panel sutibale for outdoor made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item | Decking Panel-- China 10 Years Experience Composite Decking Suppliers |

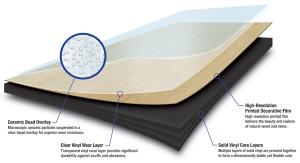

Material | Wood Plastic Composite |

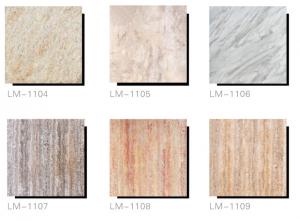

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

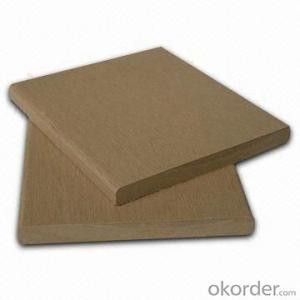

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Decking Panel

1. Eco-friendly, fully recyclable.

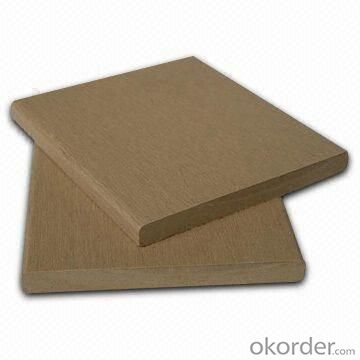

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

三. Picture of Decking Panel

四. Decking Panel Specification

Name | Decking Panel |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Decking Panel

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: What is the plastic floor and what is the compound floor?

- The floor has a new material composition, water resistance, generally suitable for public use. Composite floor, broadly speaking, refers to the structure of several layers of the composite floor, such as: laminate flooring, multi-layer solid wood flooring, bamboo flooring, etc..

- Q: Performance requirements for plastic flooring

- Water resistance. Resistance to washing, no deformation, loss of light, fading, etc..4, dimensional stability. The size of the bulk floor has strict requirements.

- Q: How to eliminate the smell of plastic floor

- No special way to remove the taste is the plastic floor itself distributed, you shop this must be afraid of children playing on the ground fall

- Q: Floor mounted mats are not ordinary plastic films?

- In addition, there is also the original pad overlap in 20mm joints, and tape sealing, although also can achieve similar waterproof effect, but the cushion thickness of 2mm or so, the overlap will have high low, easy to produce noise floor installation. The thickness of plastic film is only about 0.1mm, although the overlap will not produce high and low, no effect on the pavement.

- Q: That is, after the lime on the ground after the laying of plastic sheeting and then spread the concrete above the floor tiles on the floor so good? Do not put it or put it (plastic cloth)

- What do you do with the clinker, waterproof? No, I do not recommend when tile put cloth cloth with no clinker clinker, the original ground firmly fixed, after you tile paste, there will be many problems, such as hollowing.

- Q: Basketball court assembled plastic floor why pack

- Suspension flooring: 1 special matte technology, 2 green, 3 simple and convenient installation, assembling 4 basketball versatility, 5 wear non slip durability, high ratio of 6, 7 low maintenance cost.

- Q: The floor of the wooden floor is a good line of plastic or wood

- Plastic bar, wood is worried that the water will become black and ugly

- Q: Dog feces in the plastic floor on how to clean, 84, washing powder, detergent are used, or brush off, how to do? What cleaning

- Select the plastic floor must choose the site dedicated, the wrong choice of use and material life, you know! There are many types of plastic floor, mainly divided into coil and sheet, is the most common material, plastic sheet flooring series of thousands of species, like the current popular commercial floor: PVC floor (such as shopping mall (supermarket), hotel, hotel, hospital, school, kindergarten, family, office, commercial airport... Site

- Q: Plastic floor paper how much a square

- Construction of the human resources (some special circumstances, the need for more manpower)

- Q: PVC plastic floor can be used as a kitchen operating room, right?

- 1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factory, school, hotel, hotel

Send your message to us

Decking Panel sutibale for outdoor made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords