Dead-Burned Magnesite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

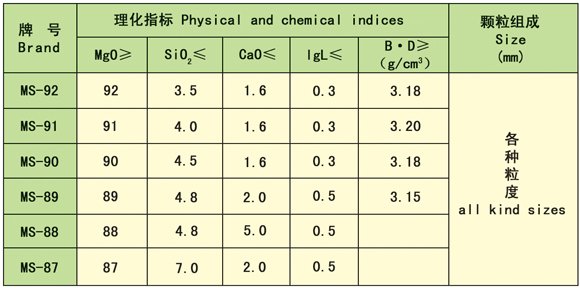

| Place of Origin: | Liaoning, China (Mainland) | Shape: | Block | SiO2 Content (%): | 3.5-7.0 |

| MgO Content (%): | 87-92 | CaO Content (%): | 1.6-5.0 | Model Number: | M-DBM |

| Brand Name: | CNBM |

Packaging & Delivery

| Packaging Details: | 10-25kilogram 5 layers craft paper bags, the craft paper and plastic compound bags; 40-50 kilograms PP bag, 500 and 1000 kilograms PP bag packing. We can also pack according to users' requirements |

| Delivery Detail: | Within 1 month |

Specifications

1.High purity Large crystal grain Compact structure

2.Strong resistance to slag material

3.Good thermal shock resistance

Dead-burned magnesite is selected from natural magnesite, it is produced by mine-selecting, purifying, calcining in shaft kiln. It is an ideal material for unshaped refractory material, the final products are used in open hearth furnace, eletric furnace bottom and furace's lining tamping.

Details are as follows:

Our company has processed various kinds of magnesia. As 20 years passing, our products of magnesite are widely used in many industrial fields of areas the world. Any question, please feel freely to contact us.

Magnesia is divided into sintered magnesia, light burned magnesia, fused magnesia three categories.Magnesia refractory material is one of the most important raw materials, aluminum used in the manufacture of all kinds of magnesite brick, magnesite brick, ramming material, repairing, etc.Contain a more impurities, are used to construct steel furnace bottom, etc.Sand in the main ingredients for magnesium oxide, impurities such as CaO, SiO2, Fe2O3, magnesium oxide as basic oxide, melting point is 2800 degrees, after the high temperature heating into stable cubic crystal, commonly known as periclase.By magnesium hydroxide by high temperature calcination, hydration resistance ability.Sintered magnesia is mainly composed of magnesite, magnesite or water from the water extract of magnesium hydroxide by high temperature calcination.Hydration resistance ability.Magnesite calcination under 700-950 ℃ is escaping CO2, magnesite as soft porous loose material, cannot be used for refractory material;Magnesite through 1550-1600 ℃ calcination so-called burned magnesia said sintered magnesite.Light burning magnesium powder is bending, compression, high strength, hard, gelled material, widely used in national defense, medicine, chemical industry, paper making, shipbuilding and other industries.In the building materials industry produce tire sub board, particle board, heat preservation columns, railing, artificial marble, asbestos tile, ordinary tiles, wall panel, laying on the ground.With the progress of science and technology, light burning magnesium powder application more widely, civil products, light and heavy machinery packing boxes, packaging can do sill, high-temperature refractory material, also can make beautiful luster strong furniture, in the machinery industry to do model.

- Q: what's the seal of fireproofing material?

- Folded organic putty takes organic material as bond,it has certain flexibility or plasticity while using, and it's products are thick liquid or cement shaped object. Folded WXY-II is powered?solid that takes inorganic materials as main components, it has certain workability while used with admixture. Folded fire retardant bag is the packaged object made by fireproofing material, and it's suitable for fireproofing seal of larger openings or fire separation of cable?bridge(fire retardant bag also refers to fireproof bag) Folded fire retardant module is the solid made by fireproofing material with certain shape and size, and it is easy for cutting and drilling, suitable for fireproofing seal of opening and cable?bridge. Folded seal board is made by fireproofing material, it's easy for cutting and drilling, suitable for fireproofing seal of large opening. Folded foam seal is a kind of fireproofing material that can automatically expand and foam and sealed by opening after injecting the foam into opening. Folded sealing strip is a product or flexibility coiled material mede by fireproofing material with certain geometry shape. Folded sealing gum is a kind of liquid fireproofing material that has a function of fireproofing and sealing. Folded fire retardant bag is soft and windable tape-shaped product made by fireproofing material, it is winded on the external surface of plastic pipe and fixed with steel belt or other proper methods, it's the expansion, squeezing and softening pipe after contacting with fire, opening left by burning or soften of seal plastic pipe. Folded fire retardant ring is the product made by fireproofing material and metal shell, it's covered on the external surface of the plastic pipe, expanding and sealing after contacing with open fire, the opening left by burning and soften of plastic pipe when it passes through the opening of wall and floor.

- Q: What's the maximum temperature that the refractory ceramic fiber cloth can endure?

- While the refractory ceramic fiber cloth is different in high temperature resistance, and in general it can endure the high temperature of more than 1000℃. Ceramics in daily use and art ceramics: Bone china and Guangdong chinaware can generally endure the highest temperature of 1100℃. Jingdezhen porcelain and ceramics: They can generally endure the highest temperature of 1280℃-1340℃, and some special ones can endure the highest temperature of 1400℃. Industrial ceramics: Some of them can endure the highest temperature of about 2600℃. (alumina ceramics: their melting point is 2050℃, and boiling point is 3000℃).

- Q: Who knows about the criteria of fireproof and thermal insulation materials?

- Seven levels are divided according to "The classification of combustion performance of building materials and products", namely, A1, A2, B, C, D, E, F. It mainly refers to the combustion performance of materials. You can check on this standard for the specific dividing evidence. There are detail charts which mainly describe that whether there is drip or not, the ignition time, continuous burning time and so on.

- Q: What needs to be noted when choosing and using blast furnace fireproof materials? Who knows?

- there are different temperatures in various parts of the blast furnace, thus using different types of refractory.

- Q: who knows how to classify the fire resistant levels of fireproofing material?

- Materials used in construction are called construction materials. The combustion performance of construction materials refers to all physic and chemical changes happened when burning or contacting fire, the properity is measured by combustibility of material surface and flame transmission, heating, smoke,charring, weightlessness, and the producing of toxicity resultant. Our national standard GB8624-97 classifies the combustion performance of construction materials into following several levels. Class A: Incombustible building material, class B1: Nonflammable building material, class B2: Combustible?building?materials, class B3: Inflammability construction materials, generally speaking: first fire resistant level construction is the mixed construction of reinforced concrete structure or brick wall and steel concrete structure; second fire resistant level construction is the steel structure roof truss, reinforced concrete column or mixed structure made by brick wall; third fire resistant level construction is the wood and brick made by wooden roof and brick wall; fourth fire resistant level one is the combustible?structure made by wooden roof, hard-comnustible component wall.

- Q: what is the common materials for home fireproofing material?

- 1, lumber core 2,decoration panel 3 , plywood 4 density board 5,chipboard 6 fireproof?panel, 7.gypsum board Hope to adopt my opinion

- Q: What are the differences between first-level fire-resistant materials and second-level fire-resistant materials?

- Level B1: building materials with flame retardancy: this kinds of materials have good effect in flame retardation. Under the case of open fire or high temperature, it is not easy to be ignited and spread quickly, and when the fire source is removed, fire would stop immediately. Level B2: combustible building materials: combustible building materials also have effect in flame retardation. It will get burnt as soon as it meets open fire or high temperature, so it can easily give rise to rampant fire, such as wooden pillars, wood roof trusses and wooden stairs.

- Q: What are the differences between thermal?insulation?material and refractory?

- Just as its name implies, Thermal insulation means that it doesn't conduct heat instead it insulates heat inside, while refractory means resistance to high temperature and it will not be out of shape or damaged due to high temperature.

- Q: I wanna ask about the thermal insulation material fire resistant level?

- The inorganic have glass wool \ foam glass Bian \ the best of organic is phenolic foam \ phenolic foam composite cement layer is level A.

- Q: What are the uses of refractory materials of glass furnace?

- crown--high-purity silica bricks; wall--melting end 41# fused zirconia corundum bricks with no shrinkages(41% of zirconium, similarly hereinafter), cooling end 33# fused zirconia corundum bricks with no shrinkages; bottom--33# fused zirconia corundum bricks(with shrinkages); breastwork--33# fused zirconia corundum bricks(with shrinkages); port--33# fused zirconia corundum bricks(with shrinkages); regenerator chamber--the upper part is for magnesite-chrome bricks, the bottom part is for high-duty fireclay bricks; checker--the upper part is for high purity magnesia bricks, and the bottom part is for magnesite-chrome bricks; flue--clay bricks. This is the best configuration. If the funds are limited, the configuration can be lowered, for example, the wall will be changed to 38 #......

Send your message to us

Dead-Burned Magnesite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords