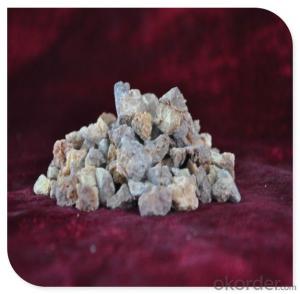

Raw Materials for Refractory:Dead Burnt Magnesite (MgO 88-92%) Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China | Brand Name: | CNBM |

Packaging & Delivery

| Packaging Details: | as per buyer choice |

| Delivery Detail: | After LC confrmation 20 days. |

Specifications

Dead Burned Magnesite

Used for refractory materials.

MGO:86-90%min and 91-95%

Size;0-5mm,0-3mm,1-5mm and+

Dead Burnt Magnesite

Used for refractory Materials,

Mgo,----------- 88-90%min, and 90-95%

Sio2,----------- 4.5%max.

Cao,------------2.5% max.

Fe203,-------- 1.5% max.

Al,---------------1.5%max.

Loi,--------- ----1%max

B.D,-------------3.15%

Size; 0-2mm, 0-5mm and others

Paking; 50 Kgs , and than into 1000 Kgs bags or, as per buyer choice.

Payment; LC at sight, with 30% advance and 70% after BL.

Note: We can also produce Fluorspar 80% and white talc of 95% whiteness.

Basic Information

| Business Type: | Manufacturer, Trading Company | |

| Main Products: | Flourspar Lumps,Talc Lumps garephite,chrome ore copper ore,manganese ore Mica,DBM | |

| Number Of Employees: | 11 - 50 People |

Trade & Market

| Main Markets: | Western Europe Eastern Asia Mid East Southeast Asia Eastern Europe North America | |

| Total Annual Sales Volume: | Below US$1 Million | |

| Export Percentage: | 81% - 90% |

Factory Information

| Factory Size (Sq.meters): | 1,000-3,000 square meters | |

| Factory Location: | peshawar, NWFP, Pakistan | |

| No. of Production Lines: | 6 | |

| Number of R&D Staff: | 5 - 10 People | |

| Number of QC Staff: | 21 - 30 People | |

| Contract Manufacturing: | CNBM |

- Q: What materials is silicious thermal insulation board made of?

- Siliceous insulating panels use quartz sand as the main material and are composited with fiber. Of course the amount of insulation board materials used by different companies is different. In terms of Hua Heng, siliceous insulating boards can be divided into insulating panels for casting slabs and insulation board for intermediate tank according to the usage. The latter one can be divided into liner plate (wallboard, side panels, baseboard) and impingement plate based on parts it is used on. Siliceous insulating panels use quartz sand as the main material and are composited with fiber. Method for manufacturing a silicon insulating panel is divided into semi-dry method and wet method. It is used for casting ingot insulation cap of the killed steel and continuous casting tundish.

- Q: What's the feature of construction external wall fireproof and thermal inuslation matertial?

- Building external wall fireproof thermal insulation material is made by stirring, casting, foam protecting and cutting with industrial by-product gypsum as the main raw material, adding sulphate aluminium cement, fly-ash, polymer additives and other materials. It has excellent properties of respiratory function , air permeability, water impermeability, recycling system data, wind load resistance, shock resistance, thermal insulation, fireproof and sound insulation.

- Q: Do you know what the main indicators are for the inspection of refractory materials? Thank you very much for your requests and reports

- The main indicators of refractory material inspection must be fire resistance materials, flame retardant, a subdivision of lecture, ignite the smoke toxicity, smoke density, heat release and flue gas;

- Q: How to use fireclay?

- Fire-resistant adhesive material is needed, its effect equals to the cement. Cement will certainly do.

- Q: Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q: How long is the fire resistance time of the AAAfire resistance rolling shutter door?

- How long is the fire resistance time of the AAA fire resistance rolling shutter door?

- Q: What are the requirements when producing fireproof materials by kaolin?

- Kaolin refractories in fact play a role in two aspects, one is to improve the refractoriness, the second is to improve plasticity of the the refractory . Aluminum content the higher the better, of course, but kaolin is not the only material to improve the content of aluminum, using materials that contain higher content of aluminum such as the bauxite chamotte. So the content of kaolin aluminum does not have to be too high. over 38% is fine. viscosity is important and strong viscidityis better without having to add bentonite. Refractoriness above 1400 degrees is enough.

- Q: What kinds of refractory materials that uses a-Al2o3 powder? What are the purpose of it?

- 04La-Al2O3 powder is a alumina powder whose raw material is industrial aluminum oxide which has been calcined at high temperature. It is a good polishes for ceramics and jade, meanwhile, it is also an important raw material for high-end refractory materials. The technical indicators parameters A1023 mark A1535 chemical composition AL2O3≥ 99.92 3%, ≥ 3.10FE203≤ 0.799 Refractory calcined alumina powder (a-Al2O3) 1.2 true density (g & # 47, by fully ground powder made of different fineness .O.10 0.07 0.04NA2O≤ 0.93a-Al2O3 (%) ≥ 95 95 primary crystallization average grain (um) 2 ~ 3 3 ~ 5 average particle size (um) 40 ~ 602.6SIO2≤ 0.1 0.15B2O3≤ - 0, glass, engineering ceramics typical use electronic ceramic insulating ceramic refractory ceramic wear 3

- Q: what materials can make external wall fireproofing paint have the fireproofing effect

- Adding flame retardant or fire retardant materials can be fireproofing, which commonly referred to as the external walls of fire retardant coating or fire retardant coating. Principle: Fireproof paint itself is flame-retardant or non-combustible, so that the protected base material can not directly contact with the air in order to the ignition delay and reducing the burning speed; except that, it also has a lower thermal conductivity, which can delay the transfer of flame temperature to the protected base material; fireproof paint thermal can decompose non-combustible inert gas by heating to dilute the thermal decomposition of combustible gas in protected object, making it difficult to burn or slow down the speed of burning.

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite (MgO 88-92%) Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords