Customized Painted Aluminum Coil - Aluminium Roofing Sheet/Coil in Competitive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

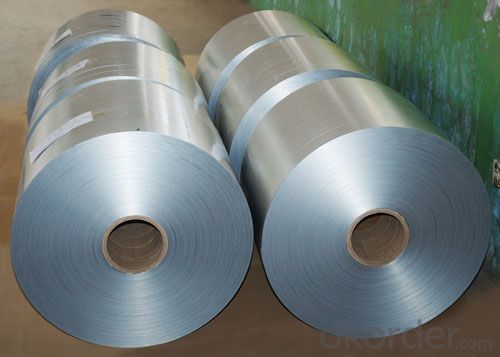

Aluminium Roofing Sheet/Coil In Competitive

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: Can aluminum coils be customized in terms of thickness?

- Aluminum coils can indeed undergo customization in terms of thickness. The specific requirements of a particular application can determine the adjustment of aluminum coils' thickness. This customization is attained through the process of aluminum coil slitting, which involves cutting the original coil into narrower coils of the desired thickness. This method enables the flexibility to meet a range of needs and specifications across diverse industries.

- Q: Can aluminum coils be used in chemical processing plants?

- Indeed, chemical processing plants can utilize aluminum coils. Aluminum, a versatile and extensively employed substance across multiple industries, including chemical processing, boasts exceptional resistance to corrosion. Consequently, it proves apt for the manipulation and conveyance of diverse chemicals. The application of aluminum coils extends to heat exchangers, condensers, evaporators, and other chemical processing equipment. Moreover, aluminum coils boast a lightweight nature and exhibit high thermal conductivity, promoting efficient heat transfer and energy conservation. Nevertheless, it remains crucial to carefully evaluate the specific demands and compatibility of the chemicals being processed to ascertain the suitability of aluminum coils for the intended use.

- Q: The temperature of the water drops from 93.0°C to 78.0°C. What quantity of heat energy did the piece of aluminum absorb?

- The specific heat of Aluminum is 0.215 cal/g-°C. The calories absorbed (q) would be q = m * c * (T2 -T1) = 22.0 g * 0.215 cal/g-°C * (78.0 °C - 0.3 °C) If you have a different value for the Specific heat of Aluminum, use it in the formula for your calculations. If you knew the mass of the water, you could check your calculations because the heat gained by the Al would be equal to the heat lost by the water, using q = m * c * (T2 -T1), where m is the mass of the water, c = 1.00 calorie/gram °C, T2 = 78.0 °C and T1 = 93.0 °C. The sign of q will be negative.

- Q: Can aluminum coils be used in HVAC heat exchangers?

- Yes, aluminum coils can be used in HVAC heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It allows for efficient heat transfer and is often preferred over other materials like copper in certain HVAC applications.

- Q: How does aluminum ingot be processed to aluminum coil (aluminum sheet)?

- First it should be made into blank and then put on the rolling mill.

- Q: What are the different types of surface coatings for aluminum coils?

- There are several types of surface coatings available for aluminum coils, including polyester, polyvinylidene fluoride (PVDF), epoxy, acrylic, and plastisol. Each coating offers unique properties such as durability, weather resistance, chemical resistance, and color retention. The choice of coating depends on the intended application and the specific requirements of the aluminum coil.

- Q: What does 1060 of the 1060 Aluminum rolls stand for?

- Purity can reach more than 99%. Because it does not contain other technical elements, the production process is relatively simple, and the price is relatively cheap. It is the most commonly used series in the conventional industries.

- Q: Can aluminum coils withstand high temperatures?

- Yes, aluminum coils can withstand high temperatures. Aluminum has a relatively high melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). This makes it suitable for applications that involve high-temperature environments. Additionally, aluminum has excellent thermal conductivity, which allows it to dissipate heat efficiently. This property makes aluminum coils commonly used in heat exchangers and various heating applications. However, it is important to note that the specific temperature limit for aluminum coils may vary depending on the specific alloy and application.

- Q: How are aluminum coils used in signage and advertising?

- Aluminum coils are commonly used in signage and advertising due to their versatility, durability, and cost-effectiveness. These coils are typically used to create sign panels that can be found in various settings, such as billboards, retail stores, airports, and public spaces. One of the main advantages of using aluminum coils in signage is their lightweight nature. This allows for easier installation and transportation, making it a preferred option for large-scale outdoor advertisements like billboards. Additionally, aluminum coils can be easily shaped and molded into different forms, allowing for creative and eye-catching designs that can effectively grab attention. Due to their durability, aluminum coils are highly resistant to weather conditions, including harsh sunlight, rain, and snow. This makes them ideal for outdoor signage that needs to withstand the elements. The material's corrosion resistance also ensures that the signage will maintain its appearance over time, extending its lifespan and reducing maintenance costs. Furthermore, aluminum coils can be coated or painted with different finishes, allowing for customization and branding. These finishes can range from vibrant colors to reflective or brushed effects, enhancing the visual impact of the signage. The smooth surface of aluminum coils also provides an excellent base for printing graphics and logos, resulting in high-quality and vibrant imagery. In terms of cost-effectiveness, aluminum coils are relatively affordable compared to other materials commonly used in signage, such as steel or plastic. The lightweight nature of aluminum also reduces shipping costs and simplifies installation, saving time and money for businesses or advertisers. Overall, aluminum coils play a crucial role in the signage and advertising industry, offering a versatile, durable, and cost-effective solution for creating visually appealing and long-lasting signs. Their lightweight nature, resistance to weather conditions, customizable finishes, and affordability make them a popular choice for a wide range of signage applications.

- Q: What are the different coil winding methods for aluminum coils?

- There are several different coil winding methods for aluminum coils, each with its own advantages and suitability for specific applications. 1. Layer winding: This method involves winding the aluminum wire in a single layer around the coil mandrel. It is commonly used in low voltage applications and provides good thermal conductivity and heat dissipation. 2. Random winding: In this method, the aluminum wire is wound randomly around the coil mandrel, without any specific pattern. It is often used in high voltage applications, as it helps to reduce the risk of corona discharge and provides better insulation. 3. Concentric winding: As the name suggests, concentric winding involves winding the aluminum wire in concentric circles around the coil mandrel. This method is suitable for applications where space is limited, as it allows for a higher number of turns in a compact coil. 4. Interleaved winding: Interleaved winding involves winding multiple layers of aluminum wire in an interleaved pattern. This method helps to reduce the overall size of the coil while maintaining a high number of turns and increasing the inductance. 5. Helical winding: In helical winding, the aluminum wire is wound in a helix pattern, either at a constant pitch or with varying pitch. This method is often used in applications where a high inductance is required, such as inductors and transformers. 6. Sectional winding: Sectional winding involves dividing the coil into multiple sections and winding each section separately. This method is commonly used in large-scale applications, as it allows for easier handling and installation of the coil. Each of these coil winding methods has its own strengths and considerations, and the choice of method depends on factors such as the specific application requirements, space limitations, and desired electrical characteristics.

Send your message to us

Customized Painted Aluminum Coil - Aluminium Roofing Sheet/Coil in Competitive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords